FORM 160.54-PW7

9

YORK INTERNATIONAL

REMOTE CURRENT LIMIT SETPOINT with 0-10VDC,

2-10 VDC, 0-20mA, 4-20mA or Pulse Width Modula-

tion Signal.

The Remote Current Limit setpoint can be reset over

the range of 100% to 30% Full Load Amps (FLA) by

supplying (by others) a 0-10VDC, 2-10VDC, 0-20mA,

4-20mA or 1 to 11 second Pulse Width Modulated

(PWM) signal to the OptiView Control Center. The

OptiView Control Center must be configured appropri-

ately to accept the desired signal type as follows:

• The appropriate Remote Mode must be selected:

Analog Remote Mode must be selected when us-

ing a voltage or current signal input. Digital Re-

mote Mode must be selected when using a PWM

input.

• If Analog Remote Mode is selected, the Remote

Analog Input Range setpoint must be set to “0-

10VDC” or “2-10VDC” as detailed below, regard-

less of whether the signal is a voltage or current

input signal type.

• Microboard Program Jumper P23 must be positioned

appropriately per the input signal type as detailed

below. It is recommended that a qualified Service

Technician position this jumper.

Important! The signal type used for

Remote Current Limit Setpoint reset

and the signal type used for Remote

Leaving Chilled Liquid Temperature

setpoint reset must be the same. For

example, if a 0-10VDC signal is be-

ing used for Remote Leaving Chilled

Liquid Temperature Reset , then a 0-

10VDC signal must be used for Re-

mote Current Limit Reset.

0-10VDC - As shown in Fig. 15, connect input to

Microboard J22-1 (signal) and J22-5 (Gnd). The setpoint

varies linearly from 100% to 30% FLA as the input var-

ies from 0-10VDC. This input will only be accepted when

Analog Remote Mode is selected, the “Remote Ana-

log Input Range” setpoint is set for 0-10 Volts, and

Microboard Program Jumper JP23 has been removed.

Calculate the setpoint for various inputs as follows:

SETPOINT (%) = 100 – (VDC X 7)

For example, if the input is 5VDC, the setpoint would

be set to 65% as follows:

SETPOINT (%) = 100 – (5 X 7) = 100 – 35 = 65%

2-10VDC - As shown in Fig. 15, connect input to

Microboard J22-1 (signal) and J22-5 (Gnd). The setpoint

varies linearly from 100% to 30% FLA as the input

varies from 2 to 10VDC. This input will only be ac-

cepted when “Analog” Remote Mode is selected, the

“Remote Analog Input Range” setpoint is set for

“2-10 Volts” and Microboard Program Jumper JP23 has

been removed. Calculate the setpoint for various inputs

as follows:

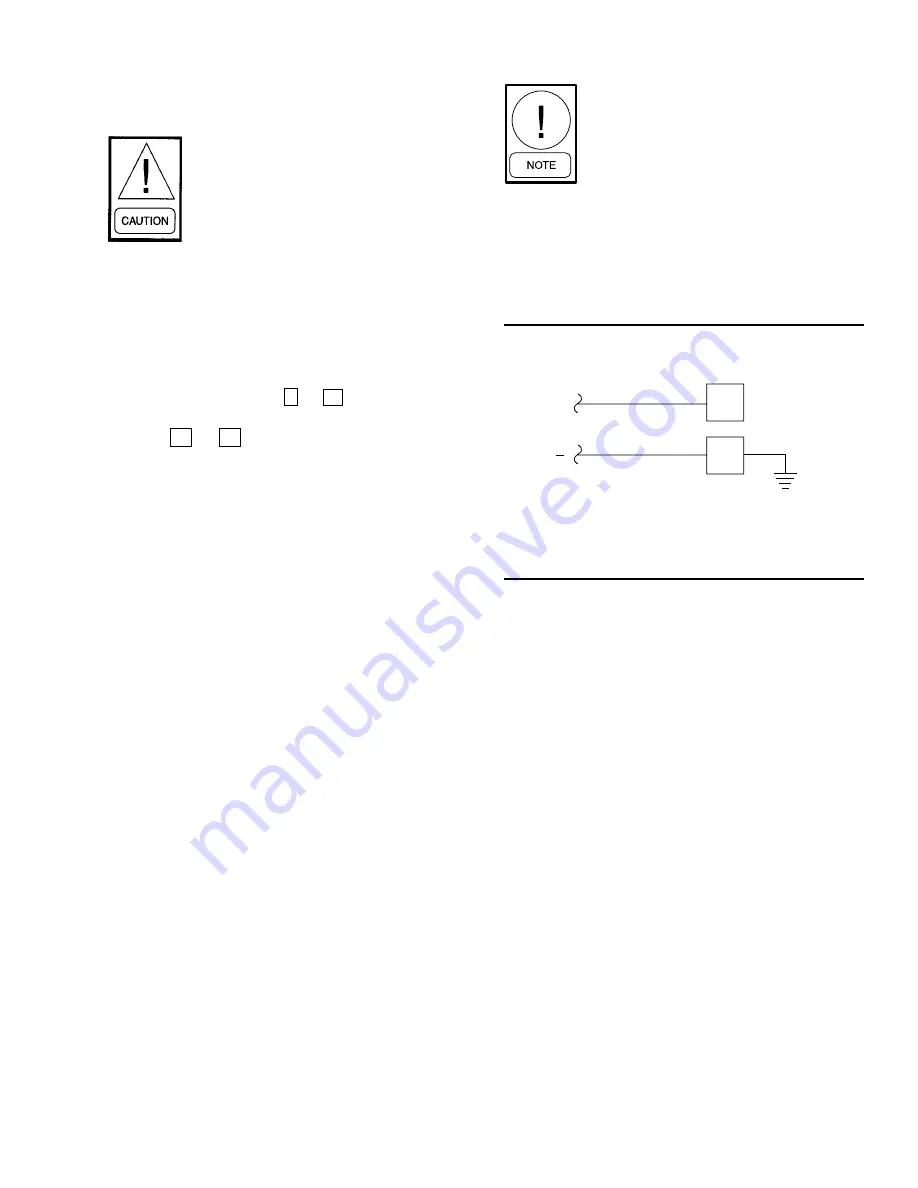

FIG. 14 – ELECTRO-MECHANICAL STARTER

MANUAL RESET OVERLOADS

The chiller compressor type deter-

mines which terminals must be used

for this feature. Failure to use the

proper terminals could result in se-

rious chiller damage!

Terminals are available for connection of the manual re-

set overloads and/or safety devices in the high voltage

Electro-Mechanical Starter for U.L. or C.S.A. approved

units having 2300 to 4160 volt motors. The appropriate

terminals must be selected based on the chiller compres-

sor type. For chillers that are not equipped with compres-

sor code “P”, use terminals 1 and 53 as shown in Figure

14. For chillers equipped with compressor code “P”, use

terminals 15 and 53 as shown in Figure 14A. Refer to

appropriate Remote Motor Starter Specification as fol-

lows: 160.45-PA5.1 (all compressors except “P”);

160.54-PW14 (chillers equipped with “P” compressors).

An opening of the contacts causes the OptiView Control

Center to display: “CYCLING SHUTDOWN – AUTO

RESTART” and “MOTOR CONTROLLER – CON-

TACTS OPEN”. To restart the chiller, reset the external

device in the Electro-mechanical Starter that caused the

shutdown. Then the unit will automatically restart.

FIG. 15 – REMOTE CURRENT LIMIT SETPOINT WITH

0-10VDC OR 2-10VDC SIGNAL

SIGNAL

COMMON

5

1

+

J22

LD04498