-11-

F.

G.

H.

I.

C.

D.

E.

Tips for Printout Scaling(

①

):

If you find the dimension of the printout doesn't

match the 3D model, you may adjust the scale of the

X/Y axis. The setting will be stored in the software

and applied to every print job sent afterwards.

④

④

②

①

③

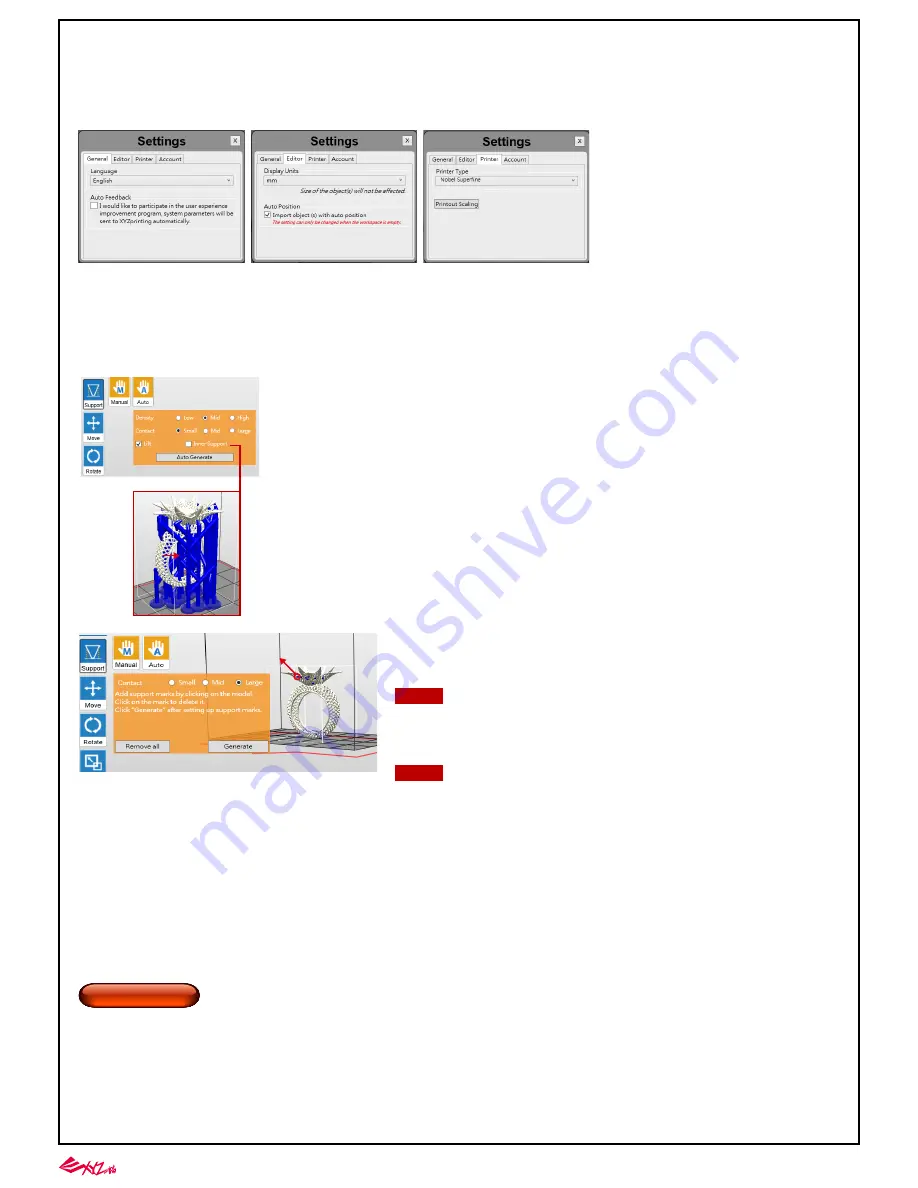

Operation Flow

①

②

③

Click "Import" to import a .stl/.3ws/.3wn file to the virtual platform.

Adjust the placement, angle and size of the object with "Move", "Rotate" and "Scale" buttons on the left as desired. Also add supports and brim for objects with

overhangings or that have less contact with the platform.

Click "print" and setup printing preference based on the features of the prints, and click "Print" to slice and send the file for printing.

You may generate support automatically with XYZware_Nobel, and then add/delete the

support structure based on your printing experience. Use both functions help to ensure the success

of printing, and may decrease resin consumption and shorten printing time.

Once the support structures are setup, you can save the object in

.3ws

format. With this file format,

you can re-adjust the support layout.

If the object is moved vertically or resized, the support structure will be reset. Please set

up the supports again.

J.

K.

L.

M.

N.

O.

Manual editing: you may add or delete support structure based on the features of the print manually.

To add support, simply select a proper size of the contact point and then click on the model at the

overhangs. To delete support, just click on the support mark (the blue dot). After setting up support

marks, click "Generate" to continue.

Move the object: move the object along the x, y, or z axis. You may also press and hold ALT key and drag the mouse to move the object horizontally.

Rotate the object: adjust the angle of the object around the x, y, or z axis. Flipping the object around to adjust the face on the platform may help to enhance printing

performance. Increasing the contact area between the object and the platform may help to enhance printing quality and strength.

Resize the object: Scale the object as you desire. The adjustment to the object on the platform will not affect the size of your original file.

View info of the object: check the dimension and location of the object, so you can tell the size of the object easily.

Remove the object from the platform: select an object and click the option to delete it from the platform. Or you may press Delete key to remove the object.

View printer status.

Support auto generation: XYZware_Nobel is able to analyze the features of the model and add support structure to where

necessary. Simply select a desired density

①

and contact

②

, choose to "Lift"

③

the print and/or print without internal support

④

, and press "Auto Generate" to preview the support structure.

①

Density : Large overhangs will require more support structure. However, more support structure will take longer for printing.

②

Contact : Thicker contact point will lead to higher strength but will take longer for printing.

③

Lift : Lift the objects over the platform will ease the removal after printing. However, the support structure under the prints

will take longer for printing.

④

Inner Support : For objects with inner overhanging structure, XYZware_Nobel will add support to the parts. However the

support inside may not be removed easily, you may consider printing without inner support.

Save as .stl or .3ws file: Save all objects on the platform to a single stl/3ws file. Any adjustment to the size or placement of the objects will apply to the file.

Setup printing preference and send the objects for printing: Once your device is connected to the printer, click "Print" to open printout setting window (options are the

same as "Export" window). Set your printing preference based on the features of the objects and hit "Print" to proceed.

Setup interface language, printer type, display unit and etc.

Info/Software & firmware update: Apply printer firmware and XYZware_Nobel updates when prompt by the software for stable printing performance.

Zoom in/out: Zoom in or out the platform to view the details of objects.

Switch views: Switch views with a click to view objects from different angles.

Support structure: support structure is required under overhangs. It prevents the falling for gravity and the deforming due to the peeling force during printing, and

increases adhesion of the model to the platform.

Note

Tip

Support mark

①