11

SECTION 7: OFF-SEASON STORAGE

•

Clean snow thrower thoroughly.

•

Lubricate as instructed above with a light oil.

•

Follow “Storage” instructions in the Engine Manual.

•

Store in a clean, dry area. Block the snow thrower

up so it is not resting on the rubber auger blades.

NOTE:

When storing any type of power equipment in a

poorly ventilated or metal storage shed, care should be

taken to rustproof the equipment, especially springs,

cables and all moving parts.

SECTION 8: TROUBLESHOOTING GUIDE

NOTE:

For repairs beyond the minor adjustments listed above, call the White Outdoor Customer Dealer Line at

1-(800)-949-4483 for the dealer nearest you. Refer to separate engine manual, packed with your snow

thrower, for engine information.

WARNING:

Never store engine with fuel in

tank indoors or in enclosed, poorly ventilated

areas where fuel fumes may reach an open

flame, spark or pilot light as on a furnace, water

heater, clothes dryer, or other gas appliance.

Problem

Cause

Remedy

Engine fails to start

1.

Fuel tank empty, or stale fuel

2.

Blocked fuel line

3.

Key not in ON position

4.

Spark plug wire disconnected

5.

Faulty spark plug

6.

Engine not primed

7.

Engine flooded with excessive priming

1.

Fill tank with clean fresh gasoline.

2.

Clean fuel line

3.

Insert key and turn to ON position

4.

Connect wire to spark plug.

5.

Clean spark plug, readjust gap, or replace.

6.

Prime engine four times.

7.

Wait at least ten minutes before starting.

Engine runs erratic

1.

Unit running on choke

2.

Fuel line blocked, or stale fuel

3.

Water or dirt in fuel system

4.

Carburetor out of adjustment

1.

Move choke lever to OFF position.

2.

Clean fuel line and fill tank with fresh,

clean gasoline.

3.

Refer to engine manual for remedy.

4.

Refer to engine manual for remedy.

Engine overheats

1.

Carburetor out of adjustment

1.

Refer to engine manual for instruction.

Loss of power

1.

Spark plug wire loose

2.

Vent in gas cap plugged

1.

Connect and tighten spark plug wire.

2.

Clear vent.

Excessive vibration

1.

Loose parts or damaged auger

1.

Stop engine immediately and disconnect

spark plug wire. Check for possible

damage. Tighten all bolts and nuts. Repair

as needed. If the problem persists, take

unit to an authorized service dealer.

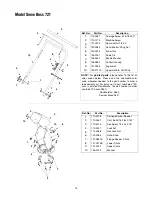

Unit fails to self-propel 1.

Drive cable out of adjustment

2.

Drive belt loose or damaged

1.

Adjust drive cable following instructions on

page 9 of this manual.

2.

Replace drive cable.

Unit fails to discharge

snow

1.

Discharge chute clogged

2.

Foreign object lodged in auger

3.

Drive cable not adjusted properly

4.

Drive belt loose or damaged

1.

Stop engine immediately and disconnect

spark plug wire. Clean discharge chute

and the auger housing.

2.

Stop engine immediately and disconnect

spark plug wire. Remove object .

3.

Adjust drive cable following instructions on

page 9 of this manual.

4.

Replace drive belt.