GETTING A GOOD FIRST LAYER

The first layer IS the most important layer of any print and perhaps

the most difficult. A good first layer is vital to the success of your

print.

Qualities of a good first layer include:

•

Clean (clear of debris), prepared glass.

•

Sticky build plate

•

Proper bed temperature.

•

Optimal first layer nozzle height

A good first layer adheres to the print bed, is the correct distance

from the print bed, is visibly smooth and level, without gaps or

bumps.

Here are a few tips for getting a good first layer:

•

Make sure the print bed is level.

•

Prepare the glass using fixative spray.

•

Adjust the build plate height while printing fisrt layer

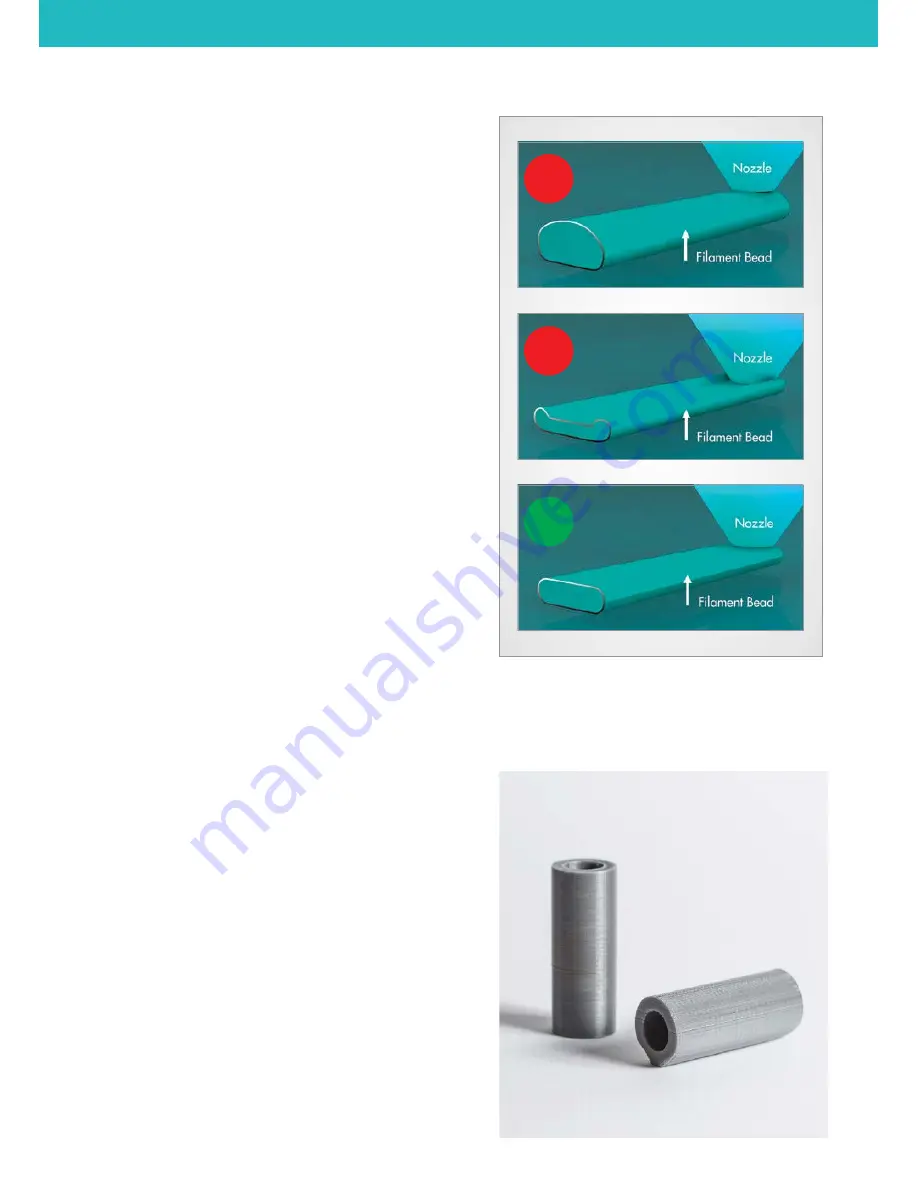

Getting the first layer height dialed in is critical

•

If the first layer is too high and it will not stick.

•

If the first layer is too low it will create a valley, and may drag

the nozzle on the glass.

The first layer height is correct when the bead of filament is

flattened slightly and even.

•

Heat the print bed to the recommended temperature base

upon the material being used.

If adhesion problems persist:

•

Increase bed temperature to 80-85º C

•

Increase the nozzle temperature by 10-20º C for the first 1-3

layers to aid in adhesion.

•

Decrease the printing speed by 30% for the first layer

•

Increase the flow rate by 5-10% for the first layer

•

Print a test print to ensure good first layer adhesion

Gap Too Large

Gap Too Small

Correct Gap

Stop

Stop

Go

ATLAS SERIES

Printing Tips

26

ORIENTING THE PART

Part orientation—the direction the part is positioned

on the print bed—effects the print quality, print time,

surface finish, and overall print-ability of the model.

The following tips are intended to assist in orienting your part

for a successful print:

• Position so the most surface area is in level contact

with the print bed.

• If possible, orient the part to reduce or eliminate

support structures.

• Consider surface finish. Which part of the model is

most important? Position the part accordingly.

• Reducing support structures will reduce print time.

• When break-away support structures are used

directly on the print bed, the use of a raft may be

necessary to avoid adhesion problems.