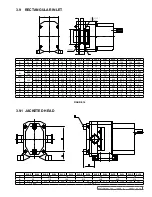

fIGURE 60

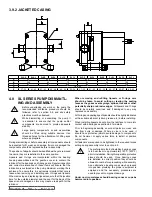

3.01

4.01

4.07

fIGURE 61

5.17

fIGURE 62

fIGURE 63

fIGURE 59

4.07

SECTION TSM 288

ISSUE

A

PAGE 21 OF 36

• Install the casing (3.01) onto the bearing housing (4.01) and

use the bolts (4.07) to secure the casing (3.01)

NOTE:

without the gearbox cover spacers are required to

ensure the casing is fully clamped

• The front clearance is set by machining the clearance

spacer (5.17)

• Using a depth micrometer check the front clearance (Distance

from the front of the rotor to the front of the casing) and

adjust the width of the front clearance spacer as necessary

to set the front clearance see section 6.1 for pump head

clearances

NOTE:

When assembling the pump with a new front clearance

spacer the rotor will be proud of the casing.

When the front clearance spacer has been machined to

the correct width make sure that the spacer kept with the

respective shaft.

4.2.7 fINal assEMblY

• When the front clearance spacers have been set install the

5mm (0.19”) pins (5.19) one per shaft.

The pin serves two main purposes

1) They secure the front clearance spacer

2) It provides anti-rotation for the seal sleeve and the seals

NOTE:

When installing the pins use a locking compound like

Loctite 648 or similar

• Install the shaft sleeve O-ring (5.21) into the shaft sleeve

(5.18) and then install the assembly onto the shaft

4.2.6 sETTING fRONT ClEaRaNCE

slG

• Remove the rotor retainers (2.02), rotors (2.01) and install

the dowels (4.07) into the bearing housing (4.01)