4

M

ounting

4

.

1

G

eneral instructions

M

ake sure that all parts of the instrument in contact with the measured

product

,

especially the sensor element

,

process seal and process

fi

tting

,

are suitable for the existing process conditions such as process

pressure

,

process temperature as well as the chemical properties of

the medium

.

Y

ou can

fi

nd the speci

fi

cations in chapter

"

T

echnical data

"

in the or on

the type label

.

S

elect an installation position you can easily reach for mounting and

connecting as well as later retro

fi

tting of an indicating and adjustment

module

.

T

he housing can be rotated by

330

°

without the use of any

tools

.

Y

ou can also install the indicating and adjustment module in four

di

ff

erent positions

(

each displaced by

90

°

).

U

se the recommended cables

(

see chapter

"

C

onnecting to power

supply

"

)

and tighten the cable gland

.

Y

ou can give your instrument additional protection against moisture

penetration by leading the connection cable downward in front of the

cable entry

.

R

ain and condensation water can thus drain o

ff

.

T

his

applies mainly to outdoor mounting as well as installation in areas

where high humidity is expected

(

e

.

g

.

through cleaning processes

)

or

on cooled or heated vessels

.

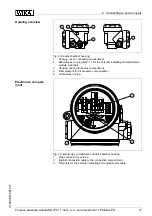

F

ig

.

2

:

M

easures against moisture penetration

T

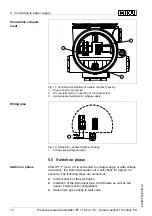

he ventilation of the measuring cell is realised by a

fi

lter element in

the socket of the electronics housing

.

T

he ventilation of the electronics

housing is realised via an additional

fi

lter element around the cable

glands

.

1

)

1

)

W

ith previous instrument versions

,

ventilation and pressure compensation

were carried out together via a

fi

lter element

.

S

uitability for process

conditions

M

ounting position

M

oisture

V

entilation and pressure

compensation

10

P

rocess pressure transmitter

IPT

-

11

V

ers

.

4

.

0

-

ceramic sensor

•

P

ro

fi

bus

PA

4

M

ounting

31547

-

EN

-

081211