WHL-052 Rev. 4.28.16

15

D. Expansion Tank

Expansion Tank and Make-Up Water

1. Ensure that the expansion tank is sized to correctly handle

boiler and system water volume and temperature.

Undersized expansion tanks cause system water to be lost

from the relief valve, causing make-up water to be added.

Eventual boiler failure can result due to excessive make-

up water addition.

SUCH FAILURE IS NOT COVERED BY

WARRANTY.

2. The expansion tank must be located as shown in

Applications, this manual, or following recognized design

methods. See expansion tank manufacturer’s instructions for

details.

3. Connect the expansion tank to the air separator only if the

air separator is on the suction side of the circulator. Always

install the system fill connection at the same point as the

expansion tank connection to the system.

4. Most chilled water systems are piped using a closed type

expansion tank.

DIAPHRAGM (OR BLADDER) EXPANSION TANK

Always install an automatic air vent on top of the air separator

to remove residual air from the system.

Expansion tanks must be sized according to total system

volume. This includes all length of pipe, all fixtures, boilers,

etc. Failure to properly size for system expansion could result

in wasted time, money, possible property damage, serious

injury, or death.

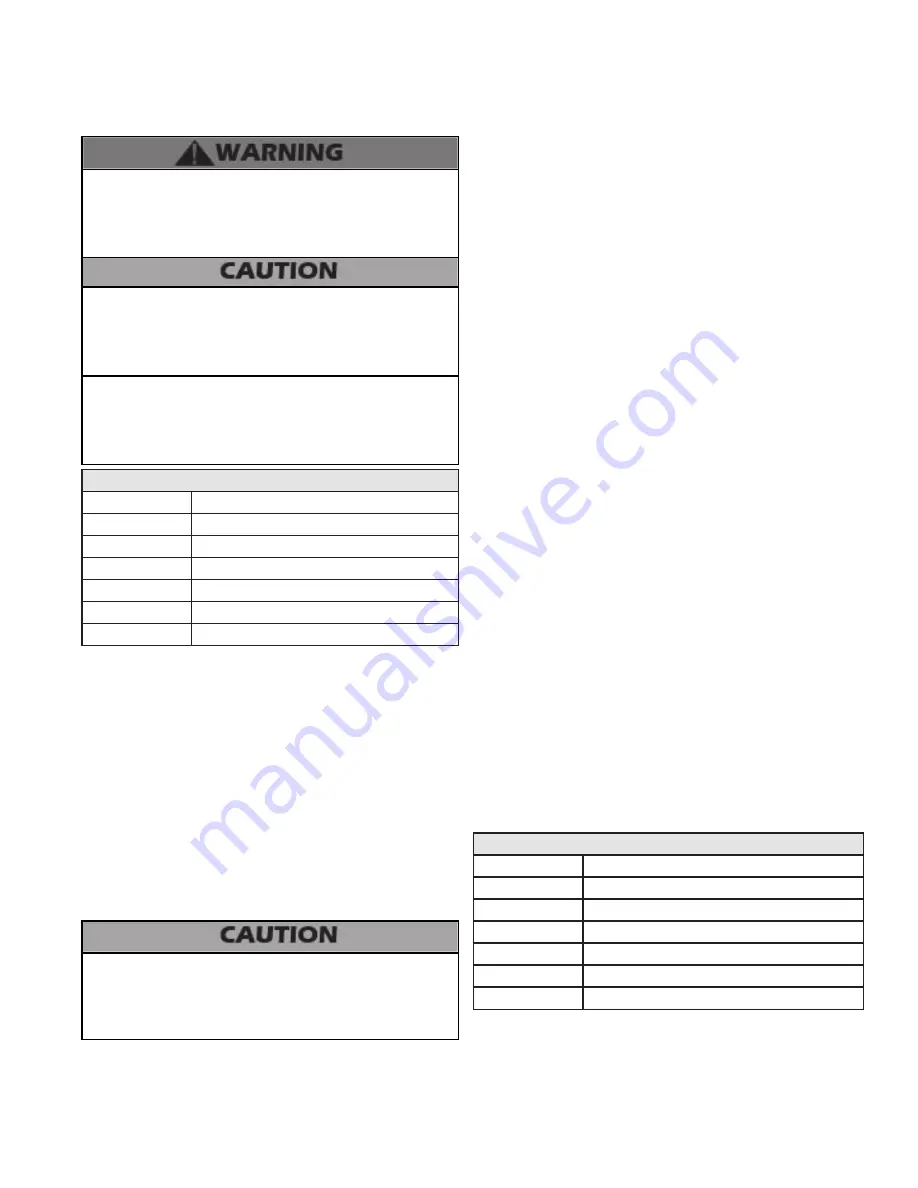

Expansion Tank Sizing

Model

Heat Exchanger Volume (Gallons)

