25

26

OIMM – VENTUS PRO

Coils should be cleaned to remove any accumulation of dust between the fins and tubes should be checked for

any leakage. Cleaning process can be done in 3 ways:

•

vacuum,

•

compressed air,

•

water or steam spray (opposite to the air flow direction).

During the application the water / steam / air pressure should not exceed 5 Bar.

To clean the cooling coil at the hygienic air handling units, the coil can be reached from both sides by taking out

the droplet eliminator from the service door by disassembling the by-pass sheet metal. With the same principle

as there’s no droplet eliminator, the heating coil can be cleaned by reaching both sides from the service doors.

If it is required to withdraw the coil for cleaning and repairing, proceed as follows:

•

drain the water inside the coil,

•

disconnect the coil from piping connections,

•

remove the side panel,

•

remove the bolts by which coil is fixed,

•

withdraw the coil.

To check for leakage in the tubes:

•

clean and dry the coil,

•

fill water inside the tubes,

•

see where the leakage is,

•

drain the water inside the coil,

•

repair the small holes or cracks on the copper tubes by oxyacetylene welding.

Check with water if the welding is successful or not.

After cleaning the coil, drain should be checked and the siphon should be cleaned.

Condition of the filters should be checked once a week. Dirty filters reduces the air flow and hence the capacity. A

manometer, measuring filter pressure drop should be fitted to filter section. If other not stated on the unit, please

use the recommended maximum pressure differentials for different kind or filters that are given on below table.

When manometer reading shows these values, filters should be cleaned or replaced, and these values should not

be exceeded. Synthetic or metallic filter media can be cleaned or washed. However, it is recommended to replace

synthetic media in every two years. New filters should be assembled in the right position that the rough and open

side looks to the dirty air, smooth face to the clean air side.

If there’s gasket on the previous filter frame, to achieve the necessary tightness do not forget to apply the same

media (absolutely same way) on the new filter after renewal.

Other type of filters such as throw away media, bag, absolute and roll filters must be replaced with new filters of

same type, size and efficiency.

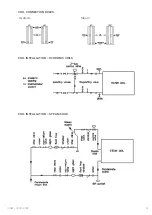

COIL SECTIONS

FILTER SECTIONS

3.10.2

3.10.3