13

14

OIMM – VENTUS PRO

!

Electrical installation and wiring works should be carried out by qualified and competent

electricians.

!

In case of the humidifier, frequency converter, electric heater, EC motor applications their own

installation and connection manuals should be used. For the other equipment the installation

instructions and the wiring diagrams which stuck in the terminal box should be followed.

!

»

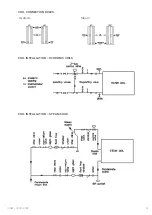

Typical connections – inverter powered ac motors

Direct Driven Fans' motors are adapted to operation in dusty and humid environment (IP55) and their insulation

(F-class) is adapted to cooperation with the frequency converter. No additional means inuring the motor against

conditions of the AHU fans' section are required.

Motors used in our AHUs are by default motors with their own cooling system and with fans built into a shaft.

Supply cabling must be led to the fan's motor via rubber passes located in the back panel of the AHU casing.

One should connect the fan set by means of fault protection appropriate for the applied frequency converter. In

the case of use EC motors or AC motors powering with the use of a converter it is not necessary to connect the

motor’s PTC protection.

Overload protection is realized on the frequency converter by means of activating specified parameters and

introducing the motor’s rated data in accordance with the manual provided together with the frequency converter.

Connecting power cables and clamps in a cable box of one-speed motors

Marking on the engine

rating plate

Motor power supply

3x400V/50Hz

Supplying power to the motor through frequency converter

Converter power supply

3x400V/50Hz

Converter power supply

1x230V/50Hz

230/400V D/Y

400/690V D/Y

x