FORM 201.24-NM2

33

YORK INTERNATIONAL

COMMISSIONING

Preparation

Commissioning of this unit should only

be carried out by YORK Authorized

personnel.

The Microprocessor Based Control System (MBCS)

Operating Instructions must be read in conjunction

with this section.

The unit ‘ON/OFF’ toggle switch on the front of the

control panel has been set to the ‘OFF’ position at the

factory. This switch must remain in the ‘OFF’ posi-

tion, preventing running of the unit until commissioned

by YORK Authorized personnel. If the switch has been

set to the ‘ON’ position before commissioning then it

must be reported to YORK otherwise the warranty may

be invalidated.

Preparation – Power Off

The following checks should be made with the cus-

tomer supply/supplies to the unit switched off.

Inspection: Inspect unit for installation damage. If

found take action and/or repair as appropriate.

Refrigerant charge: Units are normally shipped as

standard with a full refrigerant operating charge. Check

that refrigerant pressure is present in both systems and

that no leaks are apparent. If no pressure is present a

leak test must be undertaken, the leak(s) located and

repaired. Repaired systems and units supplied with a

nitrogen holding charge must be evacuated with a suit-

able vacuum pump/recovery unit as appropriate to be-

low 100 microns.

Charging from the liquid connection

is necessary on R-22 to ensure the cor-

rect refrigerant mix is maintained.

Do not charge liquid refrigerant with static water in

the cooler. Care must also be taken to charge liquid

refrigerant slowly to avoid excessive thermal stress at

the charging point. Once the vacuum is broken, charge

into the condenser with the full operating charge as

given in Section 9.

Valves: Open the compressor suction and discharge and

liquid line service valves on both systems.

Compressor oil: The compressor oil level must be

between the two sight glasses on the oil separators.

Isolation/protection: Verify that all sources of electri-

cal supply to the unit are taken from point(s) of isola-

tion.

Control panel: Check the panel to see that it is free of

foreign materials (wire, metal chips, etc.) and clean out

if required.

Power connections: Check the customer power cables

are connected correctly. Ensure that connections of

power cables within the panels to the circuit breakers,

terminal blocks or switch disconnectors are tight.

Earthing: Verify that the units protective terminal(s)

are properly connected to a suitable earthing point. En-

sure that all unit internal earth connections are tight.

Compressor Motor Protector Module (-FMP) Cur-

rent Overloads: Check the factory setting of the cur-

rent overload trip value for each compressor motor:

Supply voltage: Verify that the site voltage supply cor-

responds to the unit requirement and is within the lim-

its given in Section 9.

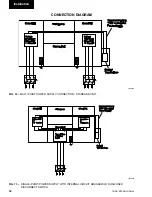

SECTION 5

COMMISSIONING

REFRIGERANT

BREAK VACUUM

RAISE SYSTEM

FROM BOTTLE

PRESSURE TO

CONNECTION FOR:

APPROXIMATELY:

R-22

LIQUID

4.6 BARG (70 PSIG)

YCWS

SYSTEM

107% FLA

AMP SET

SYS X

SYS X MP

DIP SWITCH SETTINGS ON

MOTOR

INPUT

-FMP LEFT = 1

RIGHT = 0

CURRENT VOLTAGE

1

6

3

1

8

4

2

1

= 100%

= 125%

2

4

2

6

FLA

FLA

8

0313 1 & 2

081

1.29

87

50

0

0

1

1

0

0

0

0

0373

1

081

1.29

87

50

0

0

1

1

0

0

1

0

2

103

1.64

110

64

0

1

0

0

0

0

0

0

0423 1 & 2

103

1.64

110

64

0

1

0

0

0

0

0

0

0503

1

103

1.64

110

61

0

0

1

1

1

1

0

1

2

130

2.07

139

81

0

0

1

1

1

1

0

1

0563 1 & 2

130

2.07

139

81

0

0

1

1

1

1

0

0

0613

1

130

2.07

139

81

0

0

1

1

1

1

0

1

2

155

2.47

166

96

0

1

1

0

0

0

0

0

0663 1 & 2

155

2.47

166

96

0

1

1

0

0

0

0

0

5

Summary of Contents for YCWS0313SC

Page 12: ...YORK INTERNATIONAL 12 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT...

Page 36: ...YORK INTERNATIONAL 36 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT Commissioning...

Page 86: ...YORK INTERNATIONAL 86 TYPICAL CONTROL PANEL WIRING Maintenance...

Page 87: ...FORM 201 24 NM2 87 YORK INTERNATIONAL TYPICAL CONTROL PANEL WIRING LD06957 8...

Page 103: ...FORM 201 24 NM2 103 YORK INTERNATIONAL NOTES 11...