PH: 866.476.9217

5

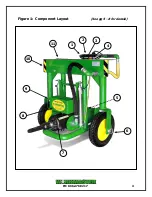

COMPONENT LAYOUT DESCRIPTIONS

(See Figure 1, pg 4)

1.

AIR INLET

The air inlet is a 1" NPT opening with a full-port, Universal (Chicago type)

Coupling. The Coupling supplied is the recommended fitting for the

GO-A13-HA. Replacing the Coupling with a quick-connect type plug will

restrict air flow to the Impactor.

2.

THROTTLE VALVE

The Throttle Valve is a self-closing, lever-operated valve that is attached to

the right hand side of the frame on the Handle Assembly. The Throttle Valve

has a spring loaded lever, which shuts off air to the Impactor as soon as the

throttle is released. Only when the Throttle Lever is depressed will the

Impactor be activated.

3.

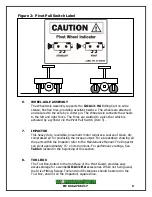

PIVOT PULL SWITCH

The Pivot Pull Switch is a pneumatic actuated valve that controls the

movement of the GO-A13-HA's wheels. When the Switch is in the PIVOT

position, the wheels will rotate so that they are parallel to the railcar. When

the Pull Switch is in the STRAIGHT position, the wheels will move

perpendicular to the railcar. The label located on the Pivot Guard, See

Figure 2, shows the Pull Switch position for the desired wheel movement.

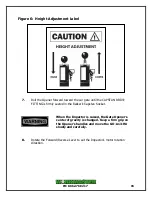

4.

HEIGHT ADJUSTMENT LEVER

The Height Adjustment Lever is a pneumatic valve that controls the

movement of the GO-A13-HA's Impactor. When the Lever is pulled toward

the Operator the Impactor will rise to a max height of 24 inches off the

ground. By pushing the Lever away from the Operator of the Impactor will

lower to a minimum height of 10 inches off the ground. Once the Lever is

released the vertical lift cylinders mounted on either side of the chassis will

hold the Impactor in place to accommodate varying height capstans.

5.

FORWARD/REVERSE LEVER (F/R Lever)

Located in the rear of the Impactor (closest to the operator), the F/R Lever

controls the direction the Impactor will turn.