16

This section describes proper starting techniques and some troubleshooting information.

STARTING THE ENGINE

Safety Information

Keep loose objects such as shirt sleeves, neckties, and scarves away from the spinning tires, flywheel, and gears. Be careful not to drop utensils such as screwdrivers and

pencils into the spinning tires, flywheel, and gears. If these objects contact moving engine or transmission parts, it may cause mechanical breakage and personal injury.

When you operate an engine, keep children and others away from you and the engine.

Anyone who is not operating the engine must be at least 6 meters away from the engine. If the engine comes off, it may cause injury.

Never operate the engine in an enclosed area such as a basement or a garage. Model engines, like automobiles, emit poisonous exhaust fumes during operation. Only

operate the engines outdoors where there is good ventilation.

Make certain the glowplug clip is not in the way of the spinning tires, flywheel and gears. Damage may be caused if it contacts the spinning tires, flywheel or gears.

Check the throttle linkage connections before starting and running the model truck.

If any connections fail, it may cause personal injury.

We strongly recommend wearing safety eyeglasses or safety shields when you operate an engine.

Model engine fuel is highly flammable and must be handled with the extreme caution. Keep objects that create fire risks (such as cigarettes) away from the engine and fuel

supply system. No-one should be smoking nearby the engine or fuel.

FLAMMABLE

DO NOT TOUCH

PROHIBITION

COMPULSORY

PROHIBITION

PROHIBITION

COMPULSORY

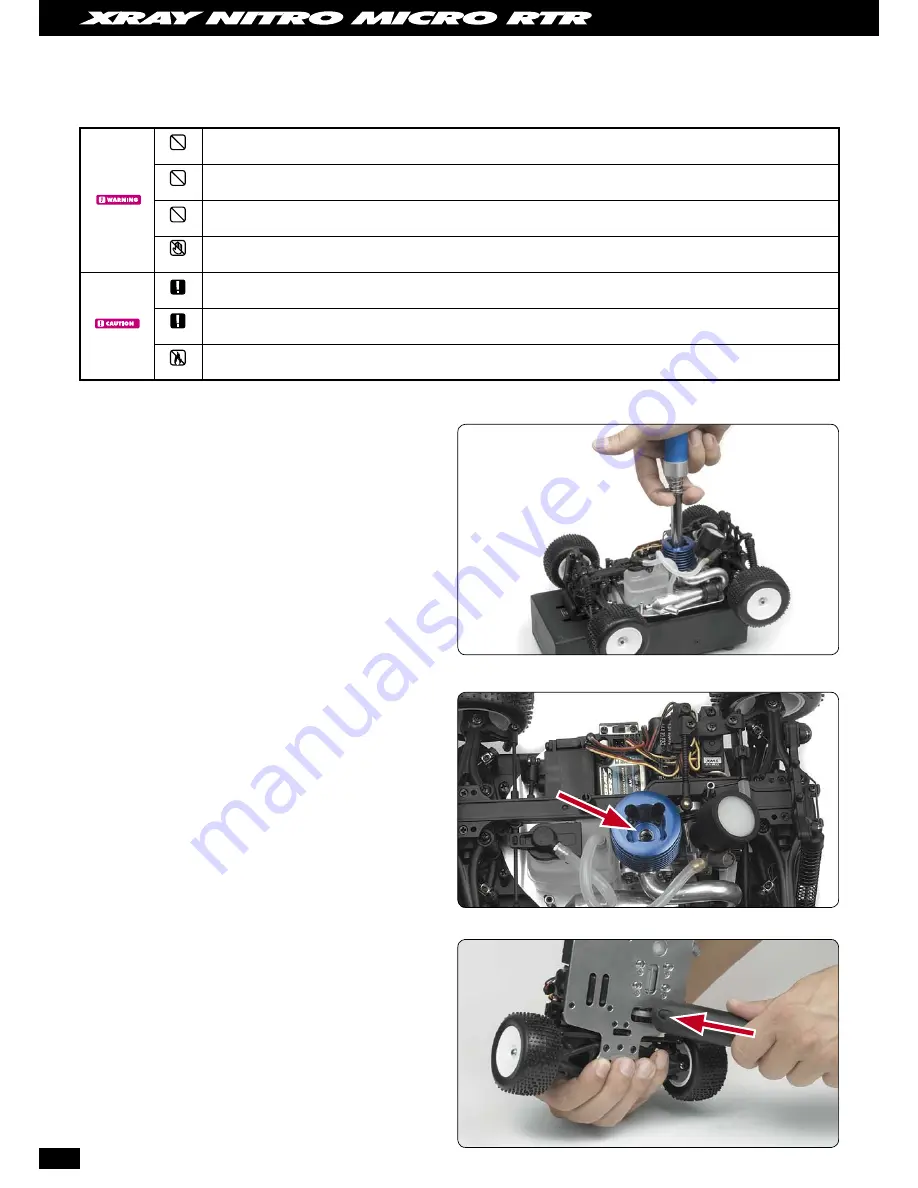

Fill up the fuel tank and "dry-start" the engine for 2-3 seconds without applying the

glowplug starter, and with the carburetor in "idle" position; this primes the fuel lines

and allows the fuel to reach the engine. Then apply the glowplug starter and start the

engine. The engine should fire up immediately.

If the engine does not fire up immediately, check the fuel line to see if fuel is reaching

the carburetor. If fuel is not reaching the carburetor, remove the glowplug starter,

cover the exhaust tailpipe and "dry-start" the engine for 2 seconds. This will build up

extra pressure in the pipe and in the pressure line to the fuel tank, causing the fuel to

be pushed to the carburetor.

Apply the glowplug starter, and start the engine.

Once the engine has started, apply a little throttle and allow the engine to warm up

to operating temperature. This is an important routine that you should always follow.

The internal parts need to receive lubrication and reach operating temperature before

the engine can have a load applied to it.

If your transmitter has throttle servo trim adjustment (a.k.a. "end point adjustment"),

adjust the range of motion of the throttle linkage for full throttle and full brake.

STARTING PROCEDURE

Excess fuel in the cylinder may cause the engine to flood (by extinguishing the

glowplug), or it may cause a hydraulic lockup (when excess fuel fills the cylinder

above the piston, preventing the piston from moving upward). If this happens, DO

NOT try to start the engine, or severe engine damage may result.

1. Remove the glowplug, open the throttle fully, cover the glowplug hole

with a cloth, then turn over the engine. The excess fuel will be ejected through

the glowplug hole.

2. Check the operation of glowplug with the glowplug starter before screwing the

glowplug back in again.

Restart the engine.

FLOODING & HYDRAULIC LOCKUP

To stop the engine safely and quickly, turn the truck over and press a hard plastic part

(for example, the handle of a screwdriver) against the rotating flywheel.

STOPPING THE ENGINE

Summary of Contents for Nitro Micro NT18MT

Page 1: ...M I C R O...