14

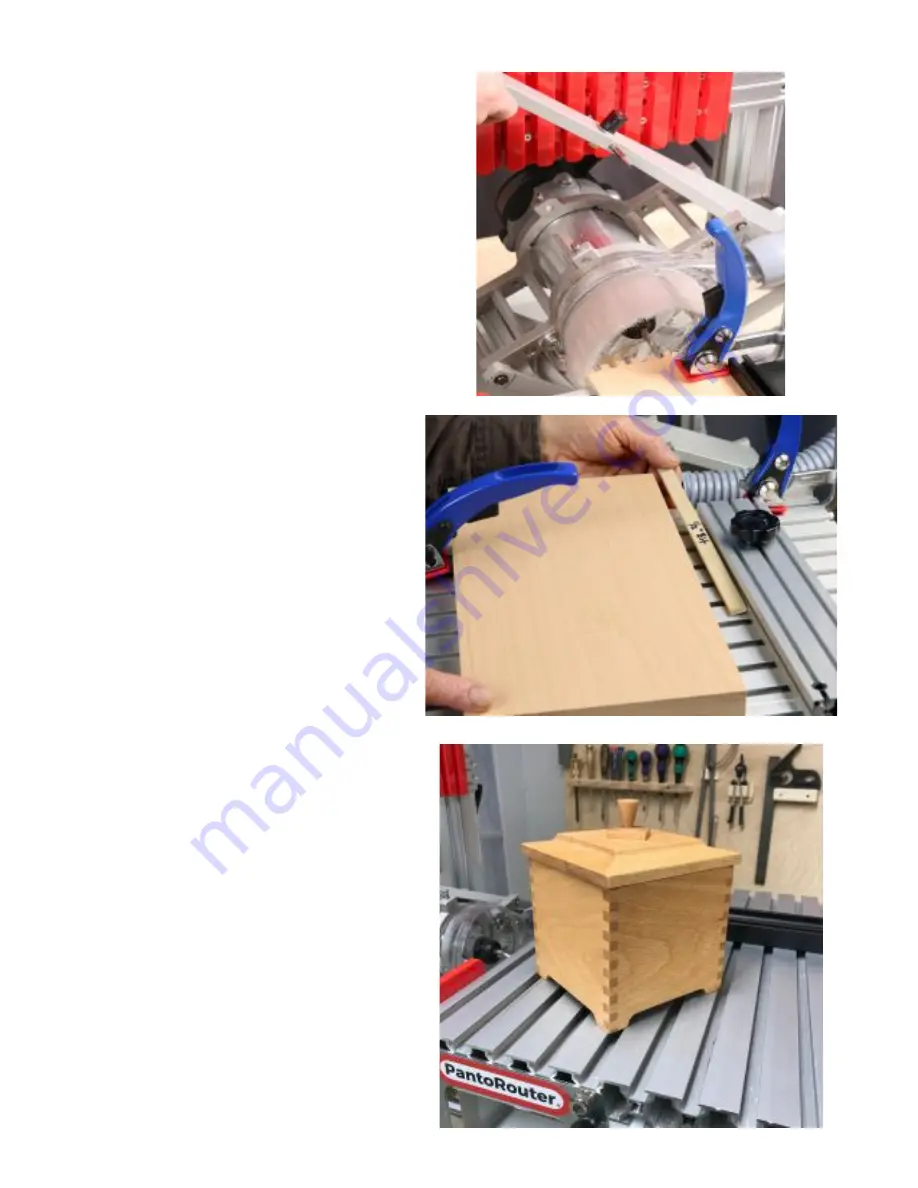

Another dust-free process.

Paired with a pow-

erful vac or dust collector, the

PantoRouter’s dust collection system grabs

every chip.

Measure the bit with dial calipers and rip or

plane a spacer to the exact same width. The

spacer goes between the workpiece and the

fence, offsetting this half of the joint so the

edges of the workpieces will line up.

(The aluminum fence shown to the left is an

older model. The current version is black

and no longer needs the round knob to stay

square.)

Cut with confidence.

Now you can cut stacks

of boards for the other half of the joint, know-

ing the fit will be perfect.