Original operation manual

AIRCOMBI

19

AirCombi_BAoDB_en_1701 • rs

Machine Description

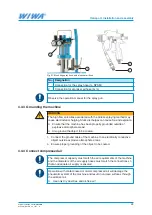

3 Machine Description

The AirCombi devices of

WIWA

are divided into two series which basically

differ in the size of the high pressure pumps.

➤

PROFIT

➤

PHOENIX

Using this method, the spraying material is transferred to the AirCombi spray

gun under moderate pressure and pre-atomized. The very fine spray dis-

tribution is achieved by applying regulated compressed air as the paint is

discharged. A soft, controllable spray jet is produced with minimum paint mist

and rebound.

1

2

3

4

5

6

No. Description

1

AirCombi spraying equipment

2

AirCombi spray gun

3

High pressure filter

4

Atomizer air hose

5

Material hose

6

Container with spraying

material

Fig. 6

: Flow chart for AirCombi operation

The technical data of your machine can be found on the attached machine

card or on the type plate.

3.1 Intended use

The AirCombi devices of

WIWA

are only suitable for spraying of coating and

ancillary materials for surface treatment.

The AirCombi spraying process is ideal for very fine painting tasks covering

large areas and for shaped or small workpieces.

The devices are primarily used in trade workshops such as carpenter's work-

shops for coating wood, but also in the industry for very delicate surfaces.

They are suitable for virtually all sprayable paints and varnishes.

Water-based paints and media that can be thinned with water can only be

processed in devices with rust-proof and acid-resistant finishes.

Any other use is considered to be unintended. If you intend to use the

machine for other purposes or with other materials and thus not for the

purpose for which it is intended, you must ask WIWA for permission –

otherwise the warranty will be invalidated.

Intended use also includes compliance with the technical documentation

and adherence to the prescribed operating, servicing and maintenance

guidelines.