41

2 6 6 H S H MODBUS TR A N S M IT TE R |

P R E SSU R E/ T EM P ER AT U R E M U LT I VA R I A B L E | O I/ 2 6 6 H SH M T- EN R E V. A

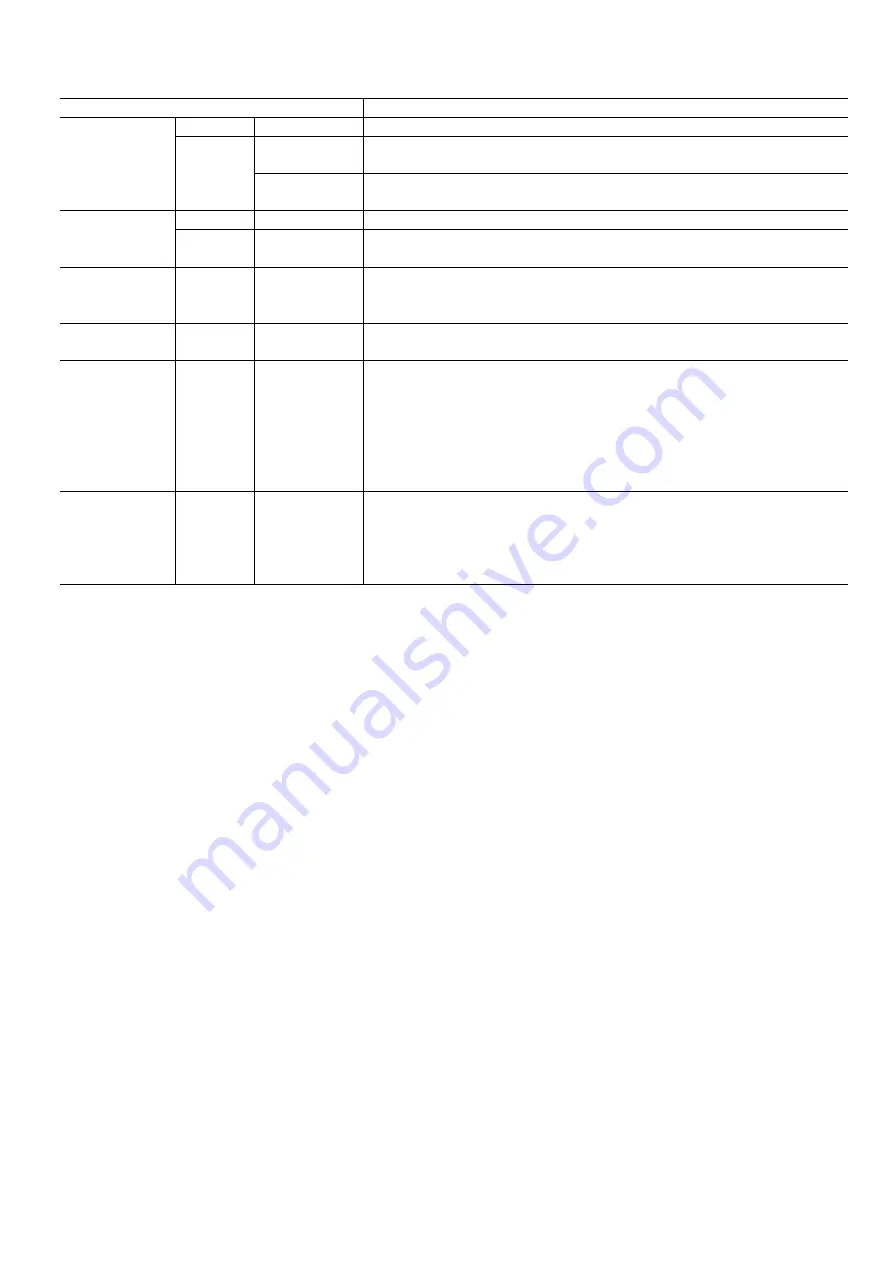

— Respect the below table indications for reinstalling the process flanges.

T

ransmitter model and range

Procedure

266DSH / PSH / VSH

Viton Gaskets All bolting

Use a torque wrench to tighten the bolts to a torque of 25 Nm.

