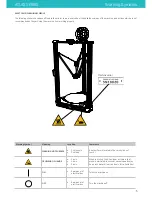

CHANGING NOZZLE

The extruder is hot, handle with care

Do not touch the heater cables with metal while heating is on.

Do not turn off the machine if the hotend temperature is above 50°C

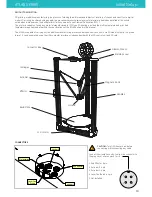

Tools needed:

•

7 mm wrench or Socket Wrench

•

Crescent wrench

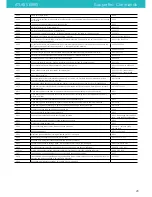

When installing the nozzle make sure that the nozzle and the heat break mate up inside the heater block, this is needed to prevent leakage

and filament jams.

An indication of succesful mating is resulting gap between the nozzle and the heater block after thightening the nozzle.

1. Preheat the hotend

2.

Unload the filament

3. Set the extruder nozzle temperature to 200º C. This will melt any plastic inside the extruder and loosen the nozzle.

4. Once the temperature has reached 200º C, use a crescent wrench and 7 mm wrench to remove the nozzle. Use the crescent wrench

to hold the base steady and not able to rotate. Use caution—nozzle is hot!

5. Once nozzle is removed select the replacement nozzle. Nozzle size can be determined by inspecting stamped numbers along the side

of the nozzle.

6. Once new nozzle has been selected, hand thread it into the extruder.

7. Then use the wrench and crescent wrench to tighten the nozzle into the assembly, only tighten until snug.

DO NOT OVER TIGHTEN.

8.

Once nozzle is tightened, set the extruder temperature from 200º C to 280º C. This will heat up the nozzle and ensure it has a tight fit.

9. Once the temperature has reached 280º C, use the wrench and crescent wrench to tighten the nozzle so it is snug.

GAP

HEATBREAK AND

HEATER BLOCK ALIGNED

HEATBREAK AND

NOZZLE MUST MATE

When reinsterting the PTFE tube make sure its fully inside

the extruder.

ATLAS SERIES

Operating

18