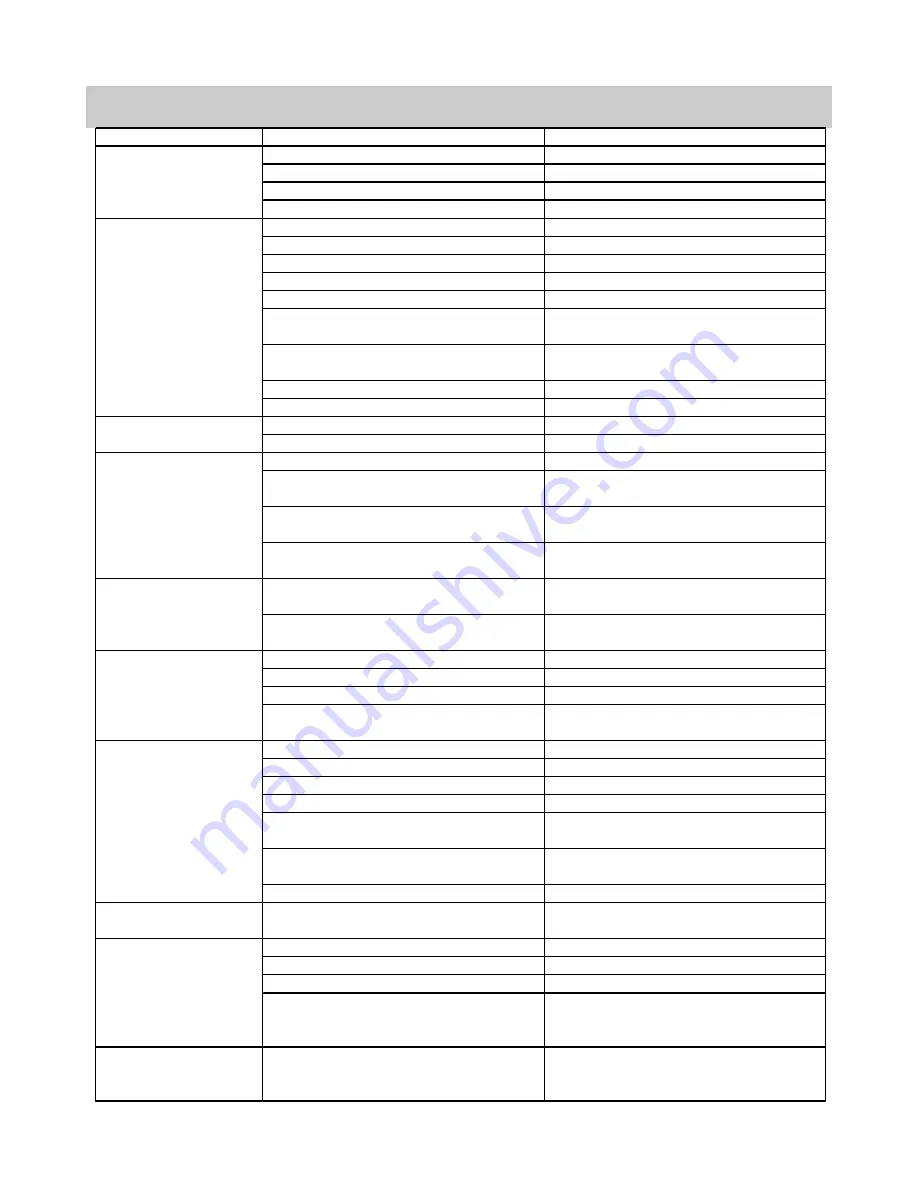

Trouble Shooting

Issue

Possible

Cause

Possible

Solution

1.

No

power

supply.

Check

electrical

service,

fuse,

etc.

2.

Defective

circuit

board.

Replace

faulty

parts.

3.

Power

failure.

Reset

time

of

day.

4.

Defective

meter.

Replace

turbine

meter.

1.

By

‐

pass

valve

open.

Close

by

‐

pass

valve.

