32

YASKAWA ELECTRIC

TOBP C730600 83C YASKAWA AC Drive Option SI-C3 Installation Manual

6 Related Drive Parameters

6

Related Drive Parameters

The parameters in

Table 7

set the drive for operation with the option. Confirm proper setting

of all parameters in

Table 7

before starting network communications. Refer to the manual

packaged with the drive for details on setting parameters.

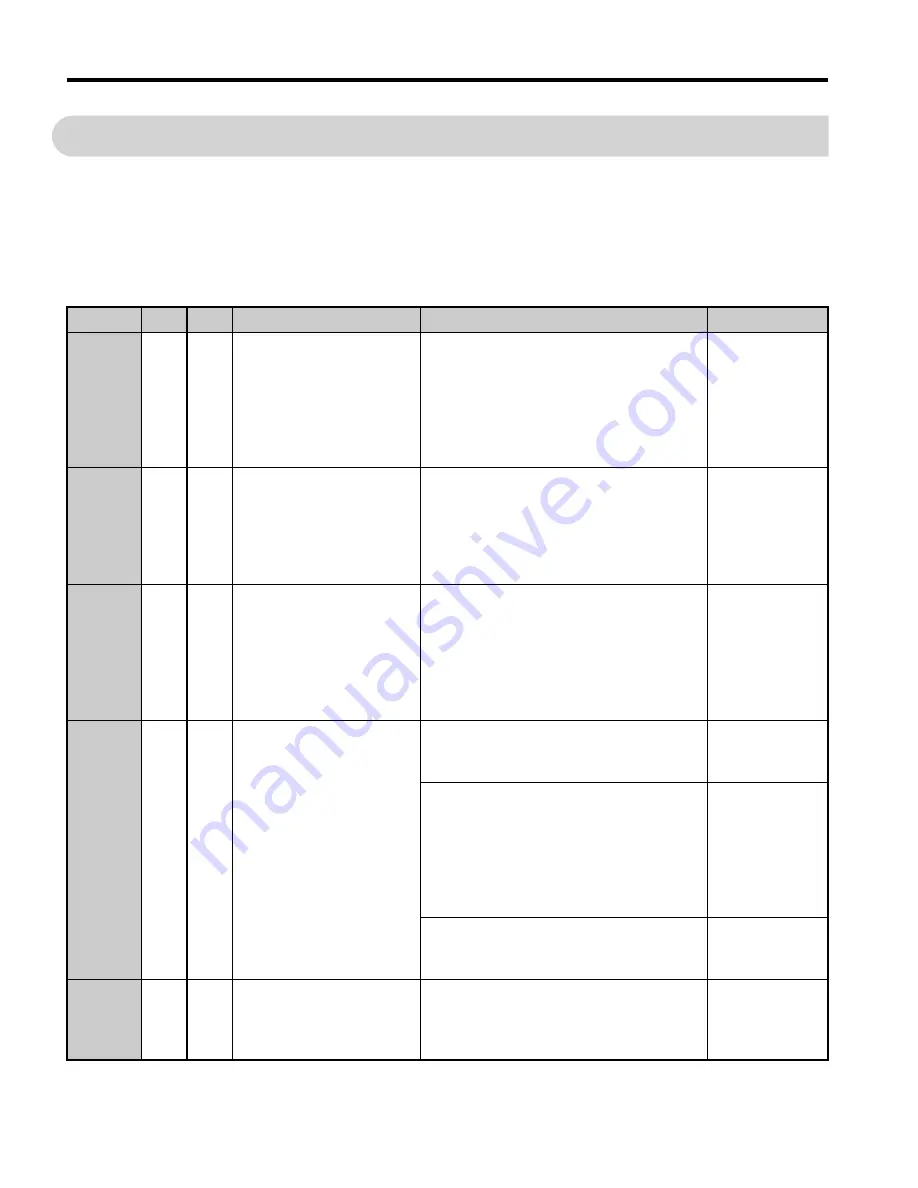

Table 7 Parameter Settings

O: Applicable, –: Not applicable, INV: Drive, CNV: Energy-Saving Unit

No.

INV CNV

Name

Description

Values

b1-01

<1>

–

Reference 1 Source

Selects the input method for frequency

reference.

0: Keypad

1: Analog Input

2: Memobus/Modbus Communications

3: Option PCB

4: Pulse Train Input

Default: 1

Range: 0 to 4

b1-02

<1>

Run Command 1 Source

Selects the input method for the Run

command.

0: Keypad

1: Digital Input

2: Memobus/Modbus Communications

3: Option PCB

Default: 1

Range: 0 to 3

b1-18

<2>

–

Voltage Reference Source

Selects the voltage reference input source.

0: Digital Operator - RUN and STOP keys

1: Analog input

2: MEMOBUS/Modbus communications

3: Option PCB

7: Input voltage based control 1

8: Input voltage based control 2

Default: 8

Range: 0 to 3, 7,

8

F6-01

<3>

Communications Error

Selection

Selects drive response when a bUS error is

detected during communications with the

option.

–

When installed to drives:

0: Ramp to stop.

1: Coast to stop.

2: Fast Stop (Use C1-09)

3: Alarm only.

<3>

4: Alarm - Run at d1-04

<3> <4>

5: Alarm - Ramp to Stop

<4>

Default: 1

Range: 0 to 5

<5>

When installed to energy-saving units:

1: Stop

3: Alarm Only

Default: 1

Range: 1, 3

F6-02

Comm External Fault

(EF0) Detect

Selects the condition for external fault

detection (EF0).

0: Always detected.

1: Detection during run only

Default: 0

Range: 0, 1

TOBP_C730600_83C_3_0_E.fm 32 ページ 2018年10月24日 水曜日 午後5時59分