2

PREMIER 2 SINGLE-SPEED INSTALLATION AND MAINTENANCE MANUAL

Physical Data

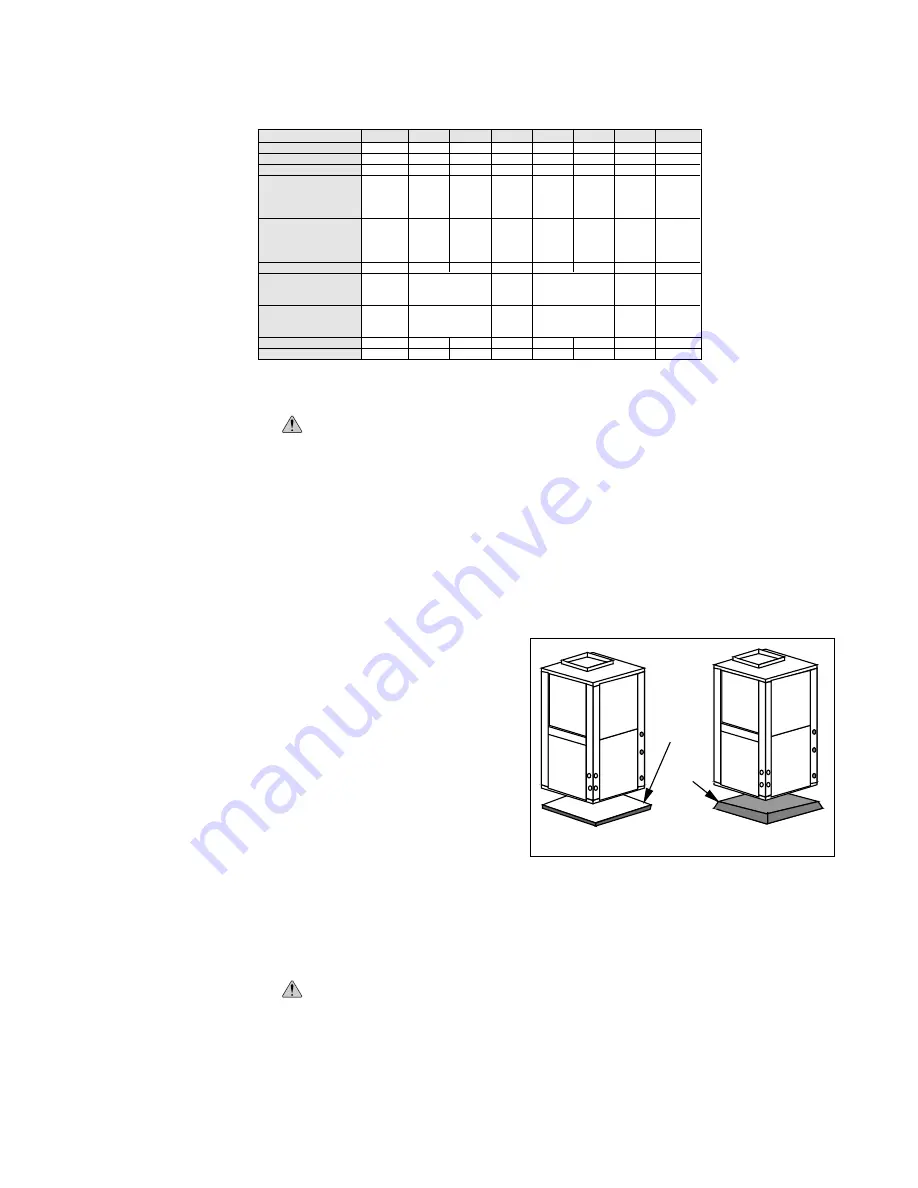

Figure 1

–

Vertical Unit Mounting

UNIT LOCATION

CAUTION:

Do not locate in areas where ambient conditions are not maintained within

45

°

-95

°

F and less than 75% relative humidity.

Locate the unit in an indoor area that allows for easy removal of the filter and access panels.

Location should have enough space for service personnel to perform maintenance or repair.