2.

Out

of

salt

or

salt

level

below

water

level.

Add

salt

to

tank.

3.

Plugged

injector

/

screen.

Clean

parts.

4.

Flow

of

water

blocked

to

brine

tank.

Check

brine

tank

refill

rate.

5.

Hard

water

in

hot

water

tank.

Repeat

flushing

of

hot

water

tank

required.

6.

Leak

between

valve

and

central

tube.

Check

if

central

tube

is

cracked

or

o

‐

ring

is

damaged.

Replace

faulty

parts.

7.

Internal

valve

leak.

Replace

valve

seals,

spacer,

and

piston

assembly.

8.

Reserve

capacity

setting

too

low.

Increase

reserve

capacity.

9.

Not

enough

capacity.

Increase

salt

dosage.

1.

Refill

time

is

too

high.

Check

refill

time

setting.

2.

Defective

flow

control.

Replace.

1.

Iron

or

scale

build

up

in

line

feeding

unit.

Clean

pipes.

2.

Iron

build

up

inside

valve

or

tank.

Clean

control

and

add

resin

cleaner

to

clean

bed.

Increase

regeneration

frequency.

3.

Inlet

of

control

plugged

due

to

foreign

material.

Remove

piston

and

clean

control

valve.

4.

Deteriorated

resin.

(Maybe

caused

from

high

chlorine

or

chloramines.)

Re

‐

bed

unit.

Consider

adding

carbon

pre

‐

treatment.

1.

Air

in

water

system.

Check

well

system

for

proper

air

eliminator

control.

2.

Incorrect

drain

line

flow

control

(DLFC)

button.

Check

for

proper

flow

rate.

1.

Plugged

injector

or

screen.

Clean

parts.

2.

Valve

not

regenerating.

Replace

circuit

board,

motor,

or

control.

3.

Foreign

material

in

brine

valve.

Clean

parts.

4.

Unit

not

drawing

brine.

Check

for

vacuum

leak

in

brine

line

connections.

1.

Drain

line

flow

control

is

plugged.

Clean

parts.

2.

Injector

or

screen

is

plugged.

Clean

parts.

3.

Inlet

pressure

too

low.

Increase

pressure

to

25

PSI.

4.

Internal

valve

leak.

Replace

seals,

spacers,

and

piston

assembly.

5.

Safety

valve

closed.

Check

for

leak

in

brine

line

connections.

Replace

safety

float

assembly.

6.

Vacuum

leak

in

brine

line.

Check

for

leak

in

brine

line

connections.

Tighten

all

connections.

7.

Drain

line

has

kink

in

it

or

is

blocked.

Check

drain

line.

H.

Valve

continuously

cycles.

1.

Defective

position

sensor

PCB.

Replace

faulty

parts.

1.

Valve

settings

incorrect.

Check

valve

settings.

2.

Foreign

material

in

control

valve.

Clean

control.

3.

Internal

leak.

Replace

seals,

spacers,

and

piston

assembly.

4.

Piston

is

stuck

in

position.

Motor

may

have

failed

or

gears

have

jammed

or

disengaged.

Check

for

power

to

motor.

Check

for

loose

wire.

Check

for

jammed

gears

or

gears

disengaged.

Replace

faulty

parts.

J.

Valve

makes

beeping

sound.

1.

The

piston

has

not

advanced

to

the

next

cycle

position

properly.

Check

for

power

to

motor.

Check

for

loose

wire.

Check

for

jammed

gears

or

gears

disengaged.

I.

Flow

to

drain

continuously.

G.

Unit

fails

to

draw

brine.

A.

Unit

fails

to

initiate

a

regeneration

cycle.

B.

Water

is

hard.

E.

Resin

in

drain

line.

C.

Salt

use

is

high.

D.

Low

water

pressure.

F.

Too

much

water

in

brine

tank.

22

Summary of Contents for HTO-185HEUF

Page 7: ...Installation 7...

Page 20: ...Power Head Exploded View 20...