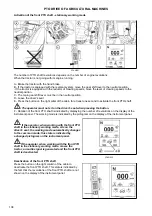

Display of revolutions of PTO shafts

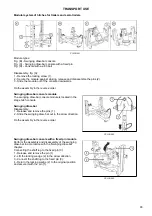

Replaceable end points of rear PTO shaft

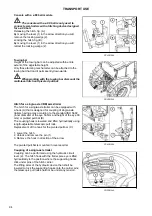

(1) - In case that the tractor is equipped with the front PTO

shaft, the revolutions of the front PTO shaft are shown on

the display of the instrument panel after switching the front

PTO shaft with the button on the right column of the cabin

and rotation of the front PTO shaft.

(2) - If independent revolutions of the rear PTO are

shifted, the revolutions of the rear PTO shaft are shown on

the display of the instrument panel after switching the rear

PTO shaft with the button on the right column of the cabin

and rotation of the rear PTO shaft.

If dependent revolutions of the rear PTO shaft

are shifted, the revolutions are not shown on the

display of the instrument panel.

P18N015

The tractor is equipped with six or twenty-one splined

replaceable end point of rear PTO shaft.

Replacement procedure:

1. Use safety ring pliers to demount a safety ring (1)

2. Remove replaceable end point by pulling in the

direction of an arrow (2)

3. Mount the end point in an opposite way, pay increased

attention to the mounting of the safety ring (1)

Replacement of the terminal shall be performed

when the engine is stopped.

Rpm of the output shaft and terminal type shall be

chosen depending on the prescribed rpm of the

coupled mechanism.

Shifting 540 and 1,000 or 540E min

-1

is possible

regardless to the number of splines of the installed

terminal.

E357

PTO DRIVE OF AGRICULTURAL MACHINES

99

Summary of Contents for Proxima CL 100

Page 1: ...OPERATOR S MANUAL PROXIMA CL 03 2018 Tractor is Zetor Since 1946 80 90 100 110...

Page 3: ...2...

Page 11: ...10...

Page 33: ...NOTES 32...

Page 91: ...NOTES 90...

Page 111: ...NOTES 110...

Page 131: ...NOTES 130...

Page 147: ...Fuse panel B P18N083 ELECTRICAL INSTALLATION 146...

Page 163: ...NOTES 162...

Page 181: ...NOTES 180...

Page 187: ...NOTES 186...

Page 203: ...NOTES 202...

Page 208: ...207...