• DO NOT use any damaged or repaired wheel parts.

• Make sure that all parts of the wheel are the correct

parts for that wheel assembly.

• DO NOT mix parts between different types or manu-

facturers of wheels.

• DO NOT mix types of tires, type of tire tread, or wheel

assemblies of different manufacturers on any one lift

truck.

Do not use a steel hammer on the wheel. Use a rubber,

lead, plastic, or brass hammer to put parts together.

Make sure that the side ring is in the correct position.

The ends of the side ring must not touch. The clearance

at the ends of the side ring will be approximately 13 to

25 mm (0.5 to 1.0 in.) after it is installed. If the clearance

is wrong, the wrong part has been used.

1.

Clean and inspect all parts of the wheel. Paint any parts

that have rust or corrosion.

2.

Install a new inner tube in the tire. Used tubes and flaps

can cause tire failure.

WARNING

Do not lubricate the tire bead with antifreeze or petro-

leum-based liquid. Vapors from these liquids can cause

an explosion during inflation or use.

3.

Apply a rubber lubricant or a soap solution to the tire bead

and tube.

4.

Install a new tire flap.

WARNING

Do not lubricate the tire bead with antifreeze or petro-

leum-based liquid. Vapors from these liquids can cause

an explosion during inflation or use.

5.

Make sure the rim is the correct size for the tire. Lubricate

the part of the wheel that contacts the bead and flap.

6.

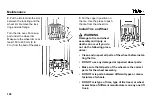

Install the three-piece or four-piece wheel in the tire as

shown in

Tire Installation, Three- or Four-Piece Wheel

.

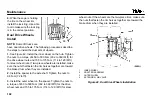

7.

Install the two-piece wheel in the tire as shown in

Tire

Installation, Two-Piece Wheel

.

Maintenance

178

Summary of Contents for GDP040-070VX

Page 81: ...Figure 12 Seat Adjustment Full Suspension Operating Procedures 79 ...

Page 113: ...Figure 17 Kubota 2 5L LPG Engine Maintenance and Lubrication Points Maintenance Schedule 111 ...

Page 169: ...Figure 37 LPG Tank and Bracket Maintenance 167 ...

Page 203: ...Spacer 5 15 4 15 2 15 1 15 11 14 ...