YASKAWA

TOEPC71061782C GA800 Drive Installation & Primary Operation

99

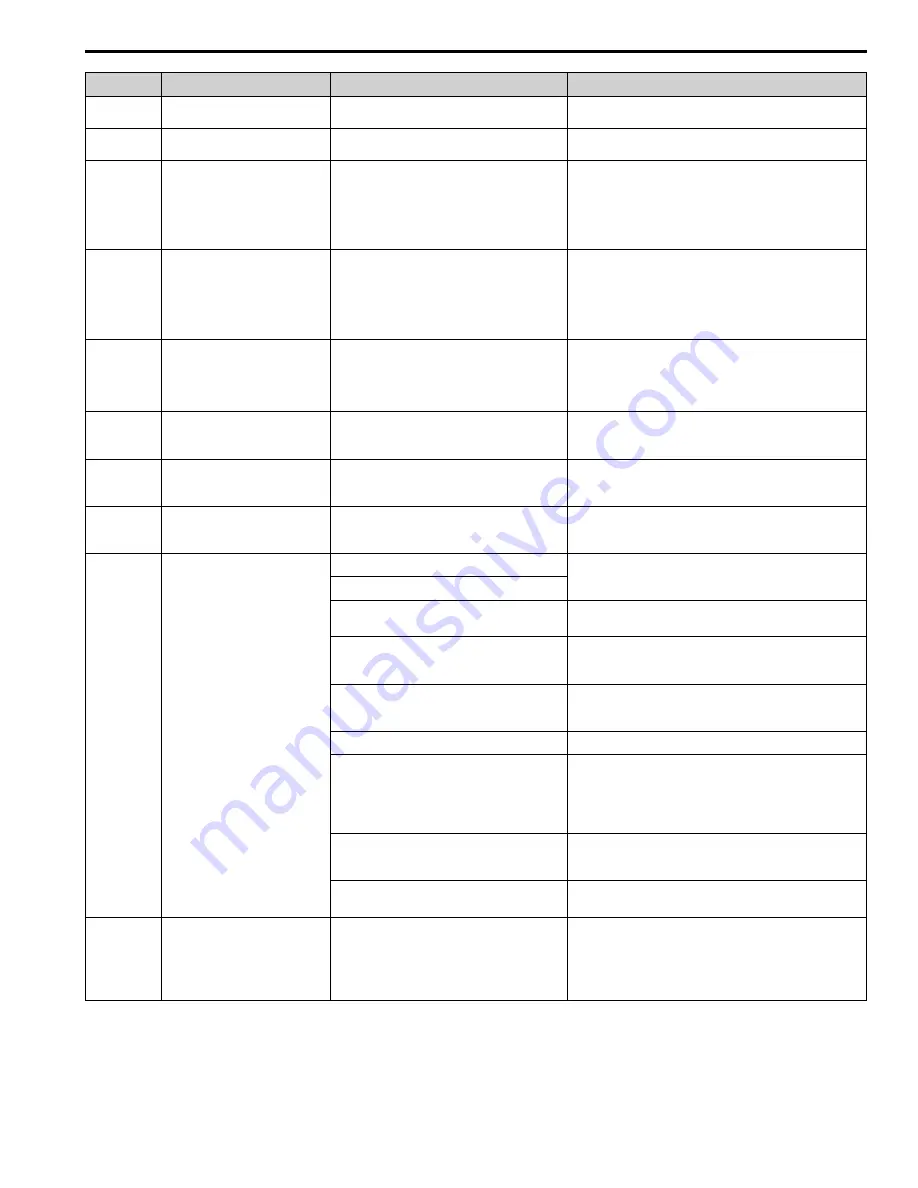

Code

Name

Causes

Possible Solutions

The drive could not complete tuning for leakage

inductance in fewer than 300 seconds.

Examine and repair motor wiring.

Er-14

Motor Speed Error 2

The motor speed was more than two times the

amplitude of speed reference during Inertia Tuning.

Decrease the value set in

C5-01 [ASR Proportional Gain 1]

.

