ENGLISH

-

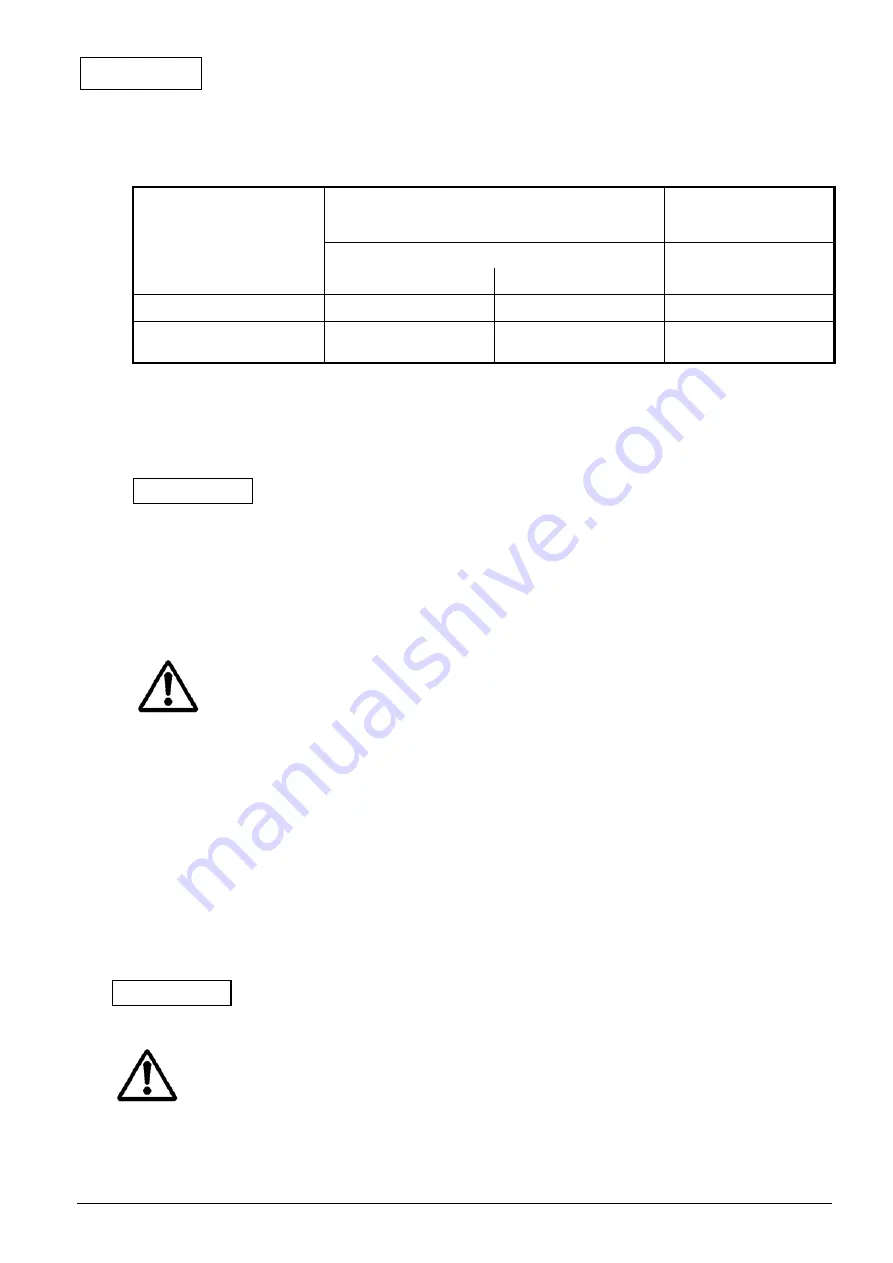

Mains power supply to the terminal depends on rated motor power P2, the supply

voltage and the starting method. For the required terminal bridge connections refer to

table below and Fig.3.

Starting arrangement

Motor power rating

P2

d

3 kW

Motor power rating

P2

t

4 kW

Mains power

Mains power

3 ~ 230 V

3 ~ 400 V

3 ~ 400 V

DOL-Starting

'

-connections (3a) Y-connections (3b)

'

-connections (3a)

Y-

'

-Starting

Remove terminal

bridges (3c)

Not possible

Remove terminal

bridges (3c)

- Comply with respective installation and operating instructions when wiring to auto-

matic pump control gear.

6 Commissioning

-

Pump, suction and inlet piping must be filled and properly vented.

ATTENTION!

The pump must not run dry. Dry-running will damage the mechanical

seal!

- In order to avoid noise and damage due to cavitation a minimum inlet pressure must

be ensured at the pump suction port. This minimum inlet pressure depends on the

operating conditions and the duty point of the pump and must be accordingly calcu-

lated. Significant criteria for calculating the minimum required inlet pressure are the

NPSH-level of the pump at its operating point and the vapour pressure of the liquid.

- Vent pumps by unscrewing its air vent plugs (Fig. 4, 5, pos. 2.1).

Beware of sclading!

Depending on the fluid temperature and the system pressure, if the vent

screw is completely loosened hot liquid or gas can escape or even shoot out

at higth pressure.

- Check the direction of rotation by briefly switching on the pump and make sure that

rotation coresponds with the arrow on the motor (fan cover or flange). If necessary,

correct as follows:

- DOL-Starting: Change any 2 phase wires at the motor terminals (e.g. L1 and L2).

-

Y-

'

-Starting: At the motor terminals change winding start and end terminal connec-

tions respectively of 2 windings (e.g. V1 with V2 and W1 with W2).

-

Ensure a minimum flow of about or higher than 10 % of the maximum flow of the

pump.

- Check that the current input does not exceed the valve indicated on the motor data

plate.

ATTENTION!

The pump must not run for longer than 10 minutes with a flow rate of Q =

0 m³/h (closes discharge valve).

Rrisk of burning / frostbitten if the pump is touched!

Depending on the operating conditions of the pump or installation (fluid tem-

perature), the entire pump can become very hot or very cold.

Keep distance during pump operation!

18