ELECTRICAL CONNECTIONS

1. Check the electrical supply to be sure that it meets the

values specified on the unit nameplate and wiring label.

2. Route low voltage wiring into bottom of control box as

shown in Figure 8. Make low voltage wiring connections

inside the junction box.

3. The complete connection diagram and schematic wiring

label is located on the inside surface of the unit electrical

box cover. Field wiring is also shown previous page.

4. All field wiring to be in accordance with national electrical

codes.

NOTE: Power wiring, disconnect switch, and overcurrent pro-

tection to be supplied by installer. See Physical and

Electric Data Table for proper sizes. Use COPPER

CONDUCTORS ONLY.

WARNING: Unit must be grounded with a separate ground

conductor wire.

5. Install the proper size weatherproof disconnect switch out-

doors and within sight of the unit.

6. Run power wiring from the disconnect switch to the unit.

7. Install the proper size time-delay fuses or circuit

breaker,and make the power supply connections.

8. Energize the crankcase heater to save time by preheating

the compressor oil while the remaining installation is com-

pleted.

CRANKCASE HEAT

The crankcase heater is energized whenever the compressor

is not running. Check for proper operation by feeling for heat

on the compressor where the heater is installed. The heater

should be energized for at least 8 hours before the thermostat

is set to operate the compressor.

CAUTION: An attempt to start the compressor without at least

8 hours of crankcase heat will damage the com-

pressor.

A warning label with an adhesive back is supplied in the unit

installation instruction packet. This label should be attached to

the field supplied disconnect switch where it will be easily seen.

See below:

SYSTEM PRESSURE REFERENCE

The “system pressure reference charts” (See Figures 11 and

12) should only be used as a quick check of system perform-

ance. It should not be used to determine proper system charge.

1. Operate the unit for a minimum of 15 minutes before

checking system.

2. Measure Pressure at the suction and liquid fitting and

measure the Outdoor Ambient Temperature.

3. Enter the chart at the measured Suction Pressure and

Outdoor Ambient Temperature to determine the expected

Liquid Pressure.

Actual liquid pressure should agree with valves shown plus or

minus 5 psig.

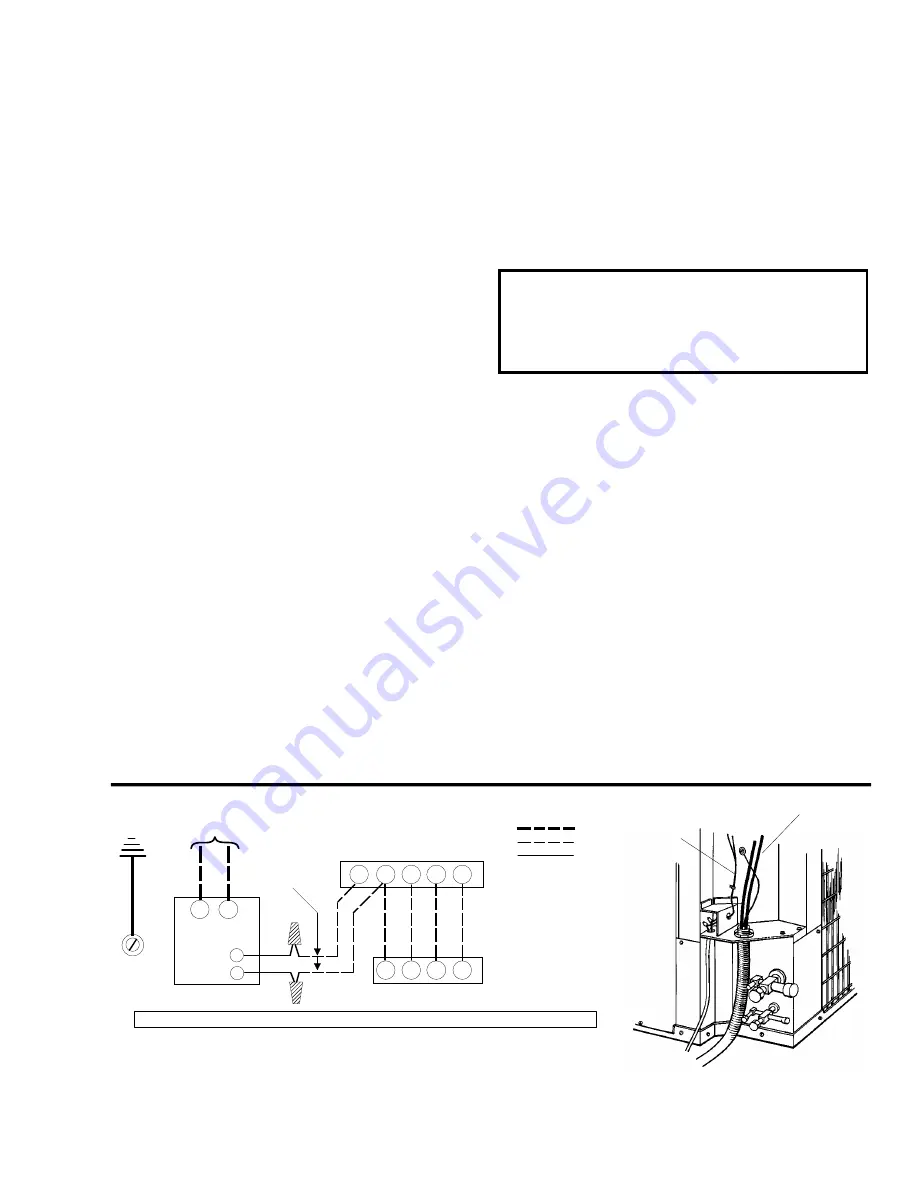

POWER

WIRING

CONTROL

WIRING

FIGURE 8 - TYPICAL FIELD WIRING

C

Y

R

G

W

W

G

R

Y

CONTACTOR

TERMINALS

24 VOLT

CONTROL

WIRING

FURNACE OR AIR HANDLER

TERMINAL BLOCK

POWER

CONTROL

FACTORY

ROOM THERMOSTAT

*

* Terminal W is only required on

systems with heat.

POWER WIRING

208/230-1-60

COIL

GROUND

SCREW

ALL FIELD WIRING TO BE IN ACCORDANCE WITH NATIONAL ELECTRICAL CODE (NEC) AND/OR LOCAL CODES

ALL OUTDOOR WIRING MUST BE WEATHERPROOF. USE COPPER CONDUCTORS ONLY.

IF POWER HAS BEEN OFF FOR 8 HOURS OR LONGER,

DISCONNECT SWITCH MUST BE TURNED ON 8 HOURS

BEFORE THERMOSTAT IS SET TO “HEAT”,"COOL" OR

“AUTO”

035-03095.

IMPORTANT

550.36-N2Y

Unitary Products Group

9