3

PREMIER 2 SINGLE-SPEED INSTALLATION AND MAINTENANCE MANUAL

DUCT SYSTEM

CAUTION:

Be sure to remove the shipping material from the blower throat before connect-

ing ductwork.

An air outlet collar is provided on vertical top flow units and all horizontal units to facilitate a

duct connection (vertical bottom flow units have no collar). A flexible connector is recommended

for discharge and return air duct connections on metal duct systems. Uninsulated duct should be

insulated with a minimum of 1" duct insulation. Application of the unit to uninsulated ductwork in

an unconditioned space is not recommended as the unit’s performance will be adversely affected.

For vertical bottom flow units, cut the floor opening for air discharge at least 1/2" larger than

the unit air outlet. Protect opening edges in combustible flooring with a sheet metal

overwrap. Discharge air only into a suitable supply duct system and do not locate

registers or openings directly under unit air outlet.

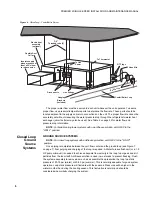

Lay out the threaded rods per the dimensions in Figure 2. Assemble the hangers to the unit

as shown. Securely tighten the brackets to the unit using the weld nuts located on the underside

of the bottom panel. When attaching the hanger rods to the bracket, a double nut is recom-

mended since vibration could loosen a single nut. The unit should be pitched approximately

1/4” towards the drain in both directions to facilitate the removal of condensate. (see Figure

5A on page 5). Use only the bolts provided in the kit. The use of longer bolts could damage

internal parts.

Some residential applications require the installation of horizontal units on an attic floor. In

this case, the unit should be set in a full size secondary drain pan on top of a vibration absorbing

mesh. The secondary drain pan prevents possible condensate overflow or water leakage

damage to the ceiling. The secondary drain pan is usually placed on a plywood base isolated

from the ceiling joists by additional layers of vibration absorbing mesh.

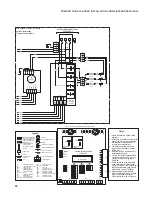

A

C

B

D

E

Air Handler

Section

Compressor

Section

Figure 2–

Hanger Location and Assembly

Bolt and

Lockwasher

Vibrator

Isolator

Washer

3/8" Threaded Rod

(not supplied)

Hex Nuts

(not supplied)

MODEL

C

B

A

D

E

ATH019

ATH022, 028, 34

ATH040, 046

ATH056

ATH066

24.8

24.8

27.8

27.8

27.8

-

-

29.9

29.9

29.9

51.5

61.5

70.5

75.5

80.5

53.0

63.0

72.0

77.0

82.0

22.5

22.5

25.5

25.5

25.5

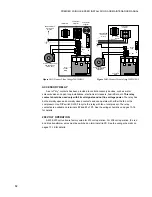

Figure 3–

Optional Filter Rack

D

C

A

B

E

Door side mountable

on either end

Horizontal Filter Rack

MODEL

C

B

A

D

E

Model No.

24.5

36.1

36.1

37.1

42.1

47.1

5.5

5.5

5.5

5.5

5.5

5.5

DCH1824

DCH1836

DCH1836

DCH2037

DCH2042

DCH2048

18.1

18.1

18.1

20.1

20.1

20.1

0.5

0.5

0.5

0.6

0.6

0.6

2.5

2.0

2.0

2.2

2.2

2.2

1" duct connection is provided.

Construction is air tight.

ATH019

ATH022, 028

ATH034

ATH040, 046

ATH056

ATH066

Summary of Contents for AT019D

Page 20: ......

Page 21: ......

Page 26: ...26 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL Notes...

Page 27: ...27 PREMIER 2 SINGLE SPEED INSTALLATION AND MAINTENANCE MANUAL...