Er-15

Torque Saturation Error

During Inertia Tuning, the output torque was more

than the value set in

L7-01 to L7-04 [Torque Limit]

.

•

Increase the value set in

L7-01 to L7-04 [Torque Limit]

as much

as possible.

•

Decrease the values set for the frequency and amplitude of the

test signals used when doing inertia tuning. First, decrease the

test signal amplitude, and then do Inertia Tuning. If the error

continues, decrease the test signal frequency and do Inertia

Tuning again.

Er-16

Inertia ID Error

The inertia found by the drive was too small or too

large during Inertia Tuning (10% or less, or 50000%

or more).

•

Decrease the values set for the frequency and amplitude of the

test signals used when doing inertia tuning. First, decrease the

test signal amplitude, and then do Inertia Tuning. If the error

continues, decrease the test signal frequency and do Inertia

Tuning again

•

Correctly set the motor inertia as specified by the motor, and do

Inertia Tuning again.

Er-17

Reverse Prohibited Error

b1-04 = 1 [Reverse Operation Selection = Reverse

Disabled]

Note:

You cannot do Inertia Tuning if the drive cannot

rotate the motor in reverse.

1.

Enable reverse in the target machine.

2.

Set

b1-04 = 0 [Reverse Enabled]

.

3.

Do Inertia Tuning again.

Er-18

Back EMF Error

The result of the induced voltage tuning was not in

the applicable range.

1.

Make sure that the input motor nameplate data is correct.

2.

Do Auto-Tuning again and correctly set the motor nameplate

data.

Er-19

PM Inductance Error

The Auto-Tuning results of the PM motor inductance

were not in the applicable range.

1.

Make sure that the input motor nameplate data is correct.

2.

Do Auto-Tuning again and correctly set the motor nameplate

data.

Er-20

Stator Resistance Error

The Auto-Tuning results of the PM Motor Stator

Resistance were not in the applicable range.

1.

Make sure that the input motor nameplate data is correct.

2.

Do Auto-Tuning again and correctly set the motor nameplate

data.

Er-21

Z Pulse Correction Error

The motor is wired incorrectly.

The encoder is wired incorrectly.

1.

Repair motor and encoder wiring errors.

2.

Do Z Pulse Offset Tuning again.

You did Auto-Tuning on a coasting motor.

1.

Wait for the motor to fully stop.

2.

Do Z Pulse Offset Tuning again.

The setting for the direction of the encoder motor

rotation is incorrect.

1.

Set the direction of motor rotation of the encoder in

F1-05

[Encoder 1 Rotation Selection]

correctly.

2.

Do Z Pulse Offset Tuning again.

The number of encoder pulses is incorrect.

1.

Set the number of encoder pulses in

F1-01 [Encoder 1 Pulse

Count (PPR)]

correctly.

2.

Do Z Pulse Offset Tuning again.

The motor Inertia is too large.

Increase the value set in

n8-02 [Pole Alignment Current Level]

.

Parameter

b1-04 = 1 [Reverse Operation Selection =

Reverse Disabled]

and you did Z Pulse Offset

Tuning.

•

If the machine prevents reverse rotation, disconnect the motor

from the machinery, set

b1-04 = 0 [Reverse Enabled]

, then do Z

Pulse Offset Tuning. When tuning is complete, set

b1-04 = 1

[Reverse Disabled]

.

•

If the machine does not prevent reverse rotation, set

b1-04 = 0

and do Z Pulse Offset Tuning.

The motor vibrates during tuning.

•

Increase the values set in

n8-03 [Pole Position Detection Time]

and

n8-04 [Pole Alignment Time]

.

•

Decrease the value set in

n8-02 [Pole Alignment Current Level]

.

The encoder is damaged.

•

Examine the signal output from the encoder.

•

Replace the encoder.

Er-25

HighFreq Inject Param Tuning Err

The motor data is incorrect.

Do Stationary Auto-Tuning again.

Note:

If the drive detects

Er-25

after doing Stationary Auto-Tuning,

the motor may not be able to use high frequency injection

control. Contact Yaskawa or your nearest sales representative

for more information.