11 November 2020

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

All Dimension are in mm

…….

Copyright on all products and Specifications ©

10

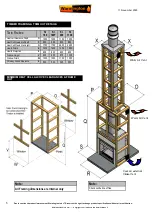

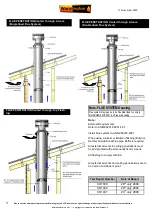

FLUE DETAILS DIMENSIONS

Minimum Flue Height

Flue Height

4800

Measured From Top of Adaptor

B + F + 4800

Flue details

No:

SI

780

SI

780T

SI

900

SI

1100

Cowl

1

300

300

325

350

Cone

1

300

300

325

350

Top Spider

1

300

300

325

350

Flue Diameter

4

300

300

325

350

Baffle

4

350

350

375

400

Liner Diameter

4

400

400

425

450

Spacer

4

300/350

300/350

325/375

350/400

Spacer

4

350/400

350/400

375/425

400/450

NOTE:

Ensure that a Standard Tested Warmington Flue system is used on the

Warmington

fires.

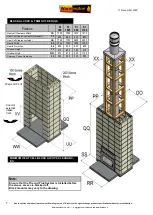

FLUE SYSTEM INSTALLATION GUIDE

This is a general installation guide only –

Contact a

“

NZHHA Installer

”

for Installation Advice.

1.

Install the first length of flue pipe with the crimped end down, inside the Adaptor collar, ensure that the flue

pipe is sealed into the collar with exhaust sealant. Rivet the flue in 3 places around the Adaptor collar.

Place a spacer around the flue pipe approximitaly150mm above the adaptor collar. Secure in position by

tightening the screw and nut.

2.

Install the second length of flue pipe with the crimped end down and fit by riveting in at least 3 places

around the flue pipe joint. Ensure that the flue is sealed into position with sealant.

3.

Install the first section of flue pipe liner with the Crimped end up, over the flue pipe and over the spacer that

is fixed to the flue pipe. This spacer will keep the liner concentric about the flue pipe.

4.

Position flue spacer at the flue pipe joint for every length of

“

Flue pipe

”

and

“

Liner

”.

Repeat the Steps from 1 –

4

to the installed required height of the flue system. The flue system is to comply

with ASNZS 2918:2001 4.9.1

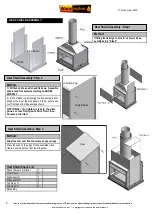

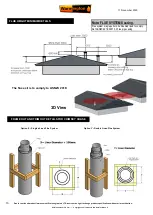

1.

NOTE:

The last length of flue pipe needs to extend past the liner so that when the

“

top spider

”

and the

“

Flashing cone

”

are fitted, that the

“

flashing cone

”

and the

“

flue pipe

”

are

flush,

or that the

“

flue pipe

”

is

5mm lower

that the

“

Flashing cone

”.

2.

Fit the

“

Top Spider

”

into position, ensure that the legs of the spider are fitted inside the liner and that the

spider is positioned hard down onto the liner and tighten with the screw and nut.

3.

Place the

“

Flashing cone

”

over the

“

flue pipe

”

and press hard down onto the

“

Top Spider

”.

(Note that the

“

Flue pipe

”

and the

“

Flashing Cone

”

are either flush or the

“

Flue pipe

”

is 5mm Lower than the

“

Flashing

cone

”.)

Ensure that the

“

Flashing cone

”

is clear for the venting from the

“

Liner

”

and the

“

flue pipe

”.

4.

Fit the

“

Cowl

”

to the top of the flue pipe. The

“

Cowl

”, “

Flashing cone

”,

and the

“

Flue pipe

”

can be secured

to each other with the uses of a stainless steel self tapping screw. This will allow the

“

Cowl

”

to be re-

moved for cleaning.

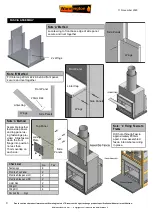

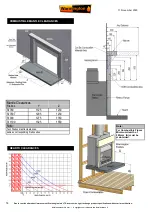

5.

Flue system may require Bird Proofing due to the installation and locations, discuss this with your installer

for the best advice.

6.

If the Flue system is installed into a

“

Chimney Chase

”,

allow for air vent as close to the top of the chase

as practical, or allow venting through the

“

Chimney Chase Flashing

”.

A

“

Venting Flashing cone

”

and a

25mm gap around the Liner with a

“

Venting Flashing Cone

-

Spider

”

can be used.

•

a “the flue pipe shall extend not less than 4.6m above the top of the floor protector.”

•

b “ the minimum height

of the flue system within 3 m distance from the highest point of the roof shall be 600mm

above that point.”

•

c “the minimum height of the flue system further than 3 m from the highest point of the roof shall be 1000mm

above the roof penetration.”

•

d “no part

of any building lies in or above a circular area described by a horizontal radius of 3 m about the flue

system exit.”

Note: FLUE SYSTEMS casing.

The flue system requires to be doubled lined to comply

with AS/NZS:2918:2001 4.3 Flue pipe casing.