DuoMix Installation Handbook

8

Test the Power Supply

Make sure exposed wires terminals are not in contact with other wires or grounded surfaces. Turn on the power and measure the

voltage between the

Power N — L (15 and 16) terminals using an AC voltmeter, the reading should be between 110 and 130 V (ac).

Test the Powered Inputs

Mixing Demand (

Mix1 Demand & Mix2 Demand)

If a mixing demand is used on the mixing 1 section, measure the voltage between the

Mix1 Demand (1 and 2) terminals. When a call

for heat on the mixing 1 section is present, you should measure between 24 and 240 V (ac) at the terminals. When the demand is

gone, you should measure less than 5 V (ac).

If a mixing demand is used on mixing 2 section, measure the voltage between the

Mix2 Demand (3 and 4) terminals. When a call for

heat on the mixing 2 section is present, you should measure between 24 and 240 V (ac) at the terminals. When the demand is gone,

you should measure less than 5 V (ac).

Test the Outputs

Mixing 1 System Pump (

Mix1 Pmp)

If a mixing system pump is used in the mixing 1 section, make sure power to the terminal block is off and install a jumper between

the

N – Mix1 Pmp (11 and 12) terminals. When power is applied to these terminals, the mixing system pump Mix1 Pmp should start.

If the pump does not turn on, check the wiring between the terminal block and the pump and refer to any installation or

troubleshooting information supplied with the pump. If the pump operates properly, disconnect the power and remove the jumper.

Mixing 2 System Pump (

Mix2 Pmp)

If a mixing system pump is used in the mixing 2 section, make sure power to the terminal block is off and install a jumper between

the

N – Mix2 Pmp ( 7 and 8) terminals. When power is applied to these terminals, the mixing system pump Mix2 Pmp should start.

If the pump does not turn on, check the wiring between the terminal block and the pump and refer to any installation or

troubleshooting information supplied with the pump. If the pump operates properly, disconnect the power and remove the jumper.

Variable Speed Injection Pumps (

Var1 Pmp & Var2 Pmp)

If the variable speed injection pump of the mixing 1 section is used, make sure power to the terminal block is off and install a jumper

between the terminals

N – Var1 Pmp (13 and 14). When power is applied to terminals, the variable speed injection pump should

operate at full speed. If the pump does not operate, check the wiring between the terminal block and the pump and refer to any

installation or troubleshooting information supplied with the pump. If the pump operates properly, disconnect the power and remove

the jumper.

If the variable speed injection pump of the mixing 2 section is used, make sure power to the terminal block is off and install a jumper

between the terminals

N – Var2 Pmp (9 and 10). When power is applied to terminals, the variable speed injection pump should

operate at full speed. If the pump does not operate, check the wiring between the terminal block and the pump and refer to any

installation or troubleshooting information supplied with the pump. If the pump operates properly, disconnect the power and remove

the jumper.

Boiler Enable

If a boiler is connected to the

Boiler Enable (5 and 6) terminals, make sure power to the boiler circuit is off and install a jumper

between the terminals. When the boiler circuit is powered up, the boiler should fire. If the boiler does not turn on, refer to any

installation or troubleshooting information supplied with the boiler and/or Boiler Control. If the boiler operates properly, disconnect

the power and remove the jumper.

Connect the Control

• Make sure all power to the devices and terminal blocks is off and remove any remaining jumpers from the terminals.

• Reconnect the terminal blocks to the control by carefully aligning them with their respective headers on the control and then pushing

the terminal blocks into the headers. The terminal blocks should snap firmly into place.

