19

OIMM – VENTUS PRO

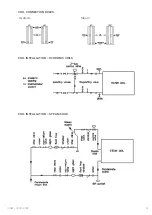

Mat type or steam type humidifiers may be assembled in the unit. For the piping and wiring instructions please

refer to humidifier manufacturer’s manual.

The supply water, overflow / drain piping should be done before the start-up of mat type. The supply piping

should have a valve for cutting off during the maintenance. Before start-up clean the water sump, close the drain

valve and fill the sump with water. The float adjusts the water level. The distance between the water level and

overflow pipe should be 5cm. The water level in the sump is very important that if the water height is usually at

low level the humidification performance will decrease. Check the rotation of the pump, the direction should be

at clockwise. Change the connection of the 2 phases if the direction is opposite. Not to damage the pump do

not operate dry.

Before the start-up of the steam humidifier, wiring and piping should be done, steam supply and drain hose

should be connected to the steam distribution pipe.

For further information about the humidifiers please refer to the humidifier manufacturer’s manual.

Vibration isolators, on which fan + motor assembly is mounted, are locked prior to shipping to avoid damage

during transport. Once the unit is in position and duct connections are made, isolators must be released.

It should be guaranteed that the fan move hasn’t locked.

Wiring work must be carried out in accordance with local standards. Type of start (direct-on-line or star/delta)

should met with local electrical standards. Starters, controls, overload protecting devices, interlocks etc. should

be provided as required. (See page 34) After the start-up, check that direction of rotation of the fan is correct.

The electric heater should be protected against humidity and water. Be sure that the electric heater automatically

cuts off, if the air flow stops.

KLS air handling units can be considered as safe machinery. By means of the compliance statement of the EEC

and of the symbol “CE” on the unit, it is guaranteed that KLS air handling units fulfil the provisions for the safety

and health, on the ground of Machinery Directive 98/37/EC and the European standards. The “CE” mark appears

on every identification label of the unit

In spite of all that, the unit can represent a danger, if it is utilized or serviced not properly or by staff not sufficiently

trained, or if it is used not in conformity with general provisions. For this reason, we intend to explain to the user

the concept of safety referring air handling units and to inform him of possible danger and consequent measures.

Internal area of the units near to the moving parts (fans, motors, pumps etc.) end electrical parts, hot sections

(hot water and steam coils, piping, fittings and control devices) are considered as “danger zone”. In order to be

able to access to these areas, it is necessary to provide oneself with the proper key tools. The operators are

responsible for transport, installation, start up, service and maintenance including cleaning and repairing.

Possible hazards regarding to the air handling units are:

•

danger to the operator’s safety,

•

damages to the unit,

•

possibility to affect the efficiency of the unit work

HUMIDIFIERS

SUPPLY AND RETURN FANS

ELECTRIC HEATER

SAFETY

3.7.5

3.7.6

3.7.7

3.8