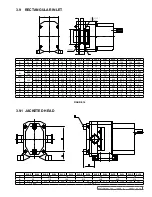

fIGURE 86

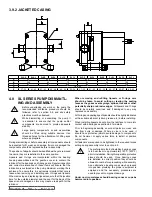

fIGURE 89

fIGURE 90

fIGURE 87

8.09

fIGURE 88

8.19

8.20

fIGURE 85

8.08

8.09

fIGURE 92

8.06

8.17

8.18

fIGURE 93

8.04

8.03

fIGURE 91

3.01

7.03

4.07

SECTION TSM 288

ISSUE

A

PAGE 25 OF 36

• Install the slinger (5.15)

NOTE:

the slinger has raised sections on the internal diameter,

which press onto the shaft

• Install the O-ring (8.19) onto the sleeve (8.20) and then

install the sleeve onto the shaft and secure with the grub

screws (8.14)

NOTE:

The shaft has two location grooves which the grub

screws in the seal sleeve locate into. (See Figure 89 and

Figure 90)

The washers overlap the seal bore – this locates and provides

drive to the seal.

• Install the seal washers (8.08) and the seal screws (8.09)

• Install the O-ring (8.06), lip-seal (8.17) and the cir-clip (8.18)

into the seal housing and then install the seal housing (8.16)

into the casing

• Install the O-ring (8.04) onto the static seal (8.03) and then

install the static seal into the casing – ensure that the location

slots line up with the pins in the seal housing

• Install the guard (7.03) and casing (3.01) and secure with

screws (4.07) (see section 6.2 for torque settings)