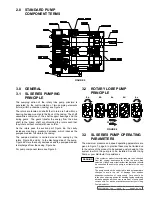

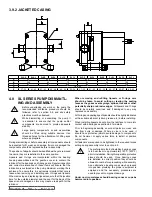

fIGURE 48

6

4

7

2

8

1

5

3

5.05

fIGURE 47

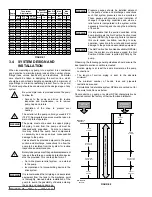

5.03

fIGURE 49

MaCHINEd

faCE

fIGURE 50

5.11

5.05

fIGURE 51

5.22

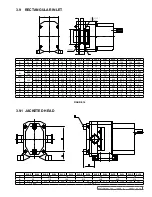

TWO TIMING

MaRKs ON dRIVE

ONE TIMING

MaRK ON laY

fIGURE 52

SECTION TSM 288

ISSUE

A

PAGE 19

OF 36

• Install the bearing cone (5.03) and the bearing pre-load

spacer (5.05) secure using the M12 screws (5.20) see Figure

48 for the correct order to tightening the screws also see

section 6.2 for torque settings.

4.2.2 ROllING TORQUE /

PRE-lOad

Use a torque meter to check the rolling torque see section 6.2

for torque settings

The rolling torque as standard with new components will be

under the required amount and will require adjustment.

• To adjust the pre-load modify the size of the bearing pre-load

adjustment spacer (4.10)

NOTE:

When machining the spacer make sure small cuts are

taken i.e. 0.02 mm – 0.03

4.2.3 fINal PRE-lOad assEMblY

• When the pre-load is set remove the bearing pre-load spacer

(5.05) and install the front lip-seals (5.11) – refer to lip-seal

setting distances section 6.3

• Install the gearbox O-ring (5.22) and secure the pre-load

spacer (5.05) with the M12 screws (5.20) see Figure 48 for

the correct order to tightening the screws also see section

6.2 for torque settings.

4.2.4 TIMING – MUlTIlObE ROTORs

ONlY

• To set the timing marks on the gears (5.06) lay the gears

next to each other and line up the keyways, You can now

punch three timing marks to show the correct alignment of

the gears see Figure 52