PH: 866.476.9217

9

VI. PRE-START CHECK LIST

1.

Check FRL Air Control Service Unit: Regulator set at 85-90 PSI; Fill the

Lubricator with the air tool oil supplied. See Section VII: Compressed Air

Treatment for details.

2.

With air pressure OFF, install Capstan Drive Fitting making sure that the Pin

Retainer and O-Ring are properly seated.

3.

Connect all air hoses and make sure all controls are locked and properly

secured.

4.

When using new air hose, blow lubricated air through the hose to completely

coat the inside with oil. This may take up to 10 minutes.

5.

Each day, before opening any car gates, operate the GO-A13-HA, free-

speed, for about 5-minutes. This will allow oil to coat the Impactor's internal

components.

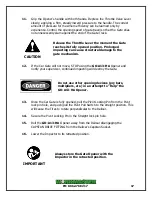

Compressed air is an invisible hazard. Any

component through which it passes is capable

of releasing an explosive force which could

result in personal injury or death. As noted

earlier, all persons involved in the operation

and maintenance of this equipment should be

thoroughly familiar with its use.

Be sure all hose connections are tightly

secured. A loose hose not only causes air leaks,

but can whip around and injure personal in the

area. Secure hose couplings with safety pins,

clips, cables or chains.