PTFE Gaskets

Carbon Steel NACE

and Stainless Steel

Use a torque wrench to tighten the process flange nuts to a torque of 40 Nm, let the flange

stabilize for an hour, unscrew the nuts and tighten again to 25 Nm.

Stainless Steel

NACE

Use a torque wrench to tighten the process flange nuts to a torque of 25 Nm, let the flange

stabilize for an hour and perform the final tightening to 25 Nm.

266DSH.x.H

(High static option)

Viton Gaskets All bolting

Use a torque wrench to tighten the bolts to a torque of 31 Nm.

PTFE Gaskets All bolting

Use a torque wrench to tighten the process flange nuts to a torque of 40 Nm, let the flange

stabilize for an hour, unscrew the nuts and tighten again to 31 Nm.

266DSH range A

(1KPa)

All gaskets

All bolting

Use a torque wrench to tighten the process flange screws/nuts to a torque of 14 Nm.

Please be aware that in case of bottom work disassembly and reassembly the original

performances can not be guarantee anymore.

266DSH / 266PSH

with Kynar inserts

All gaskets

All bolting

Use a torque wrench to tighten the process flange screws/nuts to a torque of 15 Nm

266MSx / 266RSx

MWP ≤ 41Mpa /

410bar / 5945 psi

All gaskets

All bolting

First, use a torque wrench to tighten the process flange screws/nuts to a joining

torque of — MJ = 2 Nm (0.2 kpm), working in a crosswise manner.

— Then tighten them with a torque MJ = 10 Nm (1.0 kpm), working in a crosswise

manner — Then tighten them fully by turning each nut or screw again (in a

crosswise manner) by the tightening angle A = 180°, working in two stages of 90°

each. Some transmitter versions are using screws with size M10. If this screws are

used the tightening angle A = 270°, working in three stages of 90° each.

266MSx / 266RSx

MWP 60Mpa /

600bar / 8700 psi

Perbunan

All bolting

First, use a torque wrench to tighten the process flange screws/nuts to a joining

torque of — MJ = 2 Nm (0,2 kpm), working in a crosswise manner.

— Then tighten them with a torque MJ = 10 Nm (1,0 kpm), working in a crosswise

manner — Then tighten them fully by turning each nut or screw again (in a crosswise

manner) by the tightening angle A = 180°, working in two stages of 90° each.

9.4 Pressure transducer replacement

If the pressure transducer needs to be replaced proceed as

follows:

1. Insulate the transmitter from the process by acting on

the manifolds or on the insulation valves.

2. Open the vent valves to allow sensor depressurization.

3. Disconnect the power supply and disconnect the

wiring.

4. Disconnect the transmitter from the bracket

unscrewing the fixing bolts.

5. Open the communication board compartment cover.

6. The communication board is connected to the sensor

via a flat cable and a connector. Remove the

communication board and gently disconnect the

connector.

7. Release the tang screw until nd rotate the housing until

its complete removal.

8. Unscrew the fixing bolts from the transducer and

remove the process flanges.

9. The orings placed between the diaphragm and the

flange (Viton or PTFE) must be replaced after every

disassembly.

10. Reassemble the flanges following the steps above in

reverse order.

11. The 266 can reconfigure itself with the previous

configured parameters thanks to the auto-

configuration functionality.

12. Before powering on the transmitter raise dip-switches

1 and 2 in up position. Connect the transmitter to

power supply, wait ten seconds and lower dip-

switched 1 and 2.

13. After installing the transmitter on the bracket and

connecting it to the manifold, perform a PV zero bias.

9.5 Electronic replacement

If the electronic module needs to be replaced proceed as

follows:

1. Insulate the transmitter from the process by acting on

the manifolds or on the insulation valves.

2. Open the vent valves to allow sensor depressurization.

3. Disconnect the power supply and disconnect the

wiring.

4. Open the communication board compartment cover

and remove the LCD display (if installed).

5. Remove the communication board and gently

disconnect the connector.

6. Connect the sensor flat cable to the new electronic

module with dip switch 1 in up position.

7. Connect the transmitter to power supply, wait ten