DuoMix Installation Handbook

26

Variable Speed Injection Mixing For

Hydronic Heating Systems*

The purpose of this essay is to explore the

practical application of Variable Speed Injection

Mumping to effect precise heat transfer from high

temperature to low temperature hydronic heating

system loops. Often the available heat source

produces higher temperature water than is required

by the heat delivery system. To effectively achieve

this lower water temperature, the high temperature

water must be injected into the system at a con-

trolled rate to mix with the system return water,

raising the temperature just enough to meet the

heating load. Various devices and plumbing ar-

rangements can be used to accomplish this.

In some instances, a heat source - condensing

or electric boiler, geo-thermal heat pump, etc. - can

be operated at low temperatures and dedicated

solely to operating a low temperature radiant

heating system. In the vast majority of systems,

however, mixing is required because:

• A boiler minimum operating temperature is

required

• High temperature water is required for other

system needs

• Water temperatures vary over a wide range,

i.e. solar heat sources, waste heat utilization,

wood fired boilers, etc.

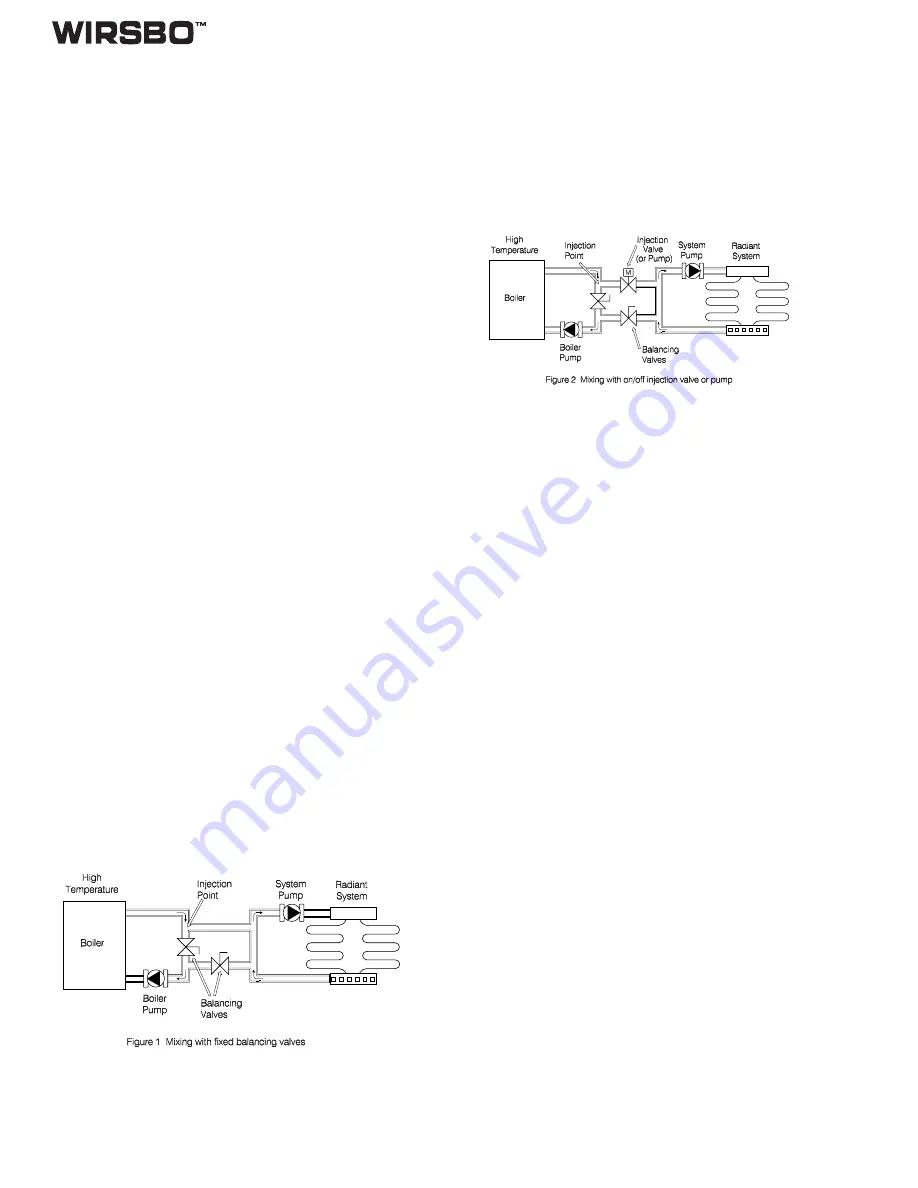

When the water temperatures of both the high

and low temperature loops are constant, with a

constant heating load, a simple manual bypass

balancing arrangement (Figure 1) can be used to

maintain a steady water temperature since it con-

tinually injects high temperature water at a fixed

rate.

*Text and diagrams used with permission from tekmar

When the high temperature supply fluctuates,

and/or varying water temperatures are required in

the heating system at a constant load, an on/off

valve or pump (Figure 2) can be used to intermit-

tently inject hot water at a fixed rate whenever heat

is required.

In most heating systems, the high temperature

supply fluctuates, the system loop temperature

requirements constantly change and the heating

load constantly changes. These factors, combined

with the common need to maintain a safe minimum

boiler return temperature, require that the rate of

heat injection be precisely controlled and con-

stantly readjusted.

The easiest, most reliable and most cost effective

way to accomplish this is to use Variable Speed

Injection Mixing with the Wirsbo DuoMix 201 Sys-

tem Controller.

Variable Speed Injection Mixing (Figure 3) can

be used to transfer heat from a Primary, high

temperature boiler loop to a Secondary, low tem-

perature heating loop. The speed of the Injection

Circulator is automatically adjusted to deliver the

desired volume of hot water to the low temperature

loop. Constant flow can be maintained in both

loops regardless of the circulator speed, and more

or less heat is injected as the circulator speed is

increased or decreased. The circulator speed is

constantly adjusted as the heating system load and

the supply water temperature change. If the boiler

return temperature becomes too cold, the circulator

can be slowed down to reduce the heat injection

rate, resulting in an increased boiler return tem-

perature.

Summary of Contents for DuoMix 201

Page 17: ......

Page 18: ...Display Menu Cont...

Page 22: ...DuoMix Installation Handbook 22...

Page 23: ...DuoMix Installation Handbook 23...

Page 24: ...DuoMix Installation Handbook 24...

Page 25: ...DuoMix Installation Handbook 25...

Page 30: ...DuoMix Installation Handbook 30...