JOHNSON CONTROLS

159

SECTION 8 – TROUBLESHOOTING

FORM 155.30-ICOM2.EN.UL

ISSUE DATE: 12/21/2018

8

TROUBLESHOOTING PERFORMANCE

ISSUES

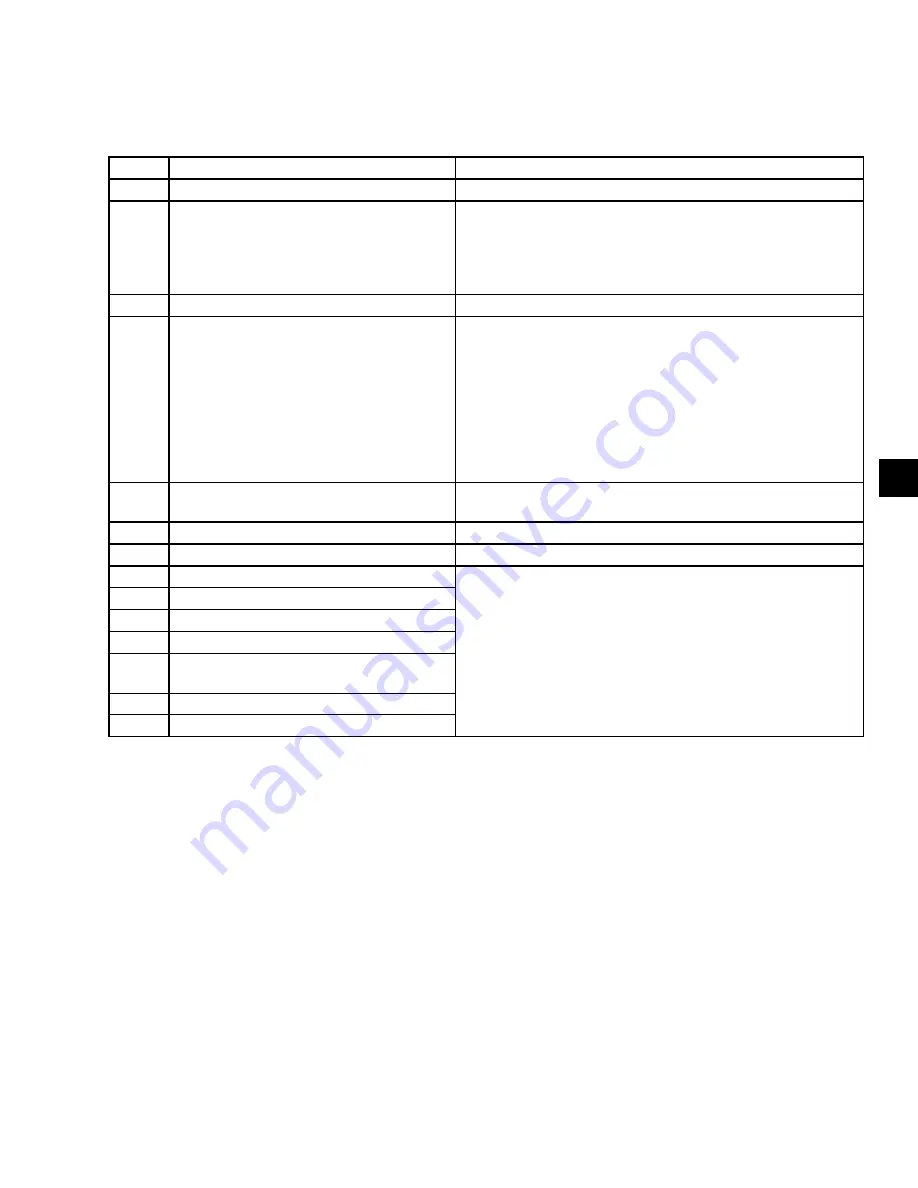

TABLE 44 -

TROUBLESHOOTING PERFORMANCE

ISSUES

ITEM

CAUSE

COUNTERMEASURE

1

Cooling water temperature is high.

Check the capacity of the cooling tower.

2

Cooling water is insufficient.

• See if the cooling water supply rate matches the specification.

•

Check the flow meter, discharge pressure of the cooling water

pump, current, and so on.

•

If the flow rate is insufficient, check the opening ratio of the flow

controller valve and check the strainer for clogging.

3

Cooling water heat exchange tube is dirty.

Contact your local Johnson Controls Service Office.

4

Non-condensable gas remains in machine.

• See

• Check the capacity of the vacuum pump.

• Check the purge unit for trouble.

•

Purge air from the absorption chiller. If partial-load operation is

continued for a long period, non-condensable gas tends to stay

in the absorber. In this case, purge directly from the low-pressure

side (absorber). See

automatic purge unit is installed, purge from the lower pressure

side (absorber) manually.

5

Chilled water outlet temperature controller is

not set properly.

Check that the chilled water outlet temperature controller on the

control panel by the machine is set to the target value.

6

Manual refrigerant blow valves are kept open. Check that manual refrigerant blow valve V8 is closed.

7

Refrigerant pump

Stop

button is pressed.

Press the Refrigerant Pump

Auto

button.

8

Corrosion inhibitor is depleted.

Contact your local Johnson Controls Service Office.

9

Surface active agent is depleted.

10

Refrigerant is dirty (contains solution).

11

Internal cycle control valve is not set properly.

12

Chilled water outlet temperature controller is

broken.

13

Solution is crystallized.

14

Air leaks in absorption chiller.

If the performance is insufficient while the hot water

control valve is fully opened or if the hot water control

valve does not fully open while the load is sufficient,

check numbers 1-7 in the above table in order. If the

cause of the trouble is other than numbers 1-7, it may

be one of number 8-14. In this case, contact your local

Johnson Controls Service Center immediately.