BNP-160 TUMBLE BASKET BLAST CABINET

Page 9

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 25993 Rev B 05/18

The following are examples of the door slide setting

during factory tests:

1) #13 glass beads – slotted door shut

2) #8 glass beads – slotted door open about 3/16"

3) #11 glass beads – slotted door open about 3/32"

4) 180 mesh aluminum oxide – slotted door open

about 3/32"

5) 80 mesh aluminum oxide – slotted door open about

1/8"

4.6.4 To Remove Less Fines:

(Too much good

media carried over to the dust collector.) Loosen the

wing nuts and raise the door by no more than 1/16"

increments.

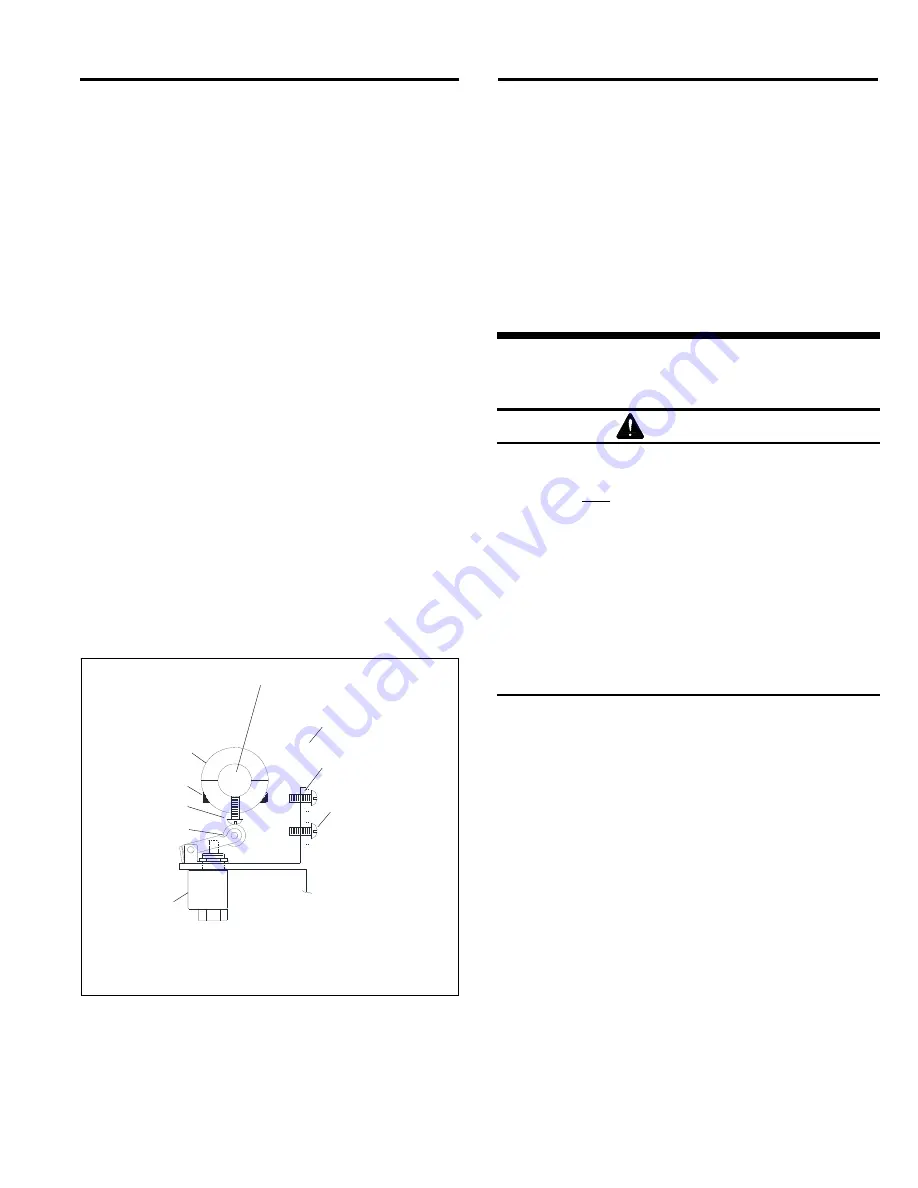

4.7

Dust Collector Pulse,

Pulse Valve/Cam Follower

‒

Figure 10

4.7.1

The pulse activating mechanism is located

within the motor mount bracket.

4.7.2

The dust collector pulses once with each

revolution of the basket. When the screw on the split

collar rotates over the cam follower, it pushes in the

plunger on the 3-way pulse valve and triggers the pulse.

4.7.3

Loosen the collar setscrews and rotate the split

collar so the cam screw is riding on the cam follower.

Tighten the setscrews to secure the collar.

Some items are removed for clarity.

Figure

10

4.7.4

Loosen the mounting bracket screws and adjust

the height so the cam follower depresses the plunger on

the 3-way pulse valve. Snug the screws to hold the

bracket in place.

4.7.5

Set the blast-pressure regulator to zero psi and

set the pulse-pressure regulator to 40 psi.

4.7.6

Turn the timer dial to start the basket rotation.

4.7.7

The collector should pulse each time the cam

screw rides onto the cam follower and stop when the

screw rides off the follower.

4.7.8

Adjust the mounting bracket up or down until the

pulse functions accordingly. Tighten the mounting

screws to secure.

5.0 PREVENTIVE

MAINTENANCE

WARNING

This machine is not to be used for applications

that generate dust from lead coatings, heavy

metals, or any other toxic materials. Failure to

wear approved respirators and eye protection

when servicing dust-laden areas of the cabinet

and dust collector, and when emptying the

container, can result in serious eye irritation and

lung disease. Toxicity and health risk vary with

type of media and dust generated by blasting.

The respirator must be approved for the type of

dust generated. Identify all material being

removed by blasting and obtain a safety data

sheet (SDS) for the blast media.

To avoid unscheduled downtime, establish a weekly

inspection schedule. Inspect all parts subjected to media

contact, including; nozzle, media hose, flex hose, wear

plate, and all items covered in this section.

5.1 Daily

Maintenance

5.1.1

Check media level and condition of media: Refill

or change media as necessary.

5.1.2

Check reclaimer screen for debris: The screen is

accessible through the reclaimer door. With the

exhauster OFF, remove the screen and empty it daily

and when loading media. Empty the screen more often if

part blasted causes excessive debris. Do not operate the

machine without the screen in place, oversized

byproduct from blasting could plug the nozzle.

5.1.3

Drain compressed air filter

‒

Figure 11: The

cabinet is equipped with a manual-drain air filter. Open

the drain at least daily; if water is present, open

periodically during operation. Moist air inhibits the flow of

media; if the filter does not remove enough moisture to

Screws

Setscrews

Mounting Bracket

Motor Mount

(Shown for reference.)

Basket Drive Shaft

(Shown for reference.)

Split Collar

3-Way

Pulse Valve

Cam Screw

Cam Follower