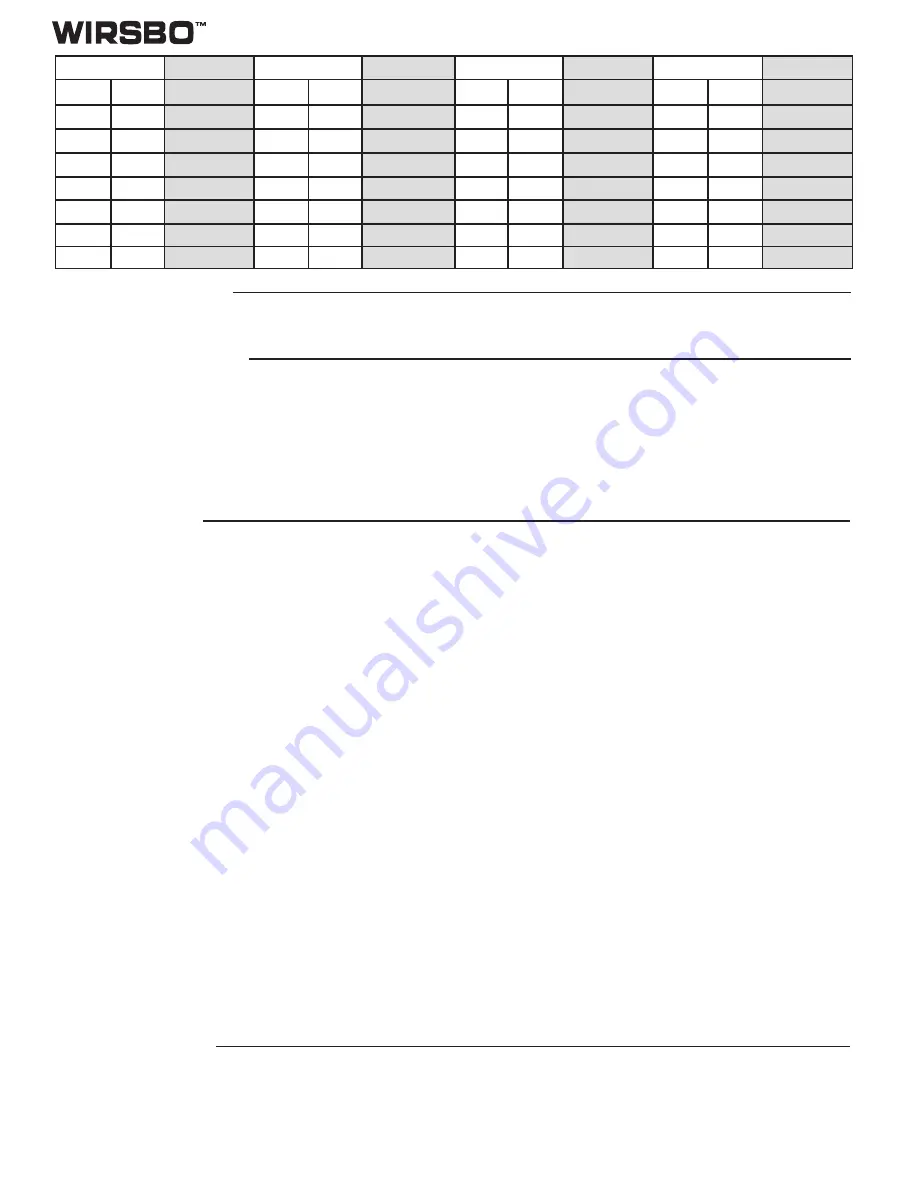

Temperature

Resistance

Temperature

Resistance

Temperature

Resistance

Temperature

Resistance

°

F

°

C

Ω

°

F

°

C

Ω

°

F

°

C

Ω

°

F

°

C

Ω

-50

-46

506,000

20

-7

47,100

90

32

7,400

160

71

1,700

-40

-40

337,000

30

-1

34,400

100

38

5,780

170

77

1,390

-30

-34

228,000

40

4

26,700

110

43

4,730

180

82

1,180

-20

-29

166,000

50

10

19,900

120

49

3,740

190

88

977

-10

-23

116,000

60

16

15,000

130

54

3,100

200

93

838

0

-18

86,500

70

21

11,900

140

60

2,490

210

99

701

10

-12

61,700

80

27

9,170

150

66

2,010

220

104

606

Summary of Contents for DuoMix 201

Page 17: ......

Page 18: ...Display Menu Cont...

Page 22: ...DuoMix Installation Handbook 22...

Page 23: ...DuoMix Installation Handbook 23...

Page 24: ...DuoMix Installation Handbook 24...

Page 25: ...DuoMix Installation Handbook 25...

Page 30: ...DuoMix Installation Handbook 30...