10

SECTION 6: MAINTAINING YOUR SNOW THROWER

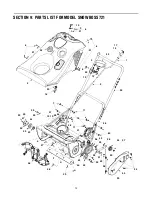

Replacing Belt

•

Remove the belt cover by removing five hex

screws. See Figure 12.

Figure 12

•

Pull up on the idler pulley and slip the belt off the

engine pulley.

•

Push down on the idler pulley and slip the belt off

the auger pulley.

•

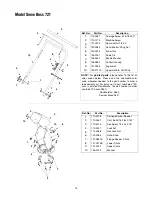

Reassemble new belt. See Figure 13.

•

Reinstall the belt cover.

Figure 13

Replacing Shave Plate

The shave plate is attached to the bottom of the auger

housing and is subject to wear. It should be checked

periodically. There are two wearing edges and the

shave plate can be reversed. See Figure 14.

•

Remove the four carriage bolts and hex lock nuts

which attach it to the snow thrower housing.

•

Install new shave plate, making sure the heads of

the carriage bolts are on the inside of the housing.

•

Adjust the shave plate according to instructions on

page 9. Tighten securely.

Figure 14

Engine

•

Refer to the separate engine manual for all engine

maintenance procedures.

•

Check engine and snow thrower frequently for

loose hardware, and tighten as needed.

Lubrication

•

Lubricate pivot points on the control handle and the

extension spring at the end of the clutch cable with

a light oil once every season and before storage of

the snow thrower at the end of the season.

•

Lubricate the flange keepers on the chute crank

once a season with a light oil making sure the crank

rod moves freely. Remove bolts holding the shroud

to the housing, and lift shroud to access the chute

crank bracket.

WARNING:

Before servicing, repairing, or

inspecting, disengage all clutch levers and stop

engine. Wait until all moving parts have come

to a complete stop. Disconnect spark plug wire

and ground it against the engine to prevent

unintended starting.

Hex

Screw

Hex Screw

Belt Cover

Auger

Pulley

Idler Pulley

Engine

Pulley

Drive

Belt

Remove these hardware

Shave

Plate