14

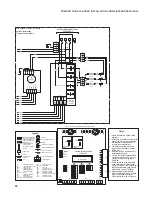

PREMIER 2 SINGLE-SPEED INSTALLATION AND MAINTENANCE MANUAL

ECM2

Fan Motor

NOTE 9

P11

2

3

4

5

1

PB2

4

3

2

1

Auxiliary Electric Heat Power

208-230/60/1

G

Violet

Blu

With optional Premier ' EA' Series

Auxiliary ElectricHeat

Typical schematic shown

2

3

HE1

TS1

HE2

HE3

TS3

HE4

TS4

1

2

3

4

P7

L4

L2

L2

G

NOTE 5

Grn

Pink

Yel

Blk

Gray

Pink

Yel

Blk

Gray

Gray

Blk

Yel

Pink

Gray

Pink

Blk

Yel

Pink

Yel

Blk

Gray

Pink

Yel

Blk

Gray

Grn

P8

F2

P9

ER1

ER2

ER3

ER4

L1

L1

L3

NO

NO

NO

NO

Brn

Or

Brn

Or

5

4

Pink

Orange

White

Tan

Blue

15

10

16

3

8

On/Off

PWM

RPM

C2

RPM grnd

P12

Violet

Blue

Yellow

Black

Gray

Red

Premier2

EA Series PCB

17P514A01

T

1

3

2

G

P

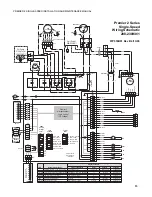

Thermistor

Light emitting diode - Green

Relay coil

Capacitor w/ bleed resistor

Switch - Condensate overflow

Switch - High pressure

Switch - Low pressure

Switch -Hot water On/Off

Polarized connector

Factory low voltage wiring

Factory line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

DC voltage PCB traces

Internal junction

Quick connect terminal

Wire nut

Field wire lug

Ground

Fuse

L1

CC -

CO -

CR1 -

CR2-

CR3 -

CR4 -

ER1 to ER4 -

F1 and F2 -

FP -

HE -

HP -

HWL -

LP -

PB1, PB2 -

PS -

RV -

SW1 -

SW2 -

SW3 -

SW4 -

TS -

Compressor contactor

Condensate overflow sensor

DHW pump relay

Loop pump relay

PSC fan speed relay

PSC fan power relay

Aux heat stage relays

Fuses

Freeze protection sensor

Heater element

High pressure switch

Hot water limit sensor

Low pressure switch

Power blocks

Power strip

Reversing valve coil

DIP package 12 position

DIP package 8 position

DIP package 5 position

Hot water pump enable switch

Thermal limit switch

Legend

Relay contacts-

N.O., N.C.

Notes:

L1

L2

Single Disconnect Power

208-230/60/1

Aux Elect Power

208-230/60/1

L1

L2

L1

L2

AT Unit Power

208-230/60/1

CSA installed units only

Local codes may require a single

source of power supply

Breaker box

furnished by

installer

Circuit Breakers

1 2 3

1

P4

On

Off

SW1

240V - L2

240V - L1

Fused L2

Fused L2

Fused L2

F1

F1

R

R

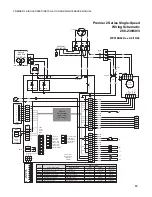

Microprocessor

Premier2 Series Logic Board

Premier2 Logic Board (Single-Speed Configuration) Physical Layout

CR2- Loop Pump

N.O.

240V - L2

240V - L1

C

C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

P6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

P5

Fused L2

Fused L1

CR1- DHW Pump

N.O.

N.O.

CR4

Com

CC

CC-GND

CCLO

CCHI

1

2

ACC

NO

ACC

NC

3

ACC

COM

P3

2

3

4

5

6

7

8

9

10

11

12

1

On

Off

SW2

2

3

4

5

6

7

8

1

On

Off

SW3

2

3

4

5

N.O.

CR3

Com

N.C.

P1

R

C Y1 Y2

G

O

W

LO

1

2

3

4

5

6

7

8

C

C

SL1

IN

2

3

4

5

SL1

Out

P2

SL2

IN

6

7

SL2

Out

1

Shut

Down

1

1

2

3

P10

4

5

6

P2

1

TS2

1 - Switch blue and red wires for 208V

operation.

2 - Connection of remote unit that does not

have a loop pump for slave operation.

3 - 24V Accessory relay (see SW2 - 3 for

description of operation).

4 - The blk/wh and gray/wh wires are

removed when Aux Heat is installed .

5 - Buss lugs L1 and L2 can be removed and

dual power wire sets connected directly to

box lugs L1, L2, and L3, L4.

6 - DHW pump only in models with hot water

generation option.

7 - Air Flow Configuration Example: SW1

configured for dip 3 as low, dip 5 as medium,

and dip 7 as high speed ECM2 fan.

8 - SW3-4 should be in the ON position when

using Premier 2 Electric Heat control

17P514A01, and it should be in the OFF

position when using Premier Electric Heat

control 17P501A01.

9 - When using thermostat TA32E12, SW2 -8

should be in the "on" position. When using

24VAC thermostats, SW2-8 should be in the

"off" position.

Summary of Contents for AT019D

Page 20: ......

Page 21: ......

Page 26: ...26 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL Notes...

Page 27: ...27 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL...