20

DRIVING THE MICRO NITRO TRUCK

After you have broken in and adjusted the engine… and broken in the ball differentials… it’s time to drive your micro nitro truck and have some fun!

Here are some things to keep in mind when driving your micro nitro truck:

• DO NOT run the truck in or through water, snow, or mud. Water and mud drawn through the air filter and will severely damage the engine, and even small amounts of

water can cause electronics failure and loss of control.

• The micro nitro truck engine is a high-performance, powerful engine. Apply throttle gently to prevent flipping or loss of control.

• Avoid over-revving the engine with the wheels off the ground. This “no load” condition may result in internal engine damage.

• Avoid excessive high-speed operation running for long periods of time or long distances. This may exceed the engine’s maximum safe RPM limit.

• Do not drive the truck with any kind of damage, especially drivetrain damage. This may cause engine damage from overloads due to drivetrain drag or friction, or over-

revving due to loose or missing parts.

• Do not use your truck to tow anything behind it. The engine is cooled by airflow over the finned cylinder head when the truck is at speed. Towing puts a high load on the

engine, while at the same time limits engine cooling of the engine due to low speed.

• If your truck gets stuck, stop immediately! Move the truck and then continue driving.

• NEVER turn off the radio system while the engine is running, as this could cause the truck to go out of control.

ADJUSTING THE MICRO NITRO TRUCK

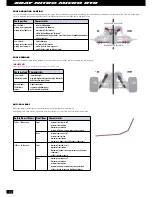

THROTTLE LINKAGE ADJUSMENT

• Turn on the transmitter and receiver and set the throttle servo trim to the neutral position.

• Adjust the idle adjustment screw on the carburetor to open approx. 2mm.

• Adjust both the throttle linkage and brake linkages accordingly.

• DO NOT adjust the linkage with the engine running.

Idling Adjustment Screw.

Use to adjust the idle setting of the carburetor.

Do not allow carburetor to close to less than 1mm.

• Adjust the servo-horn mounting position for the carburetor to open fully.

• Change the pivot mounting position on the servo horn in case the carburetor is not

opening fully or if it is opening excessively. Or if available on the transmitter, adjust the

throttle endpoint.

• Adjust the brake rod collar so the brake works smoothly.

• If the brake applies too much or not enough, adjust the brake rod collar accordingly.

Or if available on the transmitter, adjust the brake endpoint.

• To tighten brake, turn collar to thread brake rod INTO pivot.

• To loosen brake, turn collar to thread brake rod OUT of pivot.

•

NEUTRAL (IDLE)

•

FULL THROTTLE

•

FULL BRAKE

Engine idling 2mm

Engine idling 2mm

CLUTCH ENGAGEMENT

The NT18 engine clutch shoes engage in

higher RPM range. If you prefer an earlier

engagement under lower RPM, deassemble

the clutch bell and slightly bend the clutch

shoes assembly together with the springs.

The springs will become softer and will let the

clutch shoes engage later. It is very important

that you bend both clutch springs equally.

The engine manufacturer advises that due to

the specifications of the micro size nitro engine

and the manufacturing processes, this may

result in some fuel leakage that may be of

a higher rate than larger scale nitro engines.

The amount of fuel leaked may differ from

engine to engine; this is natural and therefore

is not considered as a fault or defect.

ENGINE LEAKAGE

SETTING AN EARLIER CLUTCH

ENGAGEMENT

SPUR

GEAR

PINION

GEAR

FINAL

RATIO

ACCELERATION

SPEED

16

17

18

19

20

21

54

8.44

7.94

7.50

7.11

6.75

6.43

INTERNAL RA

TIO 1:2.5

GEARING

SPUR

GEAR

PINION

GEAR

FINAL

RATIO

ACCELERATION

SPEED

16

17

18

65

10.16

9.56

9.03

INTERNAL RA

TIO 1:2.5

NT18T GEAR RATIO TABLE

NT18MT GEAR RATIO TABLE

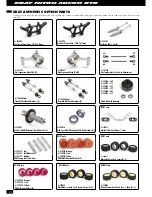

AVAILABLE CLUTCH BELLS

PART NUMBER CLUTCH BELL

NT18T

NT18MT

388516

16 T

x

x

388517

17 T

x

x

388518

18 T

x

x

388519

19 T

x

-

388520

20 T

x

-

388521

21 T

x

-

x fi ts

- does not fi t

Summary of Contents for Nitro Micro NT18MT

Page 1: ...M I C R O...