11

PLANING DEPTH ADJUSTMENT

Planer front footplate (

6

) is movable and it allows for planing depth

adjustment.

Planing depth can be adjusted with the knob for planing depth

adjustment (

1

) and the range is 0 –

2

mm, shown on the planing depth

scale (

7

) located on its circumference (

fig. F

).

OPERATION / SETTINGS

SWITCHING ON / SWITCHING OFF

The mains voltage must match the voltage on the rating plate of

the planer. Hold the planer with both hands when starting up and

during operation.

The planer features switch that protects against unintentional starting up.

Switching on:

•

Press the switch lock button (

3

)

(

fig. G

).

•

Press the switch button (

2

).

Switching off:

•

Release pressure on the switch button (

2

).

Hold the planer firmly with both hands before switching it on.

Switch on the planer only when the front footplate rests on the

material that you plan to process and the planer blades do not

touch material. This position prevents too early contact of blades

with material. Start the work only after the planer reaches its top

rotational speed.

When using the planer, try to position planer footplate and surface

of processed material in parallel. Guide the planer with both hands,

move it smoothly and continuously on the material surface. Effects

of work depend on speed of planer movement and depth of planing.

Coarse processing uses bigger planing depth. During fine processing

it is recommended to set small planing depth and to proceed with

work in few runs.

Do not press the planer too hard. Pressure should be moderate

and uniform on the whole surface of contact of foot and processed

material. Applying too big pressure causes undesirable drop

of rotational speed, motor overheating, damage of processed

material and parts of the planer. Make periodic breaks in

operation.

DEEP PLANING

You can use the deep planing guide and the parallel guide to make

hollows in material.

•

Attach the parallel guide (

9

) and the deep planing guide (

12

).

•

Set planing width and depth.

•

Process the material (

fig. H

).

PROCESSING CORNERS (CHAMFERING)

V-grooves (

18

) located on the front footplate (

6

) (

fig. I

) allow for quick

processing (chamfering) of edges of processed material. Place one of

the V-grooves on the edge of processed material and move the planer

forward, make sure to keep the

45

0

angle (

fig. J

).

OPERATION AND MAINTENANCE

Unplug the power cord from mains socket before commencing

any activities related to installation, adjustment, repair or

maintenance.

•

Soft brush or compressed air are best for cleaning the planer.

•

Do not use abrasive objects for cleaning the planer.

•

Do not clean with water or chemical cleaning agents.

•

Clean the planer regularly, optimally after each use.

•

Always keep the planer and ventilation holes clean.

•

Store the planer in dry place, beyond reach of children.

•

In case of excessive commutator sparking, have the technical

condition of carbon brushes of the motor checked by a qualified

person.

•

When the work is finished empty the dust bag, next wash it in warm

water with soap and dry it thoroughly.

REPLACEMENT OF PLANER BLADES

Use only cutting heads that are recommended by the

manufacturer, and that include blades, drum, blade fixing parts,

appropriate bolts and spindle. Always replace both blades at a

time.

New blades must be of the same size and weight as old ones.

Otherwise the head may vibrate, processing may be improper

and it may damage blades or planer head. Too fast advance

considerably reduces efficiency and quality of work and durability

of blades. Use only sharp blades. Avoid blunting the blades.

Replace blades as soon as it is necessary.

•

Use the spanner (included) to loosen fixing screws (

15

) of the blade

(

16

) (

fig. K

).

•

Turn the head (

17

) by 1

8

0

0

and repeat this operation for the second

blade.

•

Press in the removable shield (

21

) and slide the blades out.

•

Replace the blades with new ones and proceed with installation in

reverse sequence of disassembly.

•

Make sure the blades are positioned symmetrically in the guide of

the head (

17

).

•

Tighten screws (

15

) that fix blades alternately and with the same

force.

Ensure screws and bolts are tightened after blades are installed in

the head. Failing to do so may cause damage of the planer or the

user’s body injury. Blade edges must be parallel to the head drum

surface. Otherwise the processed surface will not be flat and even.

Use only head that is supplied with the product, head supplied by

the manufacturer or its authorized distributor.

REPLACEMENT OF DRIVE BELT

Planer does not work properly if drive belt is worn. Belt replacement

is necessary.

•

Unscrew fixing screws and remove the drive belt cover (

4

).

•

Remove the drive belt by turning the pulleys manually and pulling

the belt off.

•

To install new drive belt do as follows:

– put the drive belt onto smaller pulley,

– rotate pulleys and draw the drive belt over the bigger pulley.

•

Ensure the belt is correctly set on both pulleys.

•

Install drive belt cover (

4

) and tighten fixing screws.

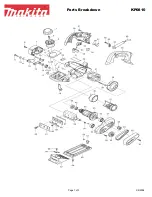

Summary of Contents for 52G607

Page 2: ......

Page 3: ...3 1 2 3 4 8 11 9 10 14 7 6 12 13 5...

Page 4: ...4 C 5 D 8 11 9 10 F 7 1 6 G 3 2 press H max 3mm I 6 18 J 45 o K 21 16 17 15...

Page 16: ...16 12 13 12 6 1 0 2 7 F 3 G 2 2 9 12 V 18 6 I V 450 J 15 16 K 17 21 17 15...

Page 19: ...19 3 G 2 2 9 12 H V 18 6 I 7 V 45 J 15 16 K 17 21 17 15...

Page 41: ...41 5 C 10 11 9 10 8 D 12 13 E 12 6 1 0 2 mm 7 F 3 G 2 2 9 12 V 18 6...

Page 49: ...49 12 13 12 6 1 0 2 mm 7 F 3 G 2 2 9 12 V 18 6 I V 450 J 15 16 K 17 21...

Page 56: ......