11

warmhaus.com

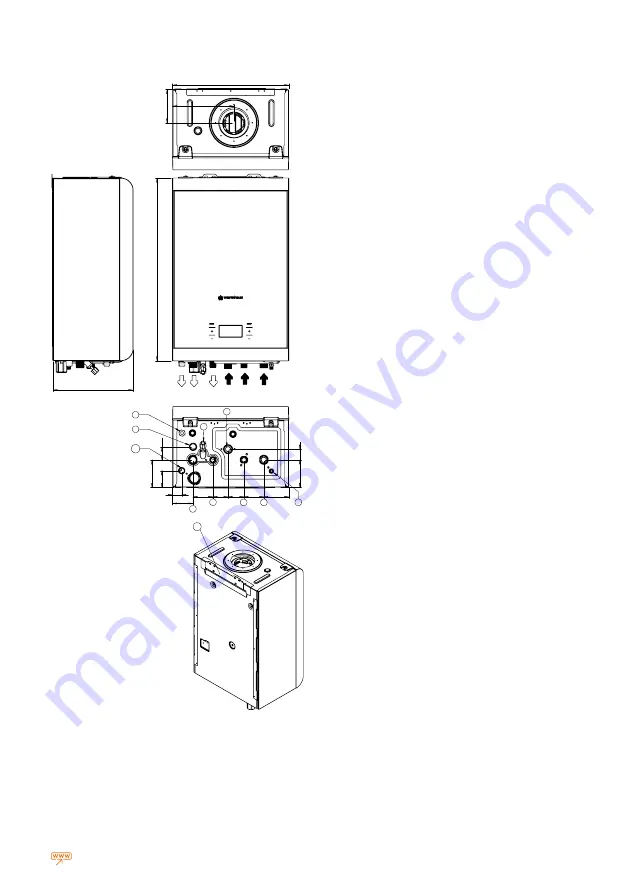

2.2.4. Dimensions and Connections

2.2.5. Natural Gas and LPG Connection (Device

Category I

2H

, II

2H3P

)

Our products are manufactured to be operated with

methane gas (G20) and L.P.G. Gas supply pipes should

be equal to or higher than 3/4”G. Prior to making the gas

connection, a studious internal cleaning should be made

to all fuel supply installation pipe furnhishings as possible

wastes may distort smooth operation and reliability of

the combi boiler. It should be controlled whether the gas

distributed from the main line is as envisaged (see the

table on the combi boiler device).

In case of having differences, an intervention should be

made on the combi boiler and converted to other gas

type (consult our authorized services in case of gas

change). Also, in case of being inadequate, the network

dynamic pressure (methane or LPG) to be used for

supplying the combi boiler should be controlled regarding

the impact on combi boiler power and difficulties

possible for the user. Ensure the correctness of gas valve

connection. Flammable gas supply pipe should be able to

supply correct adequate gas amount to the boiler when

the combi boiler is at full power and be projected and

sized according to local gas company specification and

instructions in order to guarantee the device efficiency.

Connection system should comply with legal regulations.

2.2.6. Flammable Gas Quality

The combi boiler is designed to be used with pure fuel

not containing any foreign substances; therefore, required

filter systems must be available in the gas supply line (for

ensuring purification of the fuel).

2.2.7. In Case of Using LPG Tank

For heat requirements over 24 kW, LPG tank usage is

recommended instead of LPG bottle. New LPG stock

tanks may contain settled gas residues (nitrogen) and this

pauperises the mixture assigned to that device and cause

abnormal operations.

- Various alloy layers may be formed during stocking LPG

gas in tanks depending on mixture compositions. That

causes a change in heating power of mixture assigned to

the device and changes efficiency of the device.

2.2.8. In Case of Using Bottled Gas

• 300 mmH

2

O pressurized hood should be used for LPG.

• 500 mmH

2

O hood should not be used.

• 370 mmH

2

O pressurized hood should be used for

Propane.

• Do not place tubes at cold places having risk of snow

for preventing frost during winter months.

• Do not place tubes in hot places containing ovens,

fireplaces for preventing dangers!

• Do not make connection with single tube and use LPG

collector set for double, triple uses.

• The distance between the collector and tube should be

maximum 125 cm.

• Copper pipe installation should not be used for

distances longer than 125 cm.

Warmhaus Minerwa

01) 230V AC Main Supply

02) Filling Valve

03) Pressure Relief Valve Outlet

04) Gas Inlet

05) Central Heating Flow (CH)

06) Domestic Hot Water Outlet (DHW)

07) Domestic Hot Water Inlet (DHW)

08) Central Heating Return (CH)

09) Drain Point

10) Condansate Drain

11) Mounting Bracket

595

260

30

55

91

65

50 52

65

90

80

35

67

42,5

1

2

4

9

10

3

8

7

6

5

DHW

G1/2"

379

201

109

CH

G3/4"

GAS

G3/4"

CH

G3/4"

DHW

G1/2"

Figure 7

Minerwa combi boiler dimensions and

connections

11