P15

da Vinci Color mini

Function Operation and Instructions

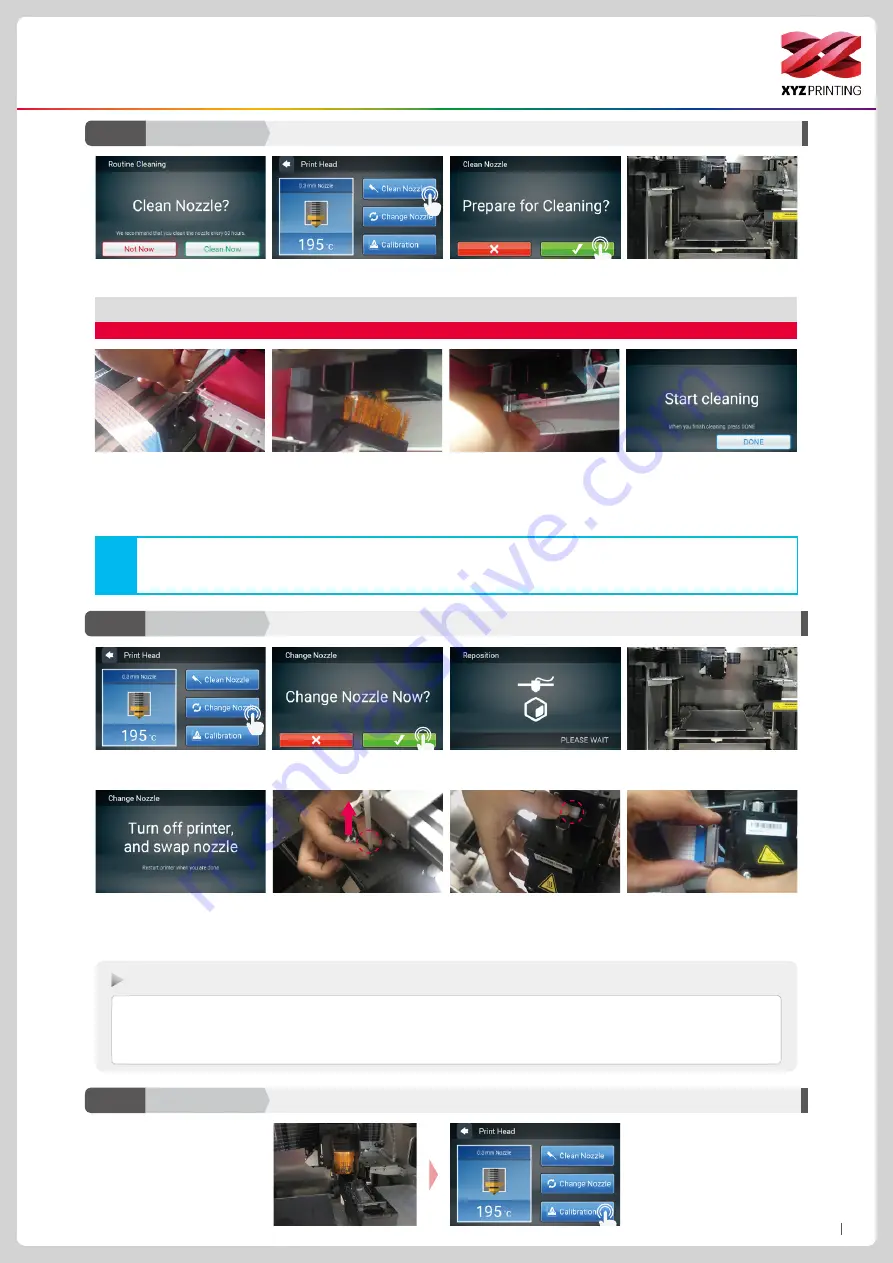

Clean Nozzle

D2-1

Print-Head

Change Nozzle

D2-2

Print-Head

2. Tap Clean Nozzle in the print

head section.

1. Please clean the nozzle after

printing 60 hours.

3. Check if cleaning is necessary. Tap Check to clean it.

Note: do not touch the metal part of the print head as it becomes hot during the operation.

4. Inset the feed hole cleaning wire

into the feed hole and push it down-

wards to drive out the filament from

the print head. (It is recommended

that the operation is performed from

the top of the machine.)

6. Insert the print head cleaning wire

into the nozzle from the bottom to

clean it.

5. Remove the filament residue from

the print head with a wire brush.

7. After the cleaning operation is

completed, tap DONE.

When the temperature of the print head reaches the operating temperature, the cleaning operation will start.

In order to prevent print quality from impact due to residual and accumulated filament, which results in poor discharge, after

long-term use of print nozzle, it is recommended to enable the "CLEAN NOZZLE" (nozzle cleaning) function of the printer every

60 hours of print to clear residuals with nozzle cleaning wire or feeding path cleaning wire. (Filament should be unloaded from

the extruder and remove the guide tube before cleaning the feeding path.)

Note

2. Tap to confirm that you want to

change the nozzle.

6. Change the print head from above

the machine. (If there is a guide tube

installed, please make sure that the

material has been returned and then

removed the guide tube.)

1. Tap Change Nozzle.

3. Wait until the print head moves to

a proper position for change.

7. Press the white release button to

separate the print head.

4. The position of the print head

change is shown above.

5. Turn off the power before chang-

ing the print head.

8. Hold the print head with one hand

and remove the bus with the other.

The removal of the print head is

completed.

Installation sequence of new print head:

1. Connect the bus.

2. Press the white release button on the print head and assemble the print head and the mechanism. After attaching the print head, check to

see that it is secure and does not shake.

3. Turn on and use the printer.

This function can be operated

if the printing device is

colliding with the ink

service station at which will

automatically calibrated to the

correct position.

Calibration

D2-3

Print-Head