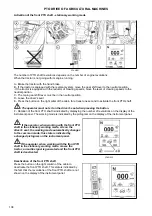

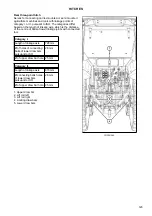

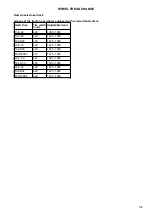

Connecting machines and tools to External hydraulic circuit

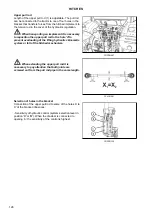

Connecting a double acting cylinder

A double acting cylinder must always be connected to quick couplers of one section.

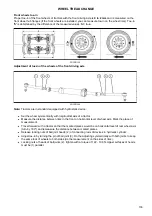

Connecting machinery and tools assembled from more parts

When working with agriculture machinery which is assembled from more parts (combinators, scrubbers, or

harrows) where the edge frame is hinged to the central frame because it is diagonally folded during transport

by independent hydraulic cylinders which are controlled by outer hydraulic circuit of the tractor, it is

recommended to connect the lifting arms of the cylinders to quick couplers (3) and (5) which are equipped

with a one-way valve.

Connecting rotary hydraulic engine

If a hydraulic engine is connected to outer hydraulic drive, it is always necessary to connect its returnable

arm to quick coupler (0). Filling (pressure) arm can be connected to quick couplers (1) or (2), where the

hydraulic engine is protected by the 'kick-out' function from overload. This function stops the hydraulic engine

if pressure in the filling arm exceeds 17 MPa.

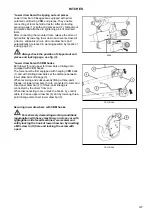

Connecting reverse rotary hydraulic engine

Due to its function, reverse rotary hydraulic engine must be connected to quick couplers of one section. It is

recommended to use quick couplers (1) and (2), where the hydraulic engine is protected by the 'kick-out'

function from overload. This function stops the hydraulic engine if pressure in the filling arm exceeds 17

MPa. If the hydraulic engine is connected to quick couplers of different sections, both arms must be

equipped with safety valves which can be relied on to restrict high pressure peaks during run-out. Connect

the safety valves drain to quick coupler (0).

Connecting external hydraulic distributor

It is recommend to connect external hydraulic distributor to quick couplers (4) or (6). Control levers (b) and

(c) are mechanically locked in these positions without hydraulic lock.

Auxiliary machines using oil filling of external hydraulic circuit must be filled with the same

kind of oil, which is recommended for gear system of the tractor! Quick-couplers sockets of an

auxiliary machine need to be properly cleaned before connecting.

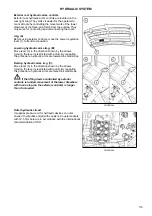

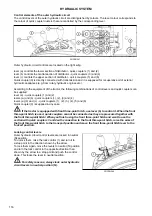

HYDRAULIC SYSTEM

122

Summary of Contents for Proxima CL 80

Page 1: ...OPERATOR S MANUAL PROXIMA CL 03 2018 Tractor is Zetor Since 1946 80 90 100 110...

Page 3: ...2...

Page 11: ...10...

Page 33: ...NOTES 32...

Page 91: ...NOTES 90...

Page 111: ...NOTES 110...

Page 131: ...NOTES 130...

Page 147: ...Fuse panel B P18N083 ELECTRICAL INSTALLATION 146...

Page 163: ...NOTES 162...

Page 181: ...NOTES 180...

Page 187: ...NOTES 186...

Page 203: ...NOTES 202...

Page 208: ...207...