Provide sufficient room to make water, electrical and duct connection(s). If the unit is located in a

confined space, such as a closet, provisions must be made for return air to freely enter the space

by means of a louvered door, etc. Any access panel screws that would be difficult to remove

after the unit is installed should be removed prior to setting the unit. On horizontal units, allow

adequate room below the unit for a condensate drain trap and do not locate the unit above

supply piping. These units are not approved for outdoor installation and, therefore, must be

installed inside the structure being conditioned.

SETTING VERTICAL UNITS

Vertical units are available in left or

right air return configurations. Top flow

vertical units should be mounted level on a

vibration absorbing pad slightly larger than

the base to provide isolation between the

unit and the floor. It is not necessary to

anchor the unit to the floor (see Figure 1).

Bottom flow units should be mounted level

and well sealed to the floor to prevent

air leakage.

NOTE:

If access to the left side of the

unit will be limited after installation, remove the two mounting screws on the left side of the

control box before setting the unit (leave the two front mounting screws intact). This will allow the

control box to be removed with only the two front mounting screws for future service.

SETTING HORIZONTAL UNITS

CAUTION:

Do not use rods smaller than 3/8” diameter since they may not be strong

enough to support the unit. The rods must be securely anchored to the ceiling.

Horizontal units are available with side or end discharge and may be field converted from one

to the other by replacing the discharge panel (TB920813) with a new panel which must be

ordered separately. Horizontal units are normally suspended from a ceiling by four 3/8” diameter

threaded rods (six on ATH040-066). The rods are usually attached to the unit by hanger bracket

kits furnished with each unit.

General

Installation

Information

AAAAA

AAAAA

AAA

AAA

AAA

AA

AA

AA

AA

Vibration

Absorbing

Mesh

Air

Pad

AT022C/D

AT019D

MODEL

AT028D AT034D AT040D AT046D AT056D AT066D

9 x 7

ECM2-1/2

Rotary

19 x 20

2.6

3

18 x 21

2.6

3

43.0

189

210

20 x 24

EAF2024

18 x 24

EAF1824

24 x 24

EAF2424

2-18 x 18

EAF1836

9 x 7

ECM2-1/2

Scroll

24 x 20

3.3

3

18 x 27

3.4

3

62.0

258

260

9 x 7

ECM2-1/2

Rotary

24 x 20

3.3

3

18 x 27

3.4

3

58.0

252

256

11 x 10

ECM2-1/2*

Scroll

28 x 25

4.9

3

20 x 35

4.9

3

85.0

320

337

11 x 10

ECM2-1/2*

Scroll

28 x 25

4.9

3

20 x 35

4.9

3

88.0

336

339

9 x 7

ECM2-1/2*

Scroll

27 x 20

3.8

3

18 x 30

3.8

3

65.0

274

270

2-14 x 24

EAF2428

2-18 x 18

EAF1836

Fan Wheel

Fan Motor

Compressor

Air Coil: (Vertical)

Dimensions

Area (sq. ft.)

Rows

Air Coil: (Horizontal)

Dimensions

Area (sq. ft.)

Rows

R22 (oz.)

Filter-1" (Vertical)

Throwaway

Electrostatic

Filter-1" (Horizontal)

Throwaway

Electrostatic

Weight (lbs.)-Vertical

Weight (lbs.)-Horizontal

* Optional 1 hp ECM2 fan motor available

11 x 10

ECM2-1

Scroll

32 x 25

5.6

3

20 x 40

5.6

3

116.0

2-10x30

1-12x30

EAF2042

1-18x20

1-24x20

EAF2042

399

429

11 x 10

ECM2-1

Scroll

36 x 25

6.3

3

20 x 45

6.3

3

98.0

3-12x30

EAF2048

2-24x20

EAF2048

426

456

2-14 x 30

EAF2830

1-20 x 12, 1-20 x 25

EAF2037

Summary of Contents for AT019D

Page 20: ......

Page 21: ......

Page 26: ...26 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL Notes...

Page 27: ...27 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL...