FORM 201.24-NM2

75

YORK INTERNATIONAL

The microprocessor discharge pres-

sure cutout is backed-up by the me-

chanical high pressure cutout located

in each refrigerant circuit.

High Discharge Pressure Unload Point:

The discharge pressure unload point is used to avoid a

high pressure cutout shutdown by unloading a com-

pressor, if its discharge pressure approaches the cutout

value. The chiller can then continue to run automati-

cally at reduced capacity until the cause of the exces-

sive pressure is resolved (e.g. dirty condenser coils) or

cleared (e.g. high ambient temperature).

For the first 60 seconds of operation, discharge pres-

sure limiting is disabled. After this time, if discharge

pressure exceeds the programmed limit, a 1 second

unload pulse will be sent to the slide valve of the af-

fected compressor every 5 seconds until the discharge

pressure drops below the programmed limit.

Reloading will take place when discharge pressure has

dropped 4 bar below the programmed threshold.

Typically the unload point should be set 1.2 to 2 bar

below the discharge pressure cutout setting. The mi-

croprocessor will accept a range of programmable val-

ues between 13.8 and 27.52 bar.

Low Suction Pressure Cutout:

The low suction pressure cutout protects the evapora-

tor from damage due to ice build up caused by opera-

tion at low refrigerant suction pressure.

After the compressor starts, and the pump down cycle

is completed (pump down to cutout or 30 seconds,

whichever comes first), suction pressure is monitored

as long as the compressor runs. For the first 270 sec-

onds of running, suction pressure can be lower than

the programmed cutout, but must be greater than:

PROGRAMMED

X

RUN TIME / 3 +10

CUTOUT

100

For example, if the programmed cutout = 3 bar and

the run time = 60 seconds

This cutout value increases with time, until after 270

seconds, it equals the programmed cutout value. If suc-

tion pressure falls below the calculated cutout value

before 270 seconds, the system will be shutdown.

After 270 seconds, a transient timer system prevents

short term fluctuations in suction pressure from caus-

ing shutdown as follows: If suction pressure drops be-

low the cutout point, a 90 second transient timer starts.

During the 90 second time period, the suction pressure

must be greater than:

This cutout value increases with time, until after 90

seconds, it equals the programmed cutout value. If the

suction pressure rises to more than 0.3 bar above the

programmed cutout value during the 90 second time

period, the timer will be reset.

If the suction pressure does not rise to more than 0.3

bar above the cutout, the timer will remain at zero and

if the pressure then falls below the cutout again, the

system will shutdown on a low pressure fault.

If the Dip Switch (S1) on the AMB board is set for

‘WATER’ cooling mode, the cutout is programmable

between 3.03 and 4.83 bar. In this mode, a setting of

3.03 bar is recommended.

If the Dip Switch (S1) on the AMB board is set for

‘GLYCOL’ (Brine) cooling mode, the cutout is pro-

grammable between 0.34 and 4.83 bar. In this mode,

the cutout should be set to the saturated refrigerant pres-

sure equivalent to 10°C below the temperature of the

chilled liquid.

High Ambient Temperature Cutout:

The high ambient temperature cutout is used to select

the ambient temperature above which the chiller may

D I S C H A R G E

P R E S S U R E

U N L O A D

=

3 6 0 . 0

P S I G

S U C T I O N

P R E S S U R E

C U T O U T

=

3 . 0

B A R G

NEW CUTOUT = 3 x

100 - 60

=

1.2 bar

100

For example, if the programmed cutout = 3 bar and

the timer has run 30 seconds

PROGRAMMED

X

100 - TRANSIENT TIME REMAINING

CUTOUT

100

H I G H

A M B I E N T

T E M P

C U T O U T

=

5 4 . 0 ° C

NEW CUTOUT = 3 x

60/3 + 10

=

0.9 bar

100

7

Summary of Contents for YCWS0313SC

Page 12: ...YORK INTERNATIONAL 12 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT...

Page 36: ...YORK INTERNATIONAL 36 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT Commissioning...

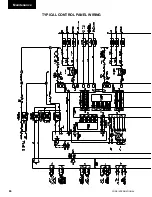

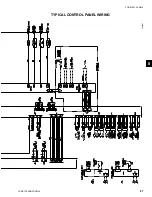

Page 86: ...YORK INTERNATIONAL 86 TYPICAL CONTROL PANEL WIRING Maintenance...

Page 87: ...FORM 201 24 NM2 87 YORK INTERNATIONAL TYPICAL CONTROL PANEL WIRING LD06957 8...

Page 103: ...FORM 201 24 NM2 103 YORK INTERNATIONAL NOTES 11...