80

1.4

110

1.7

150

2

220

2.6

299 / 301

3.1

399

3.7

Table 2 - Expansion Tank Sizing

DO NOT

install automatic air vents on closed type expansion

tank systems. Air must remain in the system and return to the

tank to provide an air cushion. An automatic air vent would

cause air to leave the system, resulting in improper operation

of the expansion tank.

E. Circulators

Sizing Space Heat System Piping

1. See Applications in this manual. In all diagrams, the space

heating system is isolated from the boiler loop by the primary/

secondary connection.

DO NOT

use the boiler circulator in any location other than

the ones shown in this manual. The boiler circulator location

is selected to ensure adequate flow through the boiler.

Failure to comply with this caution could result in unreliable

performance and nuisance shutdowns from insufficient flow.

2. Size the piping and components in the space heating system

using recognized design methods.

F. Hydronic Piping with Circulators, Zone Valves, and

Multiple Boilers

This boiler is designed to function in a closed loop hydronic

system. We have included a temperature and pressure gauge

that allows the user to monitor the system pressure and outlet

temperature from the boiler. It is important to note that the

boiler has a minimal amount of pressure drop that must be

calculated when sizing the circulators. Unless the system has a

closed type expansion tank, each boiler installation must have

an air elimination device that will remove air from the system.

Install the boiler so the gas ignition system components

are protected from water (dripping, spraying, etc.) Allow

clearance for basic service of boiler circulator, valves and other

components.

Observe the minimum 1” clearance around all uninsulated hot

water pipes when openings around pipes are not protected by

non-combustible materials.

On a boiler installed above radiation level, some states and local

codes require a low water cut off device, which is an optional part

available through Westinghouse (Part # 7450P-904). Check with

local codes for additional requirements. If the boiler supplies hot

water to heating coils in air handler units, flow control valves or

other devices must be installed to prevent gravity circulation of

boiler water in the coils during the cooling cycle.

Chilled water medium must be piped in parallel with the boiler.

Freeze protection for new or existing systems must use glycol

that is specifically formulated for this purpose. Antifreeze must

include inhibitors that will prevent the glycol from attacking

the metallic system components. Make certain that the system

fluid is checked for the correct glycol concentration and inhibitor

level. The system should be tested at least once a year and as

recommended by the producer of the glycol solution. Allowance

should be made for the expansion of the glycol solution in the

system piping. Example: 50% by volume glycol solution expands

4.8% in volume for a temperature increase from 32

o

F to 180

o

F,

while water expands 3% with the same temperature rise.

G. Circulator Sizing

Minimum Boiler Flow Rates

Model

Minimum Flow (GPM)

80

5.3

110

7.3

150

10

220

14.6

299 / 301

20

399

26

Table 3 - Minimum Flow Rates

In addition, the heat exchanger has a minimum total water

volume that must be taken into account when sizing the

circulator. Minimum flow rates are listed in the table below.

The heat exchanger has a pressure drop that must be considered

in your system design. Refer to Table 4 for pressure drop through

the heat exchanger.

Summary of Contents for WBRE110

Page 13: ...WHL 052 Rev 4 28 16 13 Figure 5 Boiler Dimensions NOTE All Dimensions Are Approximate ...

Page 37: ...WHL 052 Rev 4 28 16 37 Figure 25 Internal Connection Diagram ...

Page 62: ...WHL 052 Rev 4 28 16 62 Figure 30 Combustion System Replacement Parts 80 220kBTU Models ...

Page 63: ...WHL 052 Rev 4 28 16 63 Figure 31 Combustion System Replacement Parts 299 399kBTU Models ...

Page 64: ...WHL 052 Rev 4 28 16 64 Figure 32 Cabinet Replacement Parts All Models ...

Page 65: ...WHL 052 Rev 4 28 16 65 Figure 33 Cabinet Replacement Parts All Models ...