835966-UIM-E-0814

Johnson Controls Unitary Products

21

SECTION VIII: SYSTEM START-UP

ENERGIZE CRANKCASE HEATER

In order to energize the crankcase heater, set the indoor cooling ther-

mostat to the OFF position. Close the line power disconnect to the unit.

WITH POWER TO UNIT AND THERMOSTAT IN COOLING

POSITION:

1. In the cooling cycle, discharge gas is pumped to the outdoor coil

which is the condenser. The indoor coil is the evaporator.

2. If fan switch is in ON position, a circuit is made through blower relay

to provide continuous blower operation.

3. With fan switch in AUTO position, a circuit is made from thermostat

cooling contact through blower relay to provide blower operation.

4. System will cycle with thermostat demand to provide cooling as

needed.

SECTION IX: SYSTEM OPERATION

For more information on the control operation, refer to the “OPERA-

TION INSTRUCTIONS - DEMAND DEFROST CONTROL BOARD”

publication.

REQUIRED CONTROL SETUP

1. Consult system wiring diagram to determine proper thermostat wir-

ing for your system.

2. If hot heat pump configuration is desired, change HOT HEAT PUMP

jumper to ON position. This setting MUST be set on the defrost

board.

3. If installation includes a fossil fuel furnace, change FUEL jumper to

ON position. This setting MUST be set on the defrost board.

4. Set low temperature cutout (LTCO), balance point (BP), switch point

(SP), and Y2 Lock jumpers as desired. These settings may be mod-

ified by communicating thermostat.

5. Verify proper system functionality. Confirm room thermostat opera-

tion including fault code display capability.

6. Upon completion of installation, verify that no fault codes are stored

in memory. Clear the fault code memory if necessary.

DEFROST OPERATION

The following defrost curve selection jumper positions are set from fac-

tory.

NOTE:

For information on the 5 & 6 pins, refer to the “Operation Instructions -

Demand Defrost Control Board” publication.

An attempt to start the compressor without at least 8 hours of crank-

case heat will damage the compressor.

The following steps must be taken at the time of installation to insure

proper system operation.

TABLE 3:

Defrost Initiate Curves

Defrost Curve Selection

Jumper Position

PIN 1

PIN 2

PIN 3

PIN 4

16 SEER

Heat Pump Model

2-Ton

2.5-Ton

3-Ton

3.5-Ton

5-Ton

4-Ton

–

–

18 SEER

Heat Pump Model

2-Ton

4-Ton

5-Ton

3-Ton

–

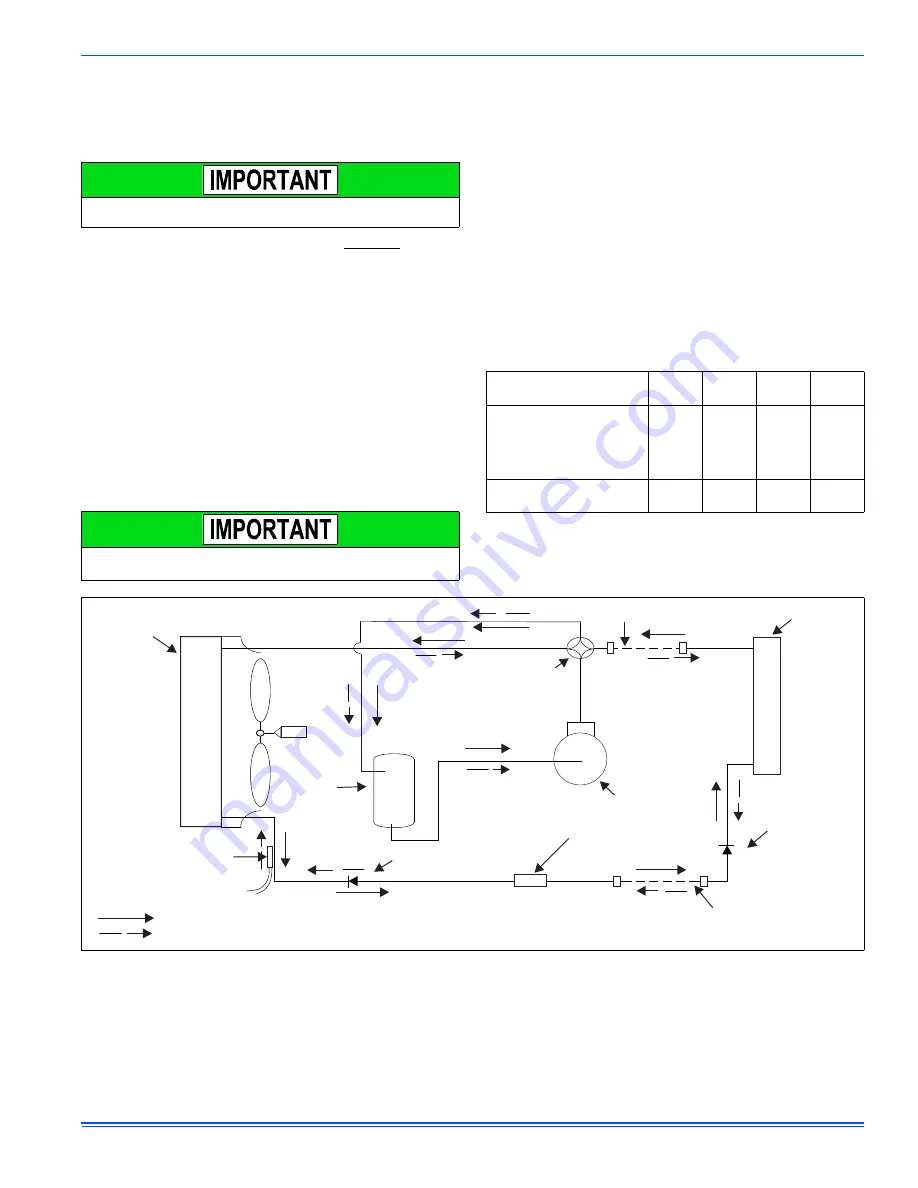

FIGURE 21:

Heat Pump Flow Diagram

.

FLOW RATER

(Cooling)

COOLING CYCLE FLOW

HEATING CYCLE FLOW

INDOOR COIL

4-WAY

REVERSING

VALVE

SUCTION

ACCUMULATOR

COMPRESSOR

OUTDOOR

COIL

FIELD CONNECTED LINE

FILTER DRYER

(Solid core)

LIQUID

SENSOR

FIELD CONNECTED LINE

FLOW RATER

(Heating)

A019-001