17

EN

While the sludge remover unit is filling, with the compressor running, do not pull the power supply

cable.

3. Open the water supply.

4. Read the minimum flow rate and let it stabilize. If the minimum flow speed of 0.5 m / sec. is not

reached, cleaning cannot be performed properly. In this case, clean the system by segments.

5. Press the “Water + Air (pulses)” program key.

And clean.

6. Alternate the two Pulse cleaning and Continuous compressed air cleaning about every 10min to

clean the installation effectively.

7. The cleaning process is complete when there are no more visible traces of residue at the outlet. To this

effect, we advise to run the water at the outlet of the water points through filtering strainers with a mesh of about

100 μ.

8. After cleaning, stop the sludge removal unit. The compressor must not be running. The filling process (8 bar)

must be finished.

9. Then close the water supply.

10. Disconnect the VIRAFAL® from the electric network.

11. The cleaning controller must be disconnected from the test pipe, all couplers must be fitted properly. A

sealing test must then be performed.

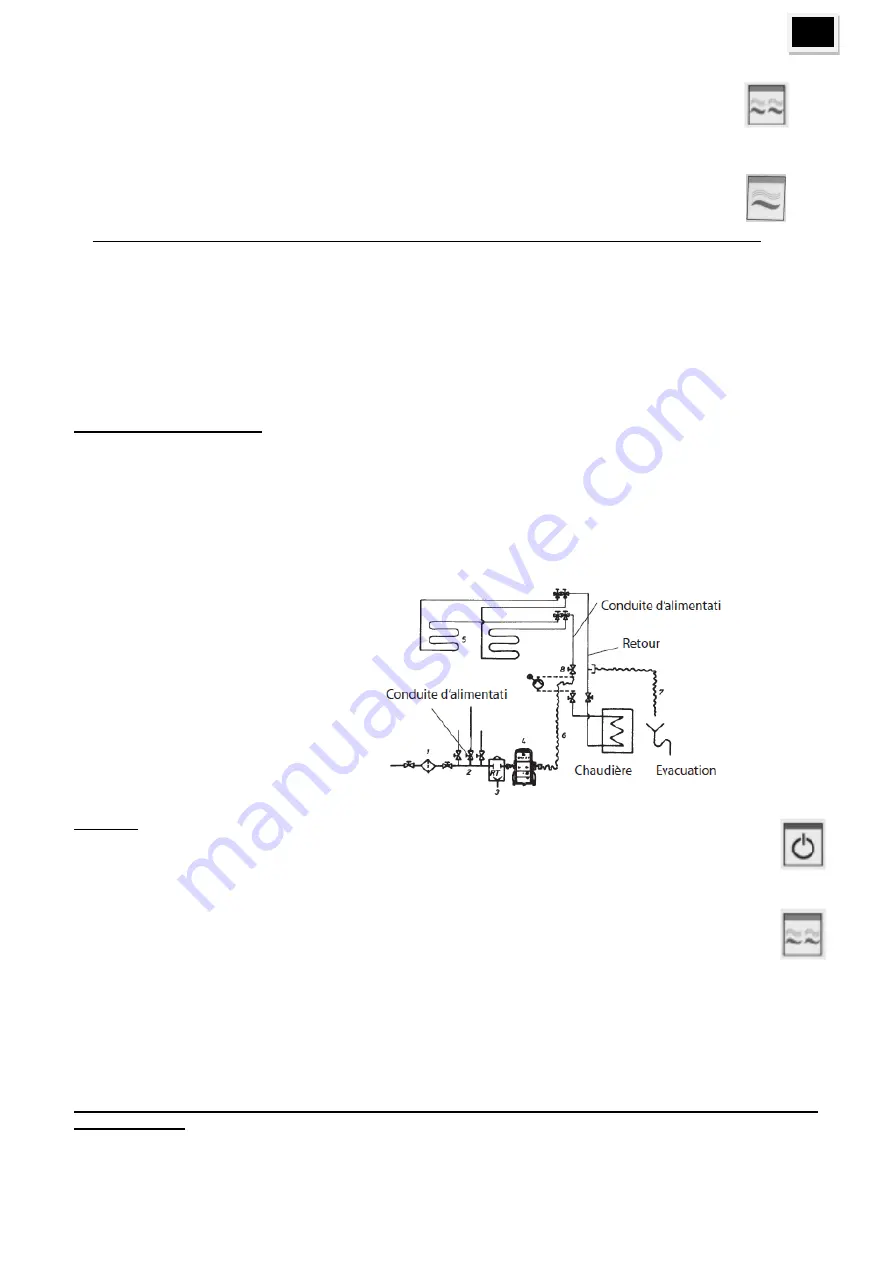

6.3. Cleaning floor heaters

1. Separate the water inlet pipe from the boiler.

2. To protect drinking water, a tube or separator system must be fitted upstream the rinsing

compressor as per EN 1717.

3. Separate the return or close it and fit an evacuation pipe. In addition, the pipe must be

extended and fastened to a sufficiently large evacuation.

4. In case of low water pressure, clean the heating system by section.

1 Fine filter

2 Drinking water dispenser

3 Pipe disconnector

4 VIRAFAL® sludge removal unit

5 Floor heater circuit

6 Connection pipes

7 Evacuation pipe

8 Stop valve

9 Evacuation

Cleaning:

1. Flip the switch to "Without additive".

2. Press the “On / Off” program key. The compressor fills the pressurized tank automatically. Do not

remove the electric plug when the pressure tank is filling and the compressor running.

3. Open the water inlet.

4. Press the “water + air (pulse)” program key and clean.

5. Cleaning is complete when no evacuation is seen. To this effect, we recommend to leave the water

flowing from the collection point through a strainer with a mesh size of about 100 μl.

6. After cleaning, stop the sludge removal unit.

7. Then close the water supply.

8. Disconnect the VIRAFAL®

9. The compressor must not perform any filling. The filling process (8 bar) must be finished. Separate the sludge

removal unit from the installation, refit all couplings properly. Then sealing must be checked.

6.4. Special instructions for cleaning drinking water pipes on a new installation (before the 1

st

start-up of

the installation)

As set out in the EN 806-4 standards, recently installed drinking water pipes must be cleaned before use,

knowing that performing this cleaning operation using a pulsated water/air mix improves the cleaning result.

Summary of Contents for VIRAFAL

Page 57: ...57 EL 3 2 RCD RCD 3 3...

Page 58: ...58 EL 3 4 VIRAX 3 5...

Page 64: ...64 EL 7 2 5 5 5 bar ON 7 3 8 2002 96 CEE...

Page 93: ...93 RU 3 1 3 2 3 3...

Page 94: ...94 RU 3 4...

Page 95: ...95 RU VIRAX 3 5 3 6 VIRAFAL 30 C 40 DVGW DIN 1988 SVGW VGW DIN 1988 DIN 50930...

Page 100: ...100 RU 7 VDE 16 A 7 1 10 50 15 50 7 2 5 5 5 ON 7 3 a a N...

Page 101: ...101 RU 8 2002 96 CEE...

Page 119: ...119...