9

SECTION 5: MAKING ADJUSTMENTS

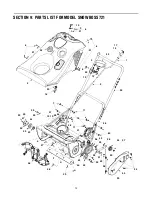

Shave Plate

•

To check the adjustment of the shave plate, place

the unit on a level surface. See Figure 8. The

wheels, shave plate and augers should all contact

level surface. Note that if the shave plate is

adjusted too high, snow may blow under the

housing. If the shave plate wears out excessively,

or the unit does not self-propel, the shave plate

may be too low and needs to be adjusted.

NOTE:

On new units or units with a new shave plate

installed, the augers may be slightly off the ground.

Figure 8

•

To adjust, tip the snow thrower back so that it rests

on the handle. Loosen the four lock nuts and bolts

which secure the shave plate to the housing. See

Figure 9. Move the shave plate to desired position

and retighten the nuts and bolts securely.

Figure 9

Belt Tension

Periodic adjustment of the belt tension may be required

due to normal stretch and wear on the belt. Adjust the

belt tension, following instructions below, if the augers

seem to hesitate while turning although engine

maintains the same speed.

•

The upper hole in the control handle provides

adjustment for belt tension. To adjust, disconnect

the “Z” end of control cable from the bottom hole in

the control handle. See Figure 10 . Hook the cable

into the upper hole in control handle as shown.

Figure 10

If additional adjustment is required, follow steps below.

•

Remove the belt cover by removing five hex screws

that hold it in place. See Figure 12.

•

There are three adjustment holes provided in the

idler bracket assembly. See Figure 11. To adjust,

move the extension spring on the end of the clutch

cable to the next higher adjustment position on the

idler bracket assembly. Reassemble belt cover.

Figure 11

Carburetor

•

Refer to the separate engine manual, packed with

your unit, for carburetor adjustment information.

WARNING:

NEVER attempt to make any

adjustments while the engine is running,

except where specified in the snow thrower

and/or engine operator’s manuals.

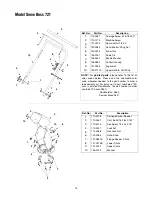

Augers

Shave Plate

Lock Nut & Carriage Bolt

WARNING:

If any adjustments need to be

made to the engine while the engine is running

(e.g. carburetor), keep clear of all moving parts.

Be careful of muffler, engine and other

surrounding heated surfaces.

Upper

Hole

Clutch

Cable

Control

Housing

Auger

Pulley

Idler

Bracket

Spring on

End of Clutch

Cable

High Position

Middle Position

Low Position