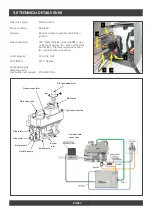

7.0 CONCENTRIC FLUE SYSTEM

The concentric flue system is composed of an inner- and an outer tube. These tubes are concentrically arranged;

through the inner tube, the combustion gases are evacuated and the fresh combustion air is supplied between

the inner and outer tube.

7.1 Components of the concentric flue system

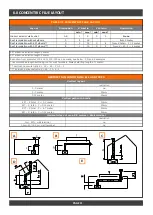

Different connections are possible using the concentric flue system. These are

through the roof face

and

through the exterior wall

. There are various options for mounting the layouts for this system, however, there

are a few important requirements/conditions:

The maximum recommended vertical flue length is 12 metres (the sum of the flue length and the

Calculation lengths for the bends).

90° bends have a 2-metre horizontal calculation length.

45° bends have a 1-metre horizontal calculation length.

The outlet can be installed at any point on the roof face or exterior wall (supply and discharge in an

identical pressure area), but must meet applicable regulations.

Ducts may not be insulated.

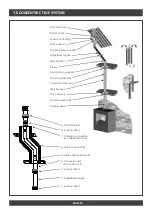

7.2 Construction of concentric flue system

-

indirect wall connection

The outlet may be installed in the wall, taking any hindrance to the surrounding area into consideration,

according to national, regional, local standards and regulations. Ensure wind pressure on the flue terminal

is not too extreme, such as a balcony, flat roof, corners and in small alleys etc., as this may negatively

influence the unit efficiency.

Provide a recess in the exterior wall of around 155 mm for concentric 100-150, and 205 mm for concentric

130-200. (in a flammable wall ensure there is 50 mm of extra space around the outer pipe and use

fireproof casing) and fix the exterior wall duct with the wall plate to the outer side of the wall. The wall

plate of the exterior wall duct must be sealed sufficiently against the wall on the outside, to avoid moisture

and/or flue gas leaks into the living space.

The flue should be cased if necessary. Sufficient fireproof measures must also be taken when the flue is

being mounted along flammable materials.

Determine the position of the unit and outlet and begin construction of the flue with the connection on the

unit, paying attention to the direction of installation and connecting the elements by means of locking

bands.

An adjustable length can be used between the bends or when connecting to the unit. If necessary, use

wall brackets to support the flue.

7.3 Construction of concentric flue system

-

roof termination

The flue terminal can be located at any random place on the roof face (supply and exhaust in identical

pressure areas) and must meet the applicable rules and regulations.

A roof flashing for a flat roof or a lead flashing for sloping tiled roofs can be used for a watertight

connection. Use various elbows for making the proper connection, if required. The recess in the roof

decking should be 5 cm larger all around, to ensure sufficient fire resistance.

One needs to take into account the regulation regarding fire resistance between rooms (See national, re-

gional, local standards and regulations). A casing made of fireproof material (e.g. 12 mm Promatect fire

resistant plate) must be used at 25mm from the outside duct.

Determine the position of the unit and outlet and begin construction of the flue with the connection on the

unit (always 1 metre vertical first), paying attention to the direction of installation! The flue must be

installed dripless. Connect the elements by using locking bands. Ensure the gas tightness of all

connections is correct.

An adjustable length can be used between the elbows or when making the connection to the unit and/or

the roof terminal. Use 2 wall brackets to support the flue on each floor.

NOTE: Ensure the restriction plate in the fire is mounted in the correct manner, as indicated in

these instructions.

The correct restriction plate will provide the unit with the most optimal efficiency, flame

image and combustion. Mounting an incorrectly placed restriction plate may cause malfunction of the unit.

PAGE 12

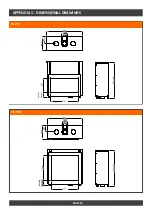

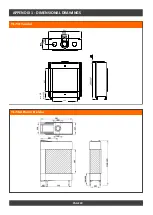

Summary of Contents for TL73

Page 1: ...INSTALLATION INSTRUCTIONS FOR MODELS TL73 TL73H TL73T TL73RD ...

Page 20: ...APPENDIX 2 INSTALLATION EXAMPLES PAGE 21 1 2 3 4 MAX 1500 ...

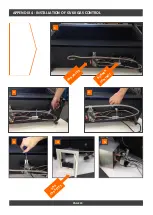

Page 21: ...APPENDIX 2 INSTALLATION EXAMPLES PAGE 22 4 5 6 ...

Page 22: ...APPENDIX 3 PREPARATION AND INSTALLATION PAGE 22 1 1 2 3 4 5 6 7 ...

Page 27: ...APPENDIX 6 ARRANGEMENT OF VARIOUS BURNER FILLINGS PAGE 29 PEBBLES 1 2 ...