Original operation manual

AIRCOMBI

27

AirCombi_BAoDB_en_1701 • rs

Transport, installation and assembly

Safety measures at the place of installation:

➤

This machine requires a solid base and sufficient free space for safe

operation.

➤

Always keep the working area, especially all walkways and standing

areas, clean and tidy. Immediately remove any spilled material and

cleaning agent.

➤

Always ensure adequate ventilation at the work place to avoid damage

to health and material objects. Always ensure an air change rate of at

least 5.

➤

Always observe the processing instructions issued by the material

manufacturers.

➤

Even though there are no legal directives for low-mist Airless spraying

methods, all hazardous solvent vapours and paint particles should be

extracted.

➤

Protect objects adjacent to the spraying object against possible damage

caused by the material mist.

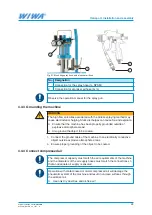

4.3 Assembly

WARNING

If assembly work is carried out by people who have not been trained for

this work, they endanger themselves and other people and impair the

safety and reliability of the machine.

➤

Electrical components must only be mounted by trained qualified elec-

tricians – with all the other components, e.g. the spray hose and the

spray gun being assembled by trained personnel only.

WARNING

Sources of ignition may result from assembly work (e.g. through mechanical

sparks, electrostatic charge, etc.).

➤

Carry out all installation and maintenance work outside of areas with

explosive atmospheres.

➤

Assemble the parts or fittings dismantled for transport purposes before

start up and in compliance with the intended use of the system.

➤

Ensure that the compressed air shut-off valves are closed and all air

pressure regulators have been fully turned down before carrying out any

installation work.