2-9

Installation Information

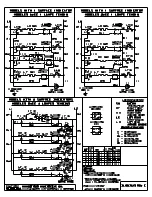

CT Hoods and DD Ventilation

I

SLAND

H

OOD

I

NSTALLATION

S

PECIFICATIONS

AND

P

REPARATION

FOR

M

ODEL

IH4227

A straight, short duct run will allow

1.

the hood to perform more effi ciently.

Limit the number of elbows and tran-

sitions to as few as possible. Long

duct runs, elbows and transitions will

reduce the performance of the hood.

NOTE:

All hoods must exhaust to the

outdoors.

NOTE:

There is a possibility of noise is-

sues, if a short duct run is coupled with a

remote blower.

Always use metal ducting. Do not

2.

use fl ex ducting.

Wolf recommends installing a back-

3.

draft damper in all installations

(included with hood). In cold weather

installations a back-draft damper is

necessary to minimize the back-fl ow

of cold air into the room.

Wolf recommends the hood be in-

4.

stalled 24” (610 mm) to 30” (762 mm)

above the cooking surface.

NOTE:

Local building codes may require

the use of make-up air. Consult a local

HVAC professional for specifi c require-

ments.

E

LECTRICAL

R

EQUIREMENTS

Wolf cooktop wall hoods require a

separate, grounded, 110/120 VAC, 60 Hz

power supply. The service should have its

own 15 amp circuit breaker.

NOTE:

You must follow all National

Electrical Code regulations. In addition,

be aware of local codes and ordinances

when installing your service.

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

C

OOKTOP

I

SLAND

H

OOD

I

NSTALLATION

C

ONSIDERATIONS

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, THIS VENTILATION HOOD SHOULD ONLY BE

INSTALLED WITH BLOWERS MANUFACTURED BY WOLF APPLIANCE INC. AND SPECIFIED FOR USE WITH

THESE VENTILATION MODELS.

Figure 2-15 Island Hood Installation Considerations

Summary of Contents for CT

Page 2: ......

Page 3: ...1 1 General Information CT Hoods and DD Ventilation SECTION 1 GENERAL INFORMATION ...

Page 8: ...1 6 General Information CT Hoods and DD Ventilation NOTES ...

Page 9: ...2 1 Installation Information CT Hoods and DD Ventilation SECTION 2 INSTALLATION INFORMATION ...

Page 35: ...Controls Operation CT Hoods and DD Ventilation 3 1 SECTION 3 CONTROLS OPERATION ...

Page 39: ...Access Removal CT Hoods and DD Ventilation 4 1 SECTION 4 COMPONENT ACCESS REMOVAL ...

Page 54: ...Access Removal CT Hoods and DD Ventilation 4 16 NOTES ...

Page 55: ...5 1 Troubleshooting CT Hoods and DD Ventilation SECTION 5 TROUBLESHOOTING ...

Page 62: ...5 8 Troubleshooting CT Hoods and DD Ventilation NOTES ...

Page 63: ...6 1 Technical Data CT Hoods and DD Ventilation SECTION 6 TECHNICAL DATA ...

Page 66: ...6 4 Technical Data CT Hoods and DD Ventilation NOTES ...

Page 67: ...Wiring Schematics CT Hoods and DD Ventilation 7 1 SECTION 7 WIRING DIAGRAMS SCHEMATICS ...

Page 68: ...Wiring Schematics CT Hoods and DD Ventilation 7 2 MODEL CTWH30 WIRING DIAGRAM ...

Page 69: ...Wiring Schematics CT Hoods and DD Ventilation 7 3 MODEL CTWH36 WIRING DIAGRAM ...

Page 70: ...Wiring Schematics CT Hoods and DD Ventilation 7 4 MODEL IH4227 WIRING DIAGRAM ...

Page 72: ...Wiring Schematics CT Hoods and DD Ventilation 7 6 MODEL DD30 DD36 SCHEMATIC ...

Page 76: ...Wiring Schematics CT Hoods and DD Ventilation 7 10 MODEL DD30 DD36 CONTROL SCHEMATIC ...

Page 77: ...Wiring Schematics CT Hoods and DD Ventilation 7 11 MODEL DD POWER SUPPLY WIRING ...

Page 80: ...Wiring Schematics CT Hoods and DD Ventilation 7 14 BLOWER SCHEMATIC 600 900EXT ...

Page 81: ...Wiring Schematics CT Hoods and DD Ventilation 7 15 BLOWER SCHEMATIC 1200EXT ...

Page 82: ...Wiring Schematics CT Hoods and DD Ventilation 7 16 BLOWER SCHEMATIC 1500EXT ...

Page 83: ...8 1 Parts Exploded CT Hoods and DD Ventilation SECTION 8 PARTS LISTS EXPLODED VIEWS ...

Page 98: ...8 16 Parts Exploded CT Hoods and DD Ventilation NOTES ...