12 - EN

EN - 13

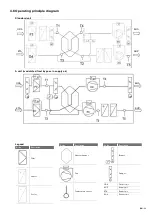

5.3 Condensation drain

Plate exchanger

The plate exchanger is placed in a drip tray which

is fitted with a membrane siphon as standard. The

membrane siphon connects to a plastic 32mm drain

through which condensation can be drained directly.

The condensation drain must have a free outlet to

the siphon of the domestic waste-water system.

Cooling battery

Each cooling battery is placed in a drip tray fitted

with a 32mm plastic drain. In order to prevent

external air leakage, a membrane siphon must be

connected to this plastic drain on site.

Use a siphon with water lock if the cooler is installed

behind the fan (overpressure).

Use a membrane siphon if the cooler is installed

in front of the fan (underpressure). The membrane

siphon does not lock the output pipe with a water

lock, but with a self-locking valve.

135?

Take account of the following factors when fitting the

condensation drain:

�

Spray or blow the membrane siphon before first

use to loosen the non-return valve;

�

The membrane siphon must be mounted at an

angle of 45°;

�

When determining the height of the water lock

(siphon with water lock), take into account not

only the total pressure in the casing, but also

pressure surges that may occur when the valves

are opened and closed, for example. The supplied

overpressure siphon is suitable for overpressures

of up to 600Pa in the cooling section;

�

The siphon with water lock must be fitted with a

sealable filler opening and drain option;

�

One siphon is fitted for each drain;

�

The siphon with water lock must first be filled with

water when (re)starting the unit after a long period

of inactivity;

�

The siphon must be connected air-tight to the

condensation drain of the unit;

�

The siphon may not be connected directly to the

domestic waste-water system. The siphon must

have a free outlet to the siphon of the domestic

waste-water system;

�

The condensation must be drained off frost-free.

5.4 Siphon heating

Siphons are sensitive to frost. A siphon heater

reduces the risk of frost damage. A siphon heater

is a heating spiral that can be wrapped around the

siphon. In order to maximize heating efficiency, the

heating spiral is insulated on the outside.

A present siphon heater must be connected to his

own relay output on the I/O PCB. The connected

relay can be controlled by the standard temperature

sensor T1 of the unit or by a separate temperature

sensor installed near the siphon.

When using a separate temperature sensor the

temperature sensor must be connected to one of the

spare temperature inputs (NTC6 located on the main

PCB or NTC7 located on the I/O PCB)

The separate temperature sensor of the siphon

heating can only be connected to NTC6 or NTC7.

Summary of Contents for ComfoAir 1500

Page 1: ...ComfoAir XL ComfoAir Eco Manual Cooling Fresh Air Clean Air Heating...

Page 45: ...EN 45...

Page 46: ...46 EN...

Page 47: ...EN 47...