ELECTRICAL COMPONENTS

8-108

EAS27990

CHECKING THE BULBS AND BULB SOCK-

ETS

TIP

Do not check any of the lights that use LEDs.

Check each bulb and bulb socket for damage

or wear, proper connections, and also for conti-

nuity between the terminals.

Damage/wear

→

Repair or replace the bulb,

bulb socket or both.

Improperly connected

→

Properly connect.

No continuity

→

Repair or replace the bulb,

bulb socket or both.

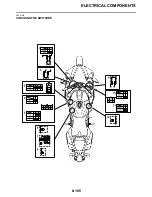

Types of bulbs

The bulbs used on this vehicle are shown in

the illustration.

• Bulbs “a” are used for the headlights and

usually use a bulb holder that must be

detached before removing the bulb.

• Bulbs “b” and “c” are used for front turn sig-

nal/position lights and rear turn signal lights.

They can be removed from the socket by

pushing and turning the bulb counterclock-

wise.

• Bulbs “d” are used for auxiliary and license

plate lights and can be removed from their

respective socket by carefully pulling them

out.

Checking the condition of the bulbs

The following procedure applies to all of the

bulbs.

1. Remove:

• Bulb

WARNING

EWA13320

Since the headlight bulb gets extremely

hot, keep flammable products and your

hands away from the bulb until it has

cooled down.

ECA14380

• Be sure to hold the socket firmly when

removing the bulb. Never pull the lead,

otherwise it may be pulled out of the ter-

minal in the coupler.

• Avoid touching the glass part of the head-

light bulb to keep it free from oil, other-

wise the transparency of the glass, the

life of the bulb, and the luminous flux will

be adversely affected. If the headlight

bulb gets soiled, thoroughly it with a cloth

moistened with alcohol or lacquer thin-

ner.

2. Check:

• Bulb (for continuity)

(with the pocket tester)

No continuity

→

Replace.

TIP

Before checking for continuity, set the pocket

tester to “0” and to the “

Ω

×

1” range.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the positive tester probe to termi-

nal “1” and the negative tester probe to ter-

minal “2”, and check the continuity.

b. If reading indicate no continuity, replace the

bulb.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Checking the condition of the bulb sockets

The following procedure applies to all of the

bulb sockets.

1. Check:

• Bulb socket (for continuity)

(with the pocket tester)

No continuity

→

Replace.

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Summary of Contents for YZFR1Y(C) 2009

Page 1: ...SERVICE MANUAL YZFR1Y C 14B 28197 10 LIT 11616 22 78 2009 ...

Page 6: ......

Page 8: ......

Page 36: ...SPECIAL TOOLS 1 27 ...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29 EAS20410 LUBRICATION DIAGRAMS ...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 31 ...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 33 ...

Page 72: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 35 ...

Page 73: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 36 1 Main axle 2 Oil water pump assembly ...

Page 74: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 37 ...

Page 75: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 38 1 Main axle 2 Oil delivery pipe 2 3 Drive axle ...

Page 76: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 39 ...

Page 78: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 41 ...

Page 80: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 43 ...

Page 81: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 44 1 Balancer shaft 2 Crankshaft ...

Page 82: ...COOLING SYSTEM DIAGRAMS 2 45 EAS20420 COOLING SYSTEM DIAGRAMS ...

Page 84: ...COOLING SYSTEM DIAGRAMS 2 47 ...

Page 85: ...COOLING SYSTEM DIAGRAMS 2 48 1 Radiator cap 2 Radiator 3 Radiator fan 4 Oil cooler ...

Page 86: ...CABLE ROUTING 2 49 EAS20430 CABLE ROUTING ...

Page 88: ...CABLE ROUTING 2 51 ...

Page 90: ...CABLE ROUTING 2 53 ...

Page 92: ...CABLE ROUTING 2 55 ...

Page 94: ...CABLE ROUTING 2 57 ...

Page 96: ...CABLE ROUTING 2 59 ...

Page 98: ...CABLE ROUTING 2 61 ...

Page 100: ...CABLE ROUTING 2 63 ...

Page 102: ...CABLE ROUTING 2 65 ...

Page 104: ...CABLE ROUTING 2 67 ...

Page 106: ...CABLE ROUTING 2 69 ...

Page 108: ...CABLE ROUTING 2 71 ...

Page 110: ...CABLE ROUTING 2 73 ...

Page 113: ......

Page 148: ...PERIODIC MAINTENANCE 3 35 ...

Page 253: ...ENGINE REMOVAL 5 12 Installed depth of gasket c 3 5 mm 0 14 in ...

Page 286: ...PICKUP ROTOR 5 45 Yamaha bond No 1215 Three Bond No 1215 90890 85505 ...

Page 291: ...ELECTRIC STARTER 5 50 ...

Page 340: ...TRANSMISSION 5 99 ...

Page 356: ...WATER PUMP 6 15 ...

Page 378: ...AIR INDUCTION SYSTEM 7 21 EAS27040 AIR INDUCTION SYSTEM ...

Page 384: ...AIR INDUCTION SYSTEM 7 27 ...

Page 387: ......

Page 388: ...IGNITION SYSTEM 8 1 EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 394: ...ELECTRIC STARTING SYSTEM 8 7 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 400: ...CHARGING SYSTEM 8 13 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 403: ...CHARGING SYSTEM 8 16 ...

Page 404: ...LIGHTING SYSTEM 8 17 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 408: ...SIGNALING SYSTEM 8 21 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 415: ...SIGNALING SYSTEM 8 28 ...

Page 416: ...COOLING SYSTEM 8 29 EAS27300 COOLING SYSTEM EAS27310 CIRCUIT DIAGRAM ...

Page 419: ...COOLING SYSTEM 8 32 ...

Page 420: ...FUEL INJECTION SYSTEM 8 33 EAS27330 FUEL INJECTION SYSTEM EAS27340 CIRCUIT DIAGRAM ...

Page 484: ...FUEL PUMP SYSTEM 8 97 EAS27550 FUEL PUMP SYSTEM EAS27560 CIRCUIT DIAGRAM ...

Page 488: ...ELECTRICAL COMPONENTS 8 101 EAS27972 ELECTRICAL COMPONENTS ...

Page 490: ...ELECTRICAL COMPONENTS 8 103 ...

Page 492: ...ELECTRICAL COMPONENTS 8 105 EAS27980 CHECKING THE SWITCHES ...

Page 516: ...ELECTRICAL COMPONENTS 8 129 ...

Page 523: ......

Page 524: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...

Page 525: ...WIRING DIAGRAM YZFR1Y C ...

Page 526: ...WIRING DIAGRAM YZFR1